beertastic

Well-Known Member

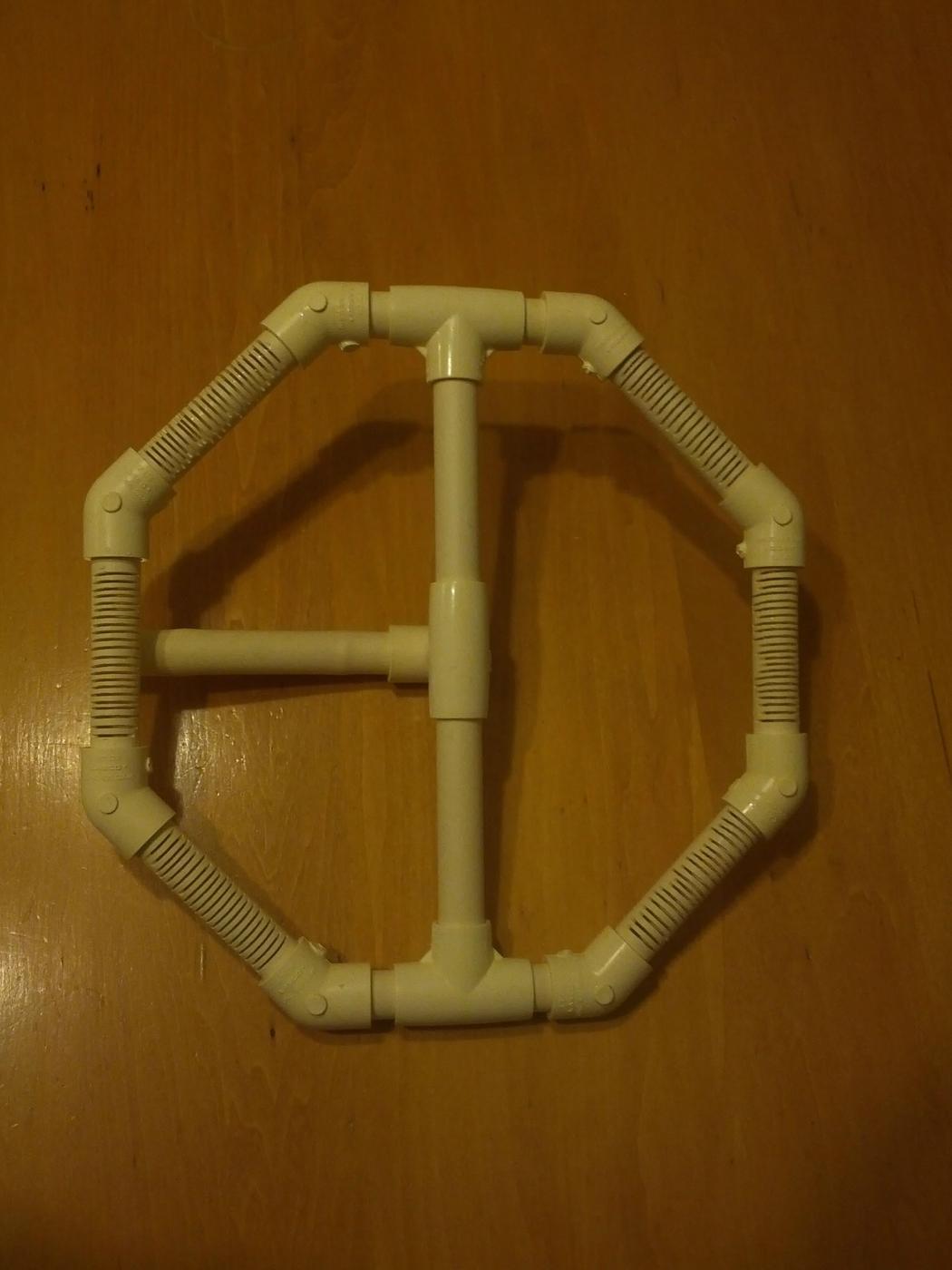

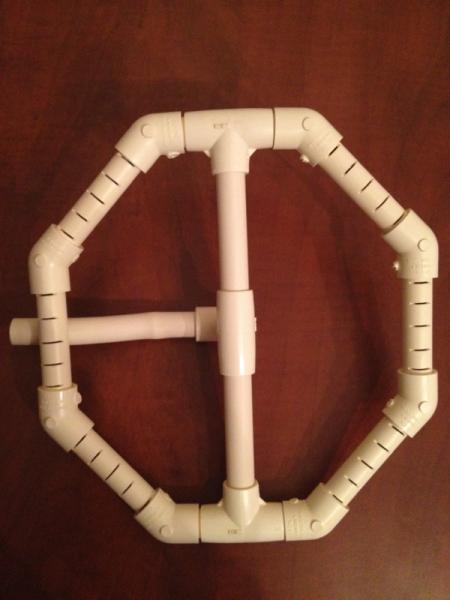

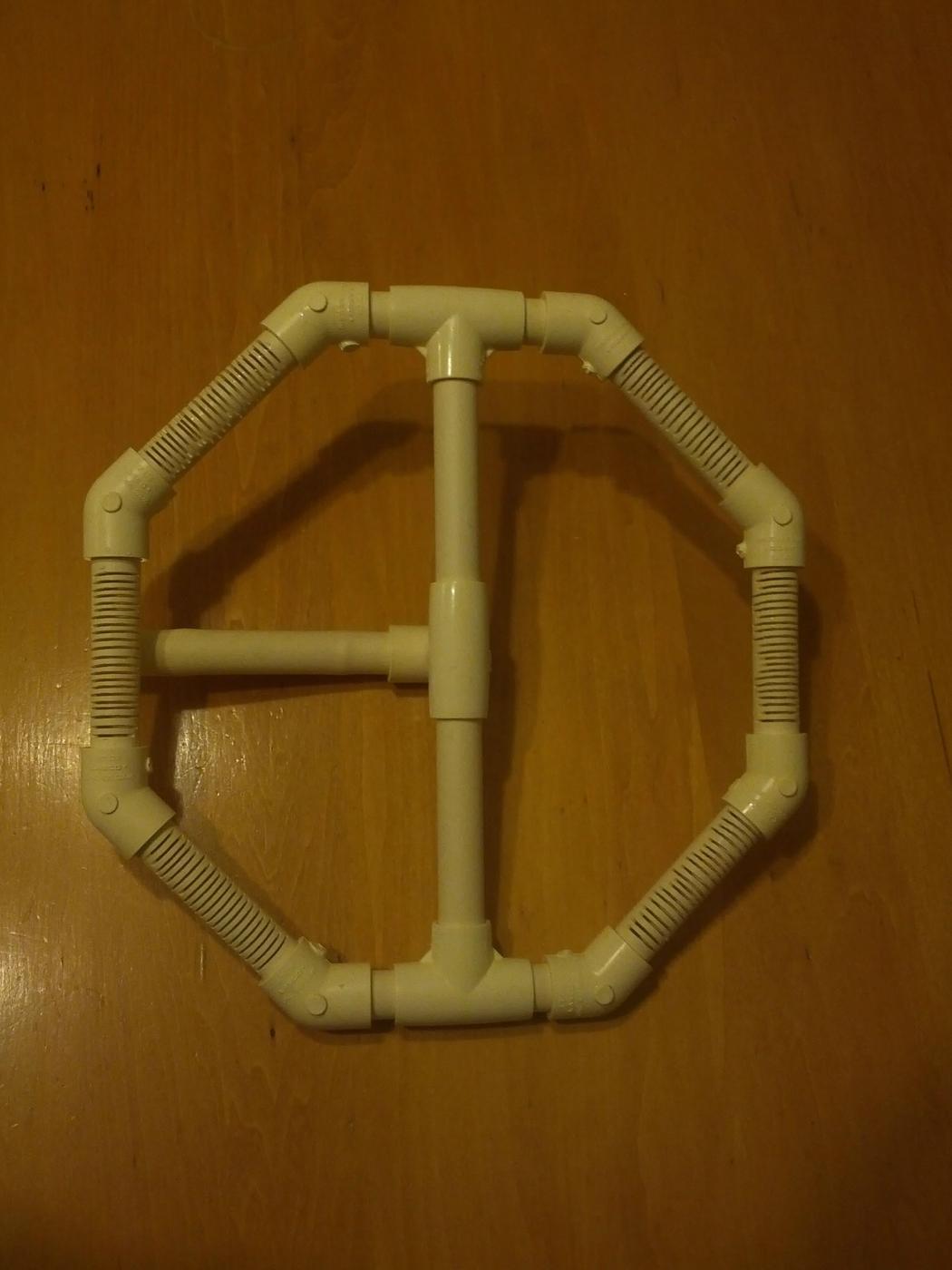

So I tried my hand at building a CPVC manifold, since I was tired of a floating braid and mangling it during stirring.

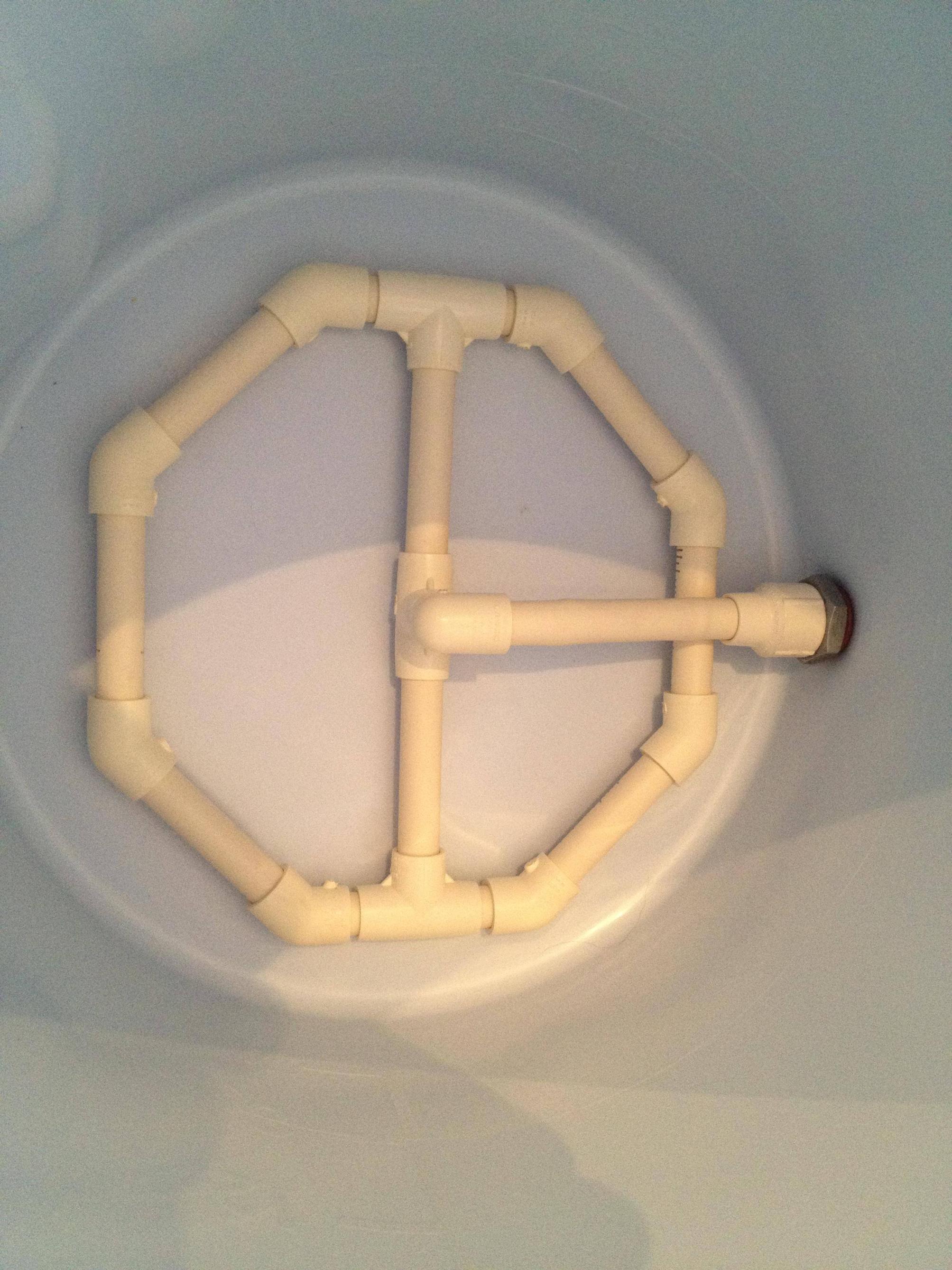

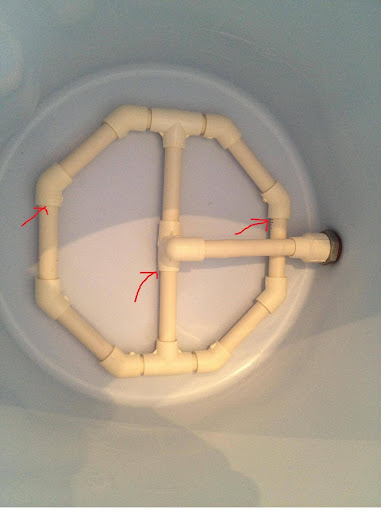

I gave this manifold a test run awhile ago, and it failed. When I first opened up the valve, a ton of grain came out very quickly. Then just stuck immediately afterwards. I ended up attaching a bike pump to the valve/hose to force the grain back out of the manifold. I finally got a very slow run, but with tons of grain chunks. I put a paint strainer bag in the kettle to help filter the grain even further. I had to repeat the process for the (batch) sparge. My crush is done at the lhbs, and looks like a good crush to me (though I lack experience). I'm pretty sure it wasn't over crushed, at least not significantly so.

The manifold did not fall apart during the whole process. What did I do wrong? Too many slits? Slits too big? The slits are cut with a hacksaw.

I gave this manifold a test run awhile ago, and it failed. When I first opened up the valve, a ton of grain came out very quickly. Then just stuck immediately afterwards. I ended up attaching a bike pump to the valve/hose to force the grain back out of the manifold. I finally got a very slow run, but with tons of grain chunks. I put a paint strainer bag in the kettle to help filter the grain even further. I had to repeat the process for the (batch) sparge. My crush is done at the lhbs, and looks like a good crush to me (though I lack experience). I'm pretty sure it wasn't over crushed, at least not significantly so.

The manifold did not fall apart during the whole process. What did I do wrong? Too many slits? Slits too big? The slits are cut with a hacksaw.