jimconnors

Member

- Joined

- Mar 13, 2008

- Messages

- 17

- Reaction score

- 0

I am starting to look at collecting the pieces for a brew rig. To do that, I need to get a solid plan together, and hopefully that will involve you input - I've seen your rigs and I grovel for your help!

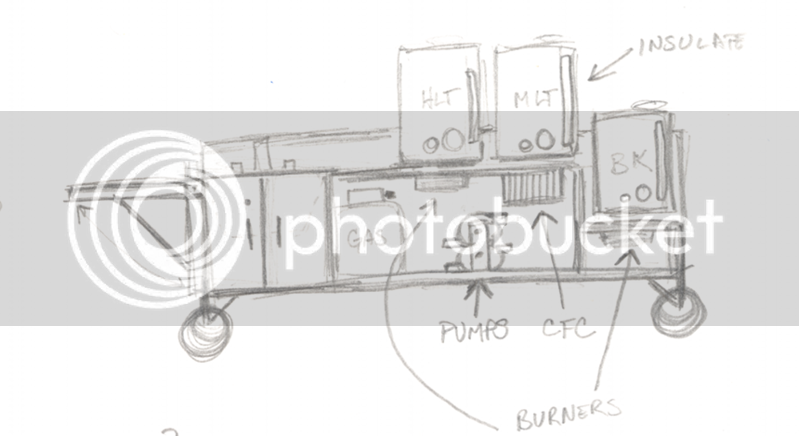

A few night of scribbles, scrap and graphite stains I have an initial rough draft above.

Basic Features (going from left to right):

The plan is to stay with batch sparging and experiment with fly sparging and eventually to make a decision and upgrade to a HERMS or RIMS system if appropriate. I have only done a few AG batches and haven't decided which way to go. Also, I haven't decided on materials - I can weld and have friends that are good welders as well. However I am a wood furniture lover and like to woodwork as well. Really it comes down to cost, maintenance, and portability as I will be brewing on location quite often.

I plan to hook up a garden hose and run water from the back left side, to the sink and to the HLT. Likely I will add a filter just to be sure I don't get any debris from the hose.

I liked Bobby's QD setup and hose (silicone) setup and will follow that path I think. The male threaded end on the kettles & pumps and 90 degree female QDs on the hoses.

Have any of you experienced issues with trapped air when priming the pumps with liquid? I have seen a few designs where a T'd valve is on the out end to allow air purge and then the flow is opened to the target.

Aside from that, I chose not to fire the MLT yet since I only have 2 keggles so far and want to KISS and upgrade as I go and develop my preferences.

So, open the flood gates! What would you do different on your rig? Any and all tips and tricks are totally welcome as I will be coming up with a detailed plan for the build with your input.

Thanks!!!

Jim

A few night of scribbles, scrap and graphite stains I have an initial rough draft above.

Basic Features (going from left to right):

- A fold down desk area for my brew log, calculator, smokes and my homebrew. (hmmm maybe I need to add a cupholder...)

- Basic Sink fed by hose water, cabinet doors enclosure. (storage of cleaners etc in there.)

- Backsplash/Heat shield/Wind shield approximately 5-6 inches higher than the sink clear across to the far end brew kettle.

- Hop and other brew ingredient recessed bins. (between the sink and the HLT.)

- HLT - Keggle, propane fired. Valve, sight-glass, and thermometer.

- MLT - Keggle, not fired. Insulated. Sparge device of some sort on top. Valve, sight-glass, and thermometer.

- Pumps - Two march pumps below.

- CFC - Mounted below the MLT.

- BK - Keggle, propane fired. Valve, sight-glass, and thermometer.

The plan is to stay with batch sparging and experiment with fly sparging and eventually to make a decision and upgrade to a HERMS or RIMS system if appropriate. I have only done a few AG batches and haven't decided which way to go. Also, I haven't decided on materials - I can weld and have friends that are good welders as well. However I am a wood furniture lover and like to woodwork as well. Really it comes down to cost, maintenance, and portability as I will be brewing on location quite often.

I plan to hook up a garden hose and run water from the back left side, to the sink and to the HLT. Likely I will add a filter just to be sure I don't get any debris from the hose.

I liked Bobby's QD setup and hose (silicone) setup and will follow that path I think. The male threaded end on the kettles & pumps and 90 degree female QDs on the hoses.

Have any of you experienced issues with trapped air when priming the pumps with liquid? I have seen a few designs where a T'd valve is on the out end to allow air purge and then the flow is opened to the target.

Aside from that, I chose not to fire the MLT yet since I only have 2 keggles so far and want to KISS and upgrade as I go and develop my preferences.

So, open the flood gates! What would you do different on your rig? Any and all tips and tricks are totally welcome as I will be coming up with a detailed plan for the build with your input.

Thanks!!!

Jim