mrstevenund

Well-Known Member

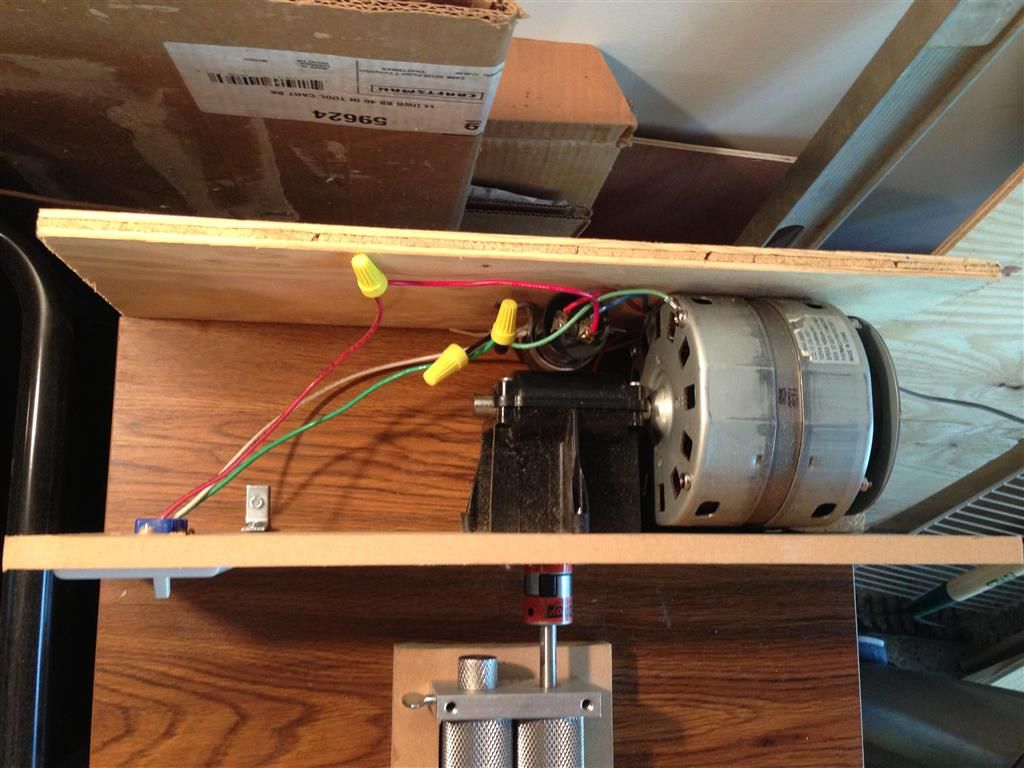

I bought a MM2 two weeks ago and now have the job of building a hopper/stand and motorizing it. I'm not so keen on the idea of a 1725rpm motor with a 12inch pulley on it. I'd prefer something more compact.

I haven't found a whole lot of information on using a garage door opener to power a mill. I found at http://www.surpluscenter.com/item.asp?catname=electric&qty=1&item=5-1677 which has the worm gear assembly to output 110RPM. (Little slower than MM's recommended 150-250 RPM, but I've read slower is better)

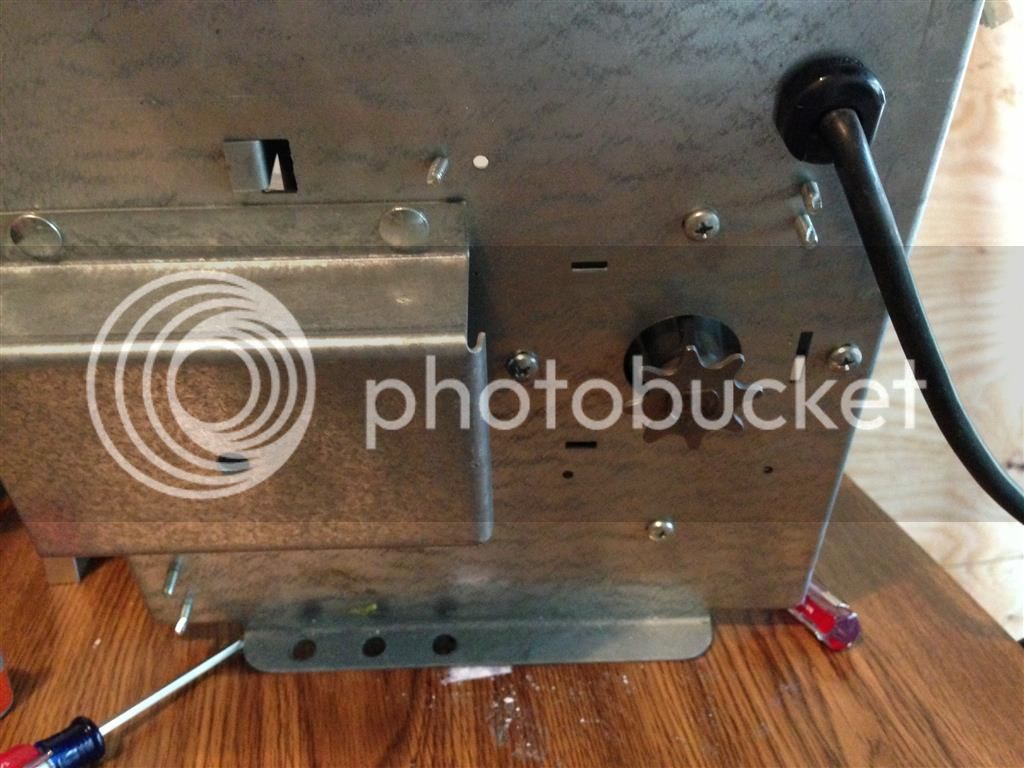

Working under the assumption that the output shaft is on the bottom, my thought was to crease and bend the metal plate 90 degrees up, and bolt this face downward making the shaft horizontal. I haven't decided whether a small sprocket/chain or direct drive would be better, or if this motor would even work. I realize garage door openers are designed for around 5 operations per hour, and milling would be like 5 minutes total (maybe over estimating. I'm only set up for 5G batches)

I haven't found a whole lot of information on using a garage door opener to power a mill. I found at http://www.surpluscenter.com/item.asp?catname=electric&qty=1&item=5-1677 which has the worm gear assembly to output 110RPM. (Little slower than MM's recommended 150-250 RPM, but I've read slower is better)

Working under the assumption that the output shaft is on the bottom, my thought was to crease and bend the metal plate 90 degrees up, and bolt this face downward making the shaft horizontal. I haven't decided whether a small sprocket/chain or direct drive would be better, or if this motor would even work. I realize garage door openers are designed for around 5 operations per hour, and milling would be like 5 minutes total (maybe over estimating. I'm only set up for 5G batches)