I'm certain this has to have been covered at one point here, but I've been searching for quite a while and not finding a clear answer.

Basically I'm just getting started in brewing. I have all the equipment I need to do extract batches. But being that I am a bit of a perfectionist, I would really like to get into AG brewing at some point. Not only for the per batch cost savings, but moreso so that I can create my own beers rather than going by the kit.

My current equipment consists of:

10gal SS Kettle (no valves or anything in it)

Propane burner (from a turkey fryer kit)

2 6gal glass carboys

2 5gal glass carboys

2 6 gal plastic fermenter buckets

25' copper IC wort chiller

I won't be bottling, as I've just completed my kegerator to hold 4 corny kegs.

Which at the moment I have 3 kegs, but will be getting at least 1-2 more in the future.

on a side note I also have a rubber coated miller keg and the tools to cut the top off.

So my question is, what equipment would I need to start doing 5gal AG batches? I'm not sure how to best utilize my current equipment to make the change cost me the least.

I'm guessing (and this is definitely just a guess!) that I can probably use the Miller keg as a MLT? I've read the rubber does provide some insulation for the mashing process. But again, not sure if that's my best bet.

Also, I don't have a 220v circuit near my brewing equipment, or the ability to add one. So that puts out any 220v heating elements that I may have been able to use with the rubber keg.

Basically I'm just getting started in brewing. I have all the equipment I need to do extract batches. But being that I am a bit of a perfectionist, I would really like to get into AG brewing at some point. Not only for the per batch cost savings, but moreso so that I can create my own beers rather than going by the kit.

My current equipment consists of:

10gal SS Kettle (no valves or anything in it)

Propane burner (from a turkey fryer kit)

2 6gal glass carboys

2 5gal glass carboys

2 6 gal plastic fermenter buckets

25' copper IC wort chiller

I won't be bottling, as I've just completed my kegerator to hold 4 corny kegs.

Which at the moment I have 3 kegs, but will be getting at least 1-2 more in the future.

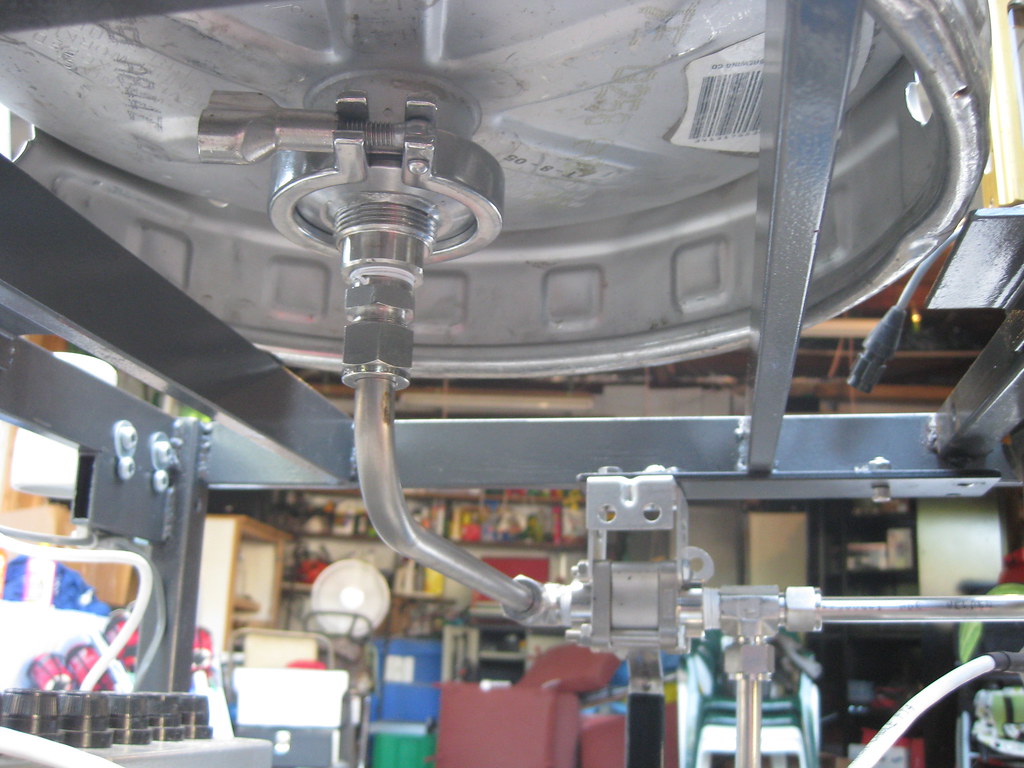

on a side note I also have a rubber coated miller keg and the tools to cut the top off.

So my question is, what equipment would I need to start doing 5gal AG batches? I'm not sure how to best utilize my current equipment to make the change cost me the least.

I'm guessing (and this is definitely just a guess!) that I can probably use the Miller keg as a MLT? I've read the rubber does provide some insulation for the mashing process. But again, not sure if that's my best bet.

Also, I don't have a 220v circuit near my brewing equipment, or the ability to add one. So that puts out any 220v heating elements that I may have been able to use with the rubber keg.