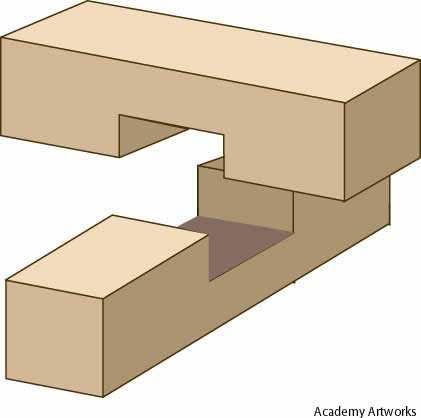

Homemade apple grinder and press. Test run. Used 1/4 bushel and made 3 quarts juice. Press has nearly 3 bushel capacity. Garbage disposal is 1 1/4 horsepower from Costco mounted on a stainless steel sink. Press is 2 X 4 's mostly screwed and glued. Box and frame are oak. Pressboards are oak plywood 3/4 " thick. Bottle jack is 6 ton. Cheeses are polyester curtain material from the fabric store.

Last edited by a moderator: