Hey all. I'd like to get some ideas as to how to go about doing this and whether or not you all think it is a good idea.

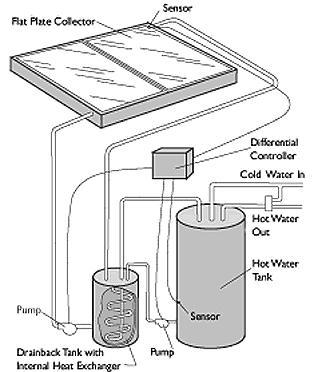

In Sept I've gotten the ok from SWMBO that I can build a shed/brew house. The roof of this shed is going to face South so my thought was to put a solar hot water heater on the roof and hook it up to a HERMS rig.

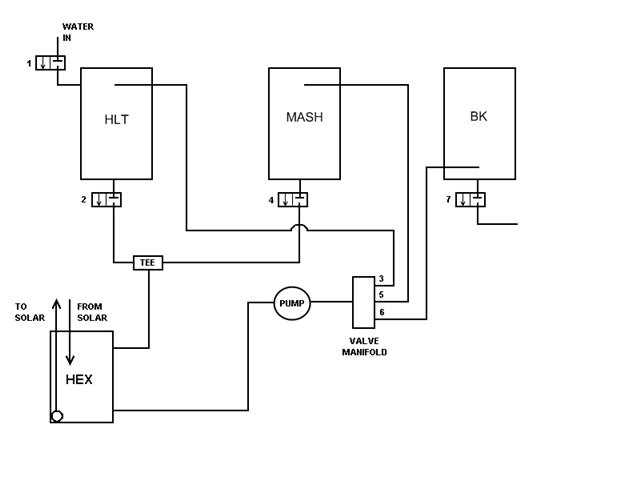

My main concerns are controlling the temp of the heat exchanger and then using that to control the temp of the mash, also I would like to be able to use the heat exchanger to pre-heat the strike water, etc. Any thoughts or suggestions would be great.

In Sept I've gotten the ok from SWMBO that I can build a shed/brew house. The roof of this shed is going to face South so my thought was to put a solar hot water heater on the roof and hook it up to a HERMS rig.

My main concerns are controlling the temp of the heat exchanger and then using that to control the temp of the mash, also I would like to be able to use the heat exchanger to pre-heat the strike water, etc. Any thoughts or suggestions would be great.