kal

Well-Known Member

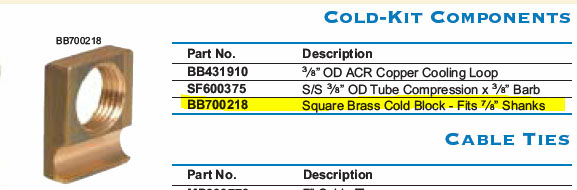

Has anyone ever seen a product that screws onto a standard 7/8" diameter shank that is has a couple of barbed connects so that you can pump cold water or glycol through to keep a shank/tap combo chilled?

Was going to wrap some thin copper pipe around (if I can do that without it breaking), but if an actual product exists, so much the better!

Thanks!

Kal

Was going to wrap some thin copper pipe around (if I can do that without it breaking), but if an actual product exists, so much the better!

Thanks!

Kal