Brewpastor

Beer, not rocket chemistry

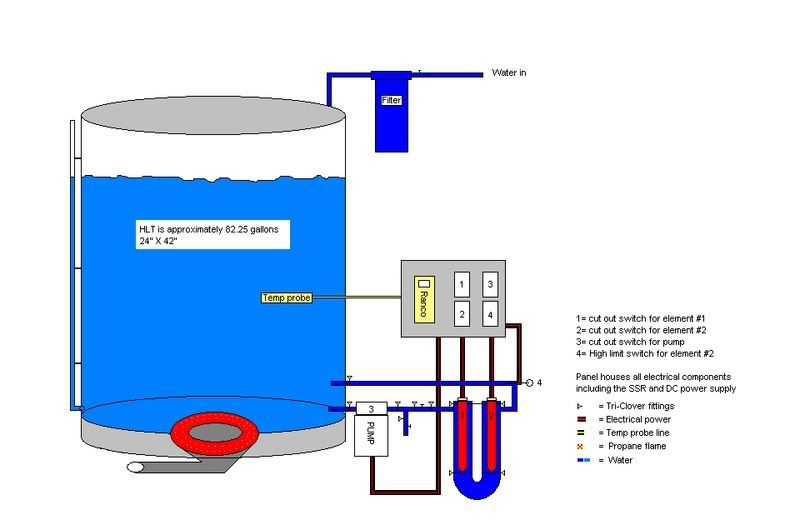

OK, I can get a 5500 watt element for my electric heater project. That would mean I could heat 30 gallons in my HLT to 180 degrees in 1 hour and 41 minutes for less then 60 cents. The 4500 watt element I have will take 25 minutes longer. What do people think? Do I go for it?