rangrr4834

Active Member

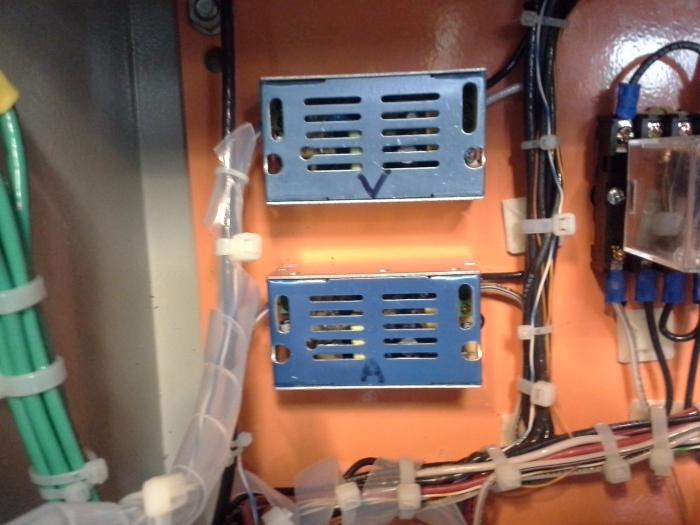

I started working on my control panel recently and I thought I would post pics as I move forward. I have already learned much working on this.

I began to cut the holes for the front. I used different carbon drill bits and a drill press to make the starter holes. I have a friend that does electrical work and he is going to loan me his punch to make the 22mm round cutouts.

I began to cut the holes for the front. I used different carbon drill bits and a drill press to make the starter holes. I have a friend that does electrical work and he is going to loan me his punch to make the 22mm round cutouts.