I have two auber syl-2342 PID controllers, two chugger pumps from usa pumps (same as March 809, got two stainless for $250 here ) and two STC 2w160 solenoid valves.

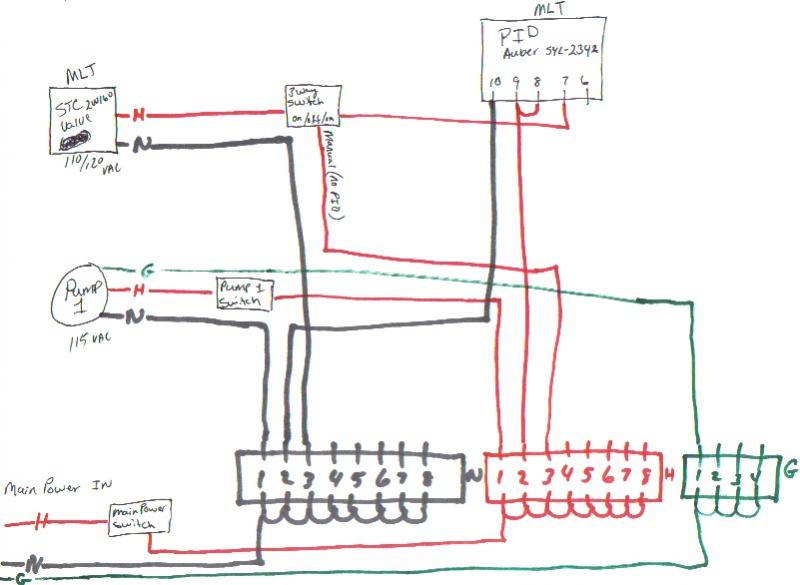

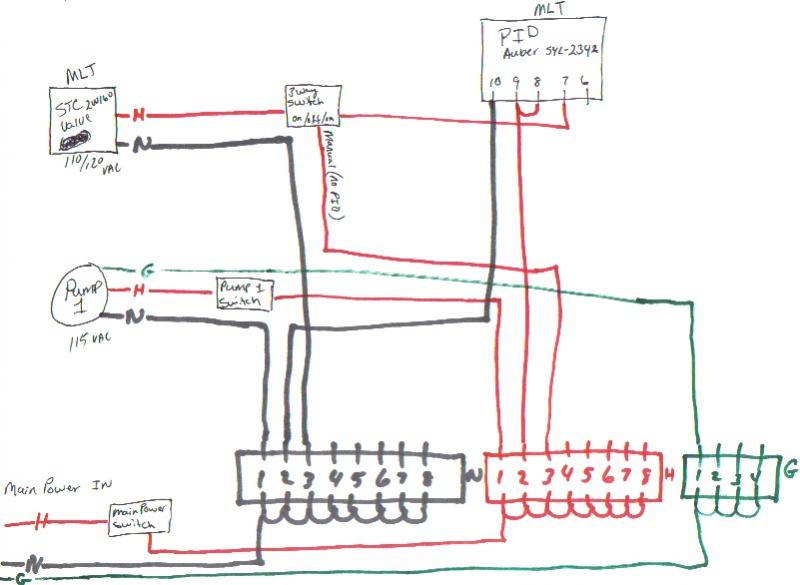

Here is a drawing of how I believe I should wire everything into a control panel. I'm not an electrician, or artist, but this is what I have figured out by reading threads here and other online forums. Can you guys take a look at this and tell me if this will work? Also, if I wanted to add fuses would that be done by putting the fuse in the neutral line to the object I want to protect?

I thought I would use terminal strips to help keep things organized. I added a small one for a ground since the pumps have three wires. Is my thinking correct on this too?

What kind of testing equipment should I be using to test these connections before plugging this thing into a power source?

Here is a drawing of how I believe I should wire everything into a control panel. I'm not an electrician, or artist, but this is what I have figured out by reading threads here and other online forums. Can you guys take a look at this and tell me if this will work? Also, if I wanted to add fuses would that be done by putting the fuse in the neutral line to the object I want to protect?

I thought I would use terminal strips to help keep things organized. I added a small one for a ground since the pumps have three wires. Is my thinking correct on this too?

What kind of testing equipment should I be using to test these connections before plugging this thing into a power source?