CoalCracker

Well-Known Member

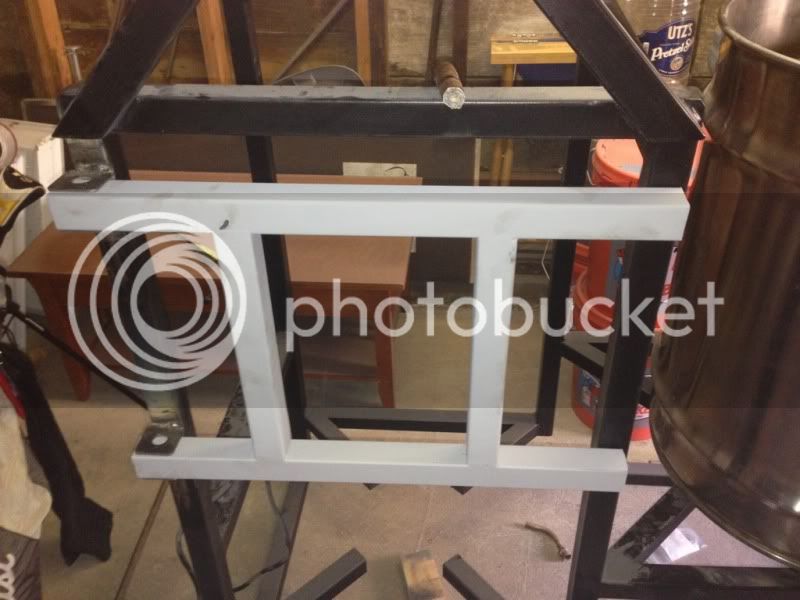

I do like that mount. Seems plenty sturdy. Once I get the stand in it's final resting place, I'll have to entertain that idea.

Anyone have any other ideas as far as chilling goes? Still kinda stuck. I'll be getting the 1/2" x 50ft chiller kit from coppertubingsales.com for the HEX. I can always throw some ice in the HLT and use the HEX as a prechiller if I need to in the summer. I know a plate chiller would work best but after cleaning them on my last system and seeing what comes out even after it's "clean" i'm really having a hard time settling on buying one.

Just thought about something else. I can use the HEX coil as an immersion chiller first, bring the temp down to say 100, then take it out and place it in the HLT with some ice to chill the water and run it through the counterflow to bring it the rest of the way.

Anyone have any other ideas as far as chilling goes? Still kinda stuck. I'll be getting the 1/2" x 50ft chiller kit from coppertubingsales.com for the HEX. I can always throw some ice in the HLT and use the HEX as a prechiller if I need to in the summer. I know a plate chiller would work best but after cleaning them on my last system and seeing what comes out even after it's "clean" i'm really having a hard time settling on buying one.

Just thought about something else. I can use the HEX coil as an immersion chiller first, bring the temp down to say 100, then take it out and place it in the HLT with some ice to chill the water and run it through the counterflow to bring it the rest of the way.