shortyjacobs

Well-Known Member

I'm working on getting my new brewery up and running. Did my first autotune try today.

I gave two AT tries, one from 50F to a SV of 165F, and one from 145F to a SV of 165F. The first time, the temp overshot to 208, at which point I shut it down. The second time, it overshot to 195, at which point I shut it down.

40A SSR w/ standard heatsink, 5500W element pulling ~23A IIRC, SYL-2352 running the SSR.

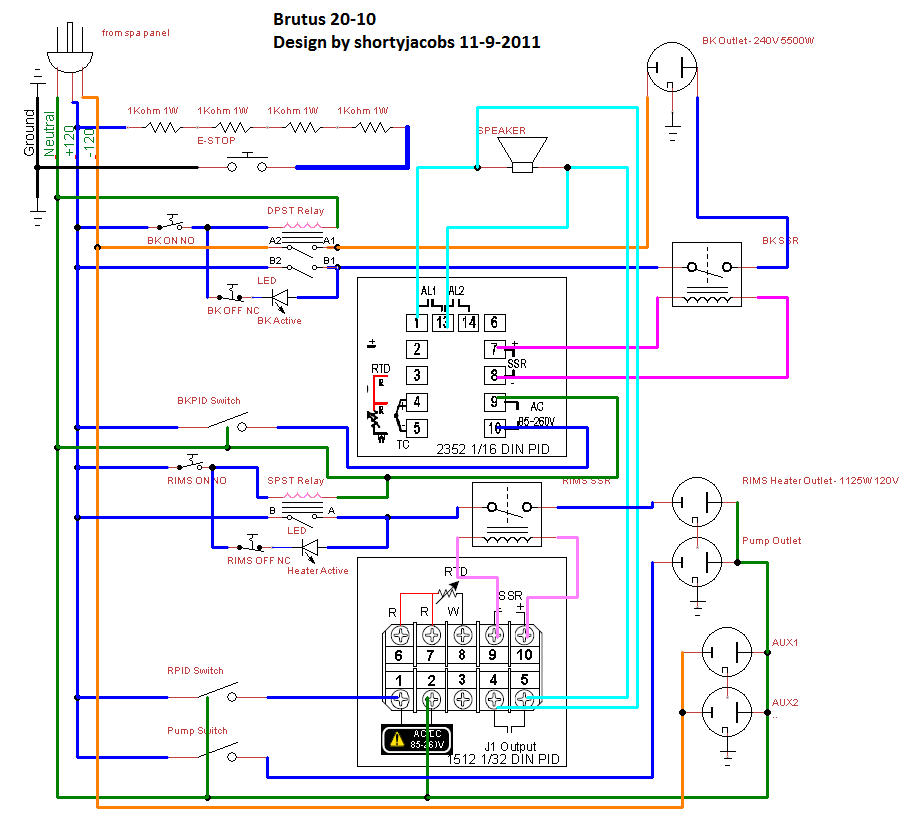

Wiring diagram here: https://www.homebrewtalk.com/f170/diagram-critique-my-brutus-20-10-a-279903/

Once the PID passed the SV during the autotunes, the "on" light on it shut off. So did the LED on the SSR. But the element was pumping out heat. Not as much as before, when the PID was at 100% for the AT, but it was still boiling water. When I power cycled the Line/Load side of the SSR, that fixed the problem and allowed the system to start cooling.

So it looks like my SSR is sticking "on". Power cycling it after it's stopped getting a control signal unlatches it, at least that's the way I read it. OH, and the SSR heatsink is frigging HOT during all this, (even once the SSR has supposedly shut "off"). Like we're talking burn your skin hot. It's in an open box with plenty of ventilation.

So, blown SSR?

I gave two AT tries, one from 50F to a SV of 165F, and one from 145F to a SV of 165F. The first time, the temp overshot to 208, at which point I shut it down. The second time, it overshot to 195, at which point I shut it down.

40A SSR w/ standard heatsink, 5500W element pulling ~23A IIRC, SYL-2352 running the SSR.

Wiring diagram here: https://www.homebrewtalk.com/f170/diagram-critique-my-brutus-20-10-a-279903/

Once the PID passed the SV during the autotunes, the "on" light on it shut off. So did the LED on the SSR. But the element was pumping out heat. Not as much as before, when the PID was at 100% for the AT, but it was still boiling water. When I power cycled the Line/Load side of the SSR, that fixed the problem and allowed the system to start cooling.

So it looks like my SSR is sticking "on". Power cycling it after it's stopped getting a control signal unlatches it, at least that's the way I read it. OH, and the SSR heatsink is frigging HOT during all this, (even once the SSR has supposedly shut "off"). Like we're talking burn your skin hot. It's in an open box with plenty of ventilation.

So, blown SSR?

). But yea, SSRs block current. A FET is like a big variable resistor that gets pinched closed as the gate voltage drops.

). But yea, SSRs block current. A FET is like a big variable resistor that gets pinched closed as the gate voltage drops.