Blane

Active Member

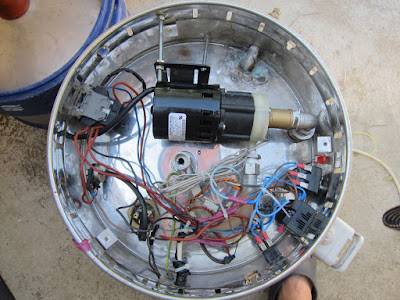

After nine months of messing around I finally got to the point where I could do some sea trials with no loss of life or property. My inspiration was based largely on this thread:

My new brew system, a brutus 10 with some nice modifications

Instead of gas, I went the electric route where I'm using a CFC as an external pseudo HERMS heat exchanger:

My new brew system, a brutus 10 with some nice modifications

Instead of gas, I went the electric route where I'm using a CFC as an external pseudo HERMS heat exchanger:

:rockin:

:rockin: