You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Brewpub equipment

- Thread starter andy75

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Welcome! You've got a lofty but admirable goal, and I'm sure I speak for a few of us when I say that we're excited for you!

First, where are you? That may help us narrow down your options.

First, where are you? That may help us narrow down your options.

Nwcw2001

Well-Known Member

well you are where I was 2 years ago! now I just need the money!

check out these sites

for great insight and help:

http://www.probrewer.com/

For used equipment:

http://www.nabrewing.com/products.shtml

http://ager-tank-equipment.com/brewing/index.asp

For new equipment:

http://www.jvnw.com/brewing.html

http://www.pbstbeer.com/

And on a personal note, I think you should look to getting, The Brewers Association's Guide to Starting Your Own Brewery.

It has tons of info and helpful numbers.

Good luck with your dream. If you need any pointers let me know!

John

check out these sites

for great insight and help:

http://www.probrewer.com/

For used equipment:

http://www.nabrewing.com/products.shtml

http://ager-tank-equipment.com/brewing/index.asp

For new equipment:

http://www.jvnw.com/brewing.html

http://www.pbstbeer.com/

And on a personal note, I think you should look to getting, The Brewers Association's Guide to Starting Your Own Brewery.

It has tons of info and helpful numbers.

Good luck with your dream. If you need any pointers let me know!

John

Thank you Nwcw2001 for the thoughtful post you put up in response to andy75. I am in the same boat, wondering what it takes to go pro. The links you have provided and the BA Giude book will be a great help to me also. Seems I have found the right place to look for answers. I am happy I registered here.

celticcolorado

Well-Known Member

Best of luck to you..and remember...that all of us at HBT are living vicariously through you. Keep us updated on how things are going.

Budzu

Well-Known Member

I am in the same boat Andy, and I wish you the best of luck! My place is going to be pretty small, and we are going with a 2 bbl system. We are having a 3 vessel (80g,80g,90g) system built by Stout Tanks and Kettles. They can build you a 4 vessel (including conical) 1 bbl for less than 3k.

Our 2 bbl system is quite affordable as well, and will include conveniences like spray balls, butterfly valves, tri-clamp electric element adapters... very very cool toys.

John W. at stout tanks was very helpful and is willing to customize a system to whatever needs you have.

I don't think you can do much better than this for a new, SMALL system.

Our 2 bbl system is quite affordable as well, and will include conveniences like spray balls, butterfly valves, tri-clamp electric element adapters... very very cool toys.

John W. at stout tanks was very helpful and is willing to customize a system to whatever needs you have.

I don't think you can do much better than this for a new, SMALL system.

http://www.gwkent.com/ is another good place

BrewBeemer

Well-Known Member

Budzu,

I must second it with Stout as well John with his quick and straight answers he will work with you. My problem was the high shipping cost of a fermenter from Oregon to Calif, it can be picked up a great savings.

Matt at CHI has been working on importing brewing equipment also but it's been a long time dealing with his supplier like nearing two years from the introduction on HBT.

On larger equipment CHI supplies tanks and equipment for the wineries in the Napa wine area Northern Calif.

I must second it with Stout as well John with his quick and straight answers he will work with you. My problem was the high shipping cost of a fermenter from Oregon to Calif, it can be picked up a great savings.

Matt at CHI has been working on importing brewing equipment also but it's been a long time dealing with his supplier like nearing two years from the introduction on HBT.

On larger equipment CHI supplies tanks and equipment for the wineries in the Napa wine area Northern Calif.

I am in the same boat Andy, and I wish you the best of luck! My place is going to be pretty small, and we are going with a 2 bbl system. We are having a 3 vessel (80g,80g,90g) system built by Stout Tanks and Kettles. They can build you a 4 vessel (including conical) 1 bbl for less than 3k.

Our 2 bbl system is quite affordable as well, and will include conveniences like spray balls, butterfly valves, tri-clamp electric element adapters... very very cool toys.

John W. at stout tanks was very helpful and is willing to customize a system to whatever needs you have.

I don't think you can do much better than this for a new, SMALL system.

could you give me a ball park of what that system is going to run you before shipping?

I'm also working on my business plan for a brewery. Would love to go a lttle larger, more like 7 to 15 bbl but I know I wont have the funds for that.

I am in the same boat Andy, and I wish you the best of luck! My place is going to be pretty small, and we are going with a 2 bbl system. We are having a 3 vessel (80g,80g,90g) system built by Stout Tanks and Kettles. They can build you a 4 vessel (including conical) 1 bbl for less than 3k.

Our 2 bbl system is quite affordable as well, and will include conveniences like spray balls, butterfly valves, tri-clamp electric element adapters... very very cool toys.

John W. at stout tanks was very helpful and is willing to customize a system to whatever needs you have.

I don't think you can do much better than this for a new, SMALL system.

Have you received the Stout Tank setup? How is it?

Budzu

Well-Known Member

Have you received the Stout Tank setup? How is it?

Yep, just got it on Tuesday actually. Its quite handsome> Have to still order all the fittings I need and replumb the room a bit before I get it rolling. Haven't pictured the fermenter, but also have the 80g conical. The boil kettle has a bottom drain for both the center and the side, with a slight cone to the bottom of the tank. Going to be great for managing trub and hops. Everything has sprayballs and bottom drains which I LOVE. Excited to fire it up. I posted these in another thread:

NICE! Is that a steam/electric/burner system?

Budzu

Well-Known Member

Not steam, but direct electric heat. There are 2 tri-clamp adapters on each the BK and HLT which accept standard heating elements.

Not steam, but direct electric heat. There are 2 tri-clamp adapters on each the BK and HLT which accept standard heating elements.

What kind of heating times are you expecting? Which elements are you going to use? How long did it take to receive your stuff?

Budzu

Well-Known Member

Not sure how the heating times will work, I've been brewing 1 bbl batches with 11,000 watt. Heating times have been very good with that, so I'll be using my sticks along with the kettle mounted elements to make 20,500 watt of heating power available. The design of the kettle was only for the two elements, but I believe it will need more than 11-12kw to boil. I could go as high as 24kw if needed.

It took about 3 months since we put in the order. They were delivered by freight from Portland, arrived via tractor trailor.

It took about 3 months since we put in the order. They were delivered by freight from Portland, arrived via tractor trailor.

BrewBeemer

Well-Known Member

Those tanks look to pretty too use nice score.

Your going into a commercial building or single phase heating

as you'll need a 125 amp breaker for your 24KW of heating?

Your going into a commercial building or single phase heating

as you'll need a 125 amp breaker for your 24KW of heating?

Budzu

Well-Known Member

Those tanks look to pretty to use nice score.

Your going into a commercial building or single phase heating

as you'll need a 125 amp breaker for your 24KW of heating?

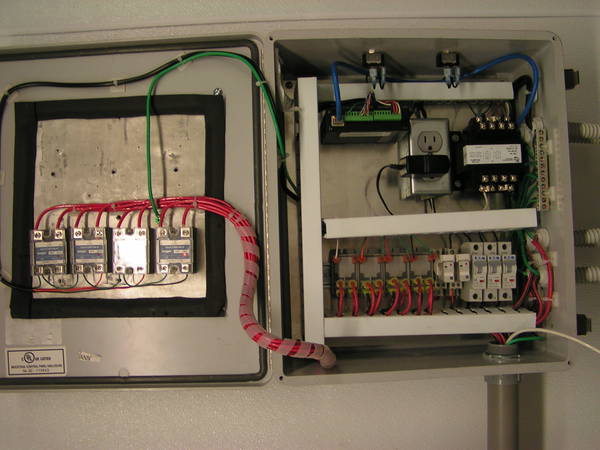

Yes I've already setup the control panel. those 4 relays are fed through the conduit from one of our mains, from 4 seperate 30amp gfi's and a 20. It is all hard wired through flexible conduit. This pic is actually sideways... the lid lifts up. There is a 12" square heatsink on the door that was too heavy to mount the door horizontal

Curious as to how its going with the new system. I've also been looking into their 2 or 3 BBl system, but would be nice to here some feedback before ordering. Supposedly there will be one installed in my neck of the woods shortly (upstate NY) that I'll check out in the next few months.

I'm assuming you're brewing by now and if so could you post some more pics of the setup also comment on what type of pumps, chillers, other equipment you're using. Also any criticism of the design, quality, thickness of kettle, etc..?

Thanks,

Ryan

I'm assuming you're brewing by now and if so could you post some more pics of the setup also comment on what type of pumps, chillers, other equipment you're using. Also any criticism of the design, quality, thickness of kettle, etc..?

Thanks,

Ryan

Budzu

Well-Known Member

Yeah I've brewed on it a few times. Actually tonight I am brewing on it for the 3rd time. I will attempt to take and post some pictures this evening of it in action.

I have no complaints about the quality or ruggedness of the tanks. There is only one design complaint.

The Boil Kettle (which includes a center bottom drain and a side bottom drain) has a slightly coned bottom, which makes whirlpooling work wonderfully. The MT and HLT both have completely flat bottoms. The only problem with that is the clean-in-place ability. While cleaning the MT, it is difficult to get all the grain bits to rinse away out the bottom outlet. This is minor and there's no problem leaving some bits in there, but if I was able to go back and re-specify, I would've requested that all 3 tanks have coned bottoms.

Also had to request one extra butterfly valve, which wasn't included for the BK's tangential inlet port. The way I brew I needed to be able to disconnect/connect that hose while the BK is full.

For heating, it is working well so far up to a 60 gallon boil volume using 11,500 watts of heating power. I was getting about 7.5% boiloff, which I thought seemed low, but the boil is quite strong and the beers don't have DMS that I can perceive, so its fine.

The pump I use is March's new Nano brewery pump (this thing is just awesome, and transfers almost 20 gpm with a 3/4" silicone suction hose and 1/2" discharge hose). This pump is also used for cleaning kegs in place with Sabco's wash/fill coupler. During mashing and sparging, I also pump the water with a normal March 809.

For chilling I use dudadiesel's 50 plate 3/4" port chiller. I do a single pass chill, routing my wort through a long silicone hose from the chiller through the wall into my fermentation room. It typically comes out at about 58-60 degrees, and the fermentation room is held at 62-64 with a 9000btu AC. There are 5 85 gallon plastic conicals, and one 80 gallon stainless conical from Stout.

All beer is kegged in 1/2 barrels (and a corny for take home cuz god knows I have no time to brew at home now sadly), then rolled out into our walk-in cooler. In there I have set up a long-draw system which uses only CO2 to push from there (outside) under our concrete foundation 35 feet to the 8 tap tower on the bar. I use a micromatic glycol power pack chiller to chill those lines and the taps.

I just finished setting up a motorized Monster Mill MM3-2.0. It uses a 1/2 hp single phase motor with belt and pulleys. I'll try to include all this in the pics tonight.

I have no complaints about the quality or ruggedness of the tanks. There is only one design complaint.

The Boil Kettle (which includes a center bottom drain and a side bottom drain) has a slightly coned bottom, which makes whirlpooling work wonderfully. The MT and HLT both have completely flat bottoms. The only problem with that is the clean-in-place ability. While cleaning the MT, it is difficult to get all the grain bits to rinse away out the bottom outlet. This is minor and there's no problem leaving some bits in there, but if I was able to go back and re-specify, I would've requested that all 3 tanks have coned bottoms.

Also had to request one extra butterfly valve, which wasn't included for the BK's tangential inlet port. The way I brew I needed to be able to disconnect/connect that hose while the BK is full.

For heating, it is working well so far up to a 60 gallon boil volume using 11,500 watts of heating power. I was getting about 7.5% boiloff, which I thought seemed low, but the boil is quite strong and the beers don't have DMS that I can perceive, so its fine.

The pump I use is March's new Nano brewery pump (this thing is just awesome, and transfers almost 20 gpm with a 3/4" silicone suction hose and 1/2" discharge hose). This pump is also used for cleaning kegs in place with Sabco's wash/fill coupler. During mashing and sparging, I also pump the water with a normal March 809.

For chilling I use dudadiesel's 50 plate 3/4" port chiller. I do a single pass chill, routing my wort through a long silicone hose from the chiller through the wall into my fermentation room. It typically comes out at about 58-60 degrees, and the fermentation room is held at 62-64 with a 9000btu AC. There are 5 85 gallon plastic conicals, and one 80 gallon stainless conical from Stout.

All beer is kegged in 1/2 barrels (and a corny for take home cuz god knows I have no time to brew at home now sadly), then rolled out into our walk-in cooler. In there I have set up a long-draw system which uses only CO2 to push from there (outside) under our concrete foundation 35 feet to the 8 tap tower on the bar. I use a micromatic glycol power pack chiller to chill those lines and the taps.

I just finished setting up a motorized Monster Mill MM3-2.0. It uses a 1/2 hp single phase motor with belt and pulleys. I'll try to include all this in the pics tonight.

newski

Member

+1 on the detailed info. good luck with the brew tonight. subscribed

That all sounds just like what I have planned only I need to go at least 3bbl. Can't wait to see the pics.

Trouble-Brewing

Well-Known Member

x2 ^^^^

How do you like the plastic conicals? Any specific reason you didn't just go all plastic?

How do you like the plastic conicals? Any specific reason you didn't just go all plastic?

Budzu

Well-Known Member

Well got really busy while brewing and didn't photo anything... I'm having issues figuring out my numbers. My boil-off volume loss is not matching my gravity readings. But I got 40 gallons on my IPA into a fermenter and gave it some yeast from my pale ale right next to it.

I really like the plastic conicals. I drilled out one of the lids (which are about 16" in diameter and screw-in) to install a sprayball I got from St. Pats. Put a 1/3 hp sump pump in a bucket below the 1" bottom drain. Using 3/4" hose the pump will really drive that spray ball and clean the entire conical in minutes. There is no residual plastic taste that anyone can perceive, and these beers all taste better than what I've done at home.

These conicals cannot be pressurized, so I had someone cut the legs and weld on some extensions, in order to fit a keg underneath the cone.

I put the side port at about the 3 gallon mark, which is halfway up the cone. I think it was too high, it should be maybe 1/3 up the cone. I just leave more beer in the bottom than yeast this way. For the remaining 3 undrilled conicals I will place it quite lower.

The plastic conicals are kind of a pad for our startup costs I would've wanted all SS, but this saved us alot of money. The stainless one I may place in our walk-in, or fit with a glycol jacket to lager in the ferm. room. The plan is to replace them as we are able with stainless.

I would've wanted all SS, but this saved us alot of money. The stainless one I may place in our walk-in, or fit with a glycol jacket to lager in the ferm. room. The plan is to replace them as we are able with stainless.

This was before I discovered those cool stainless cooling plates super-cheap that I could easily install in the lids of the plastic conicals

So I'll probably end up keeping these plastic ones for a good while.

Brewing again on Thursday, will be testing the full volume capacity of these things with a 75gallon boil volume, over 100lb of grain, and 1.5lb of hops.

Here are some pics of the conicals and the beginnings of some krausen:

I really like the plastic conicals. I drilled out one of the lids (which are about 16" in diameter and screw-in) to install a sprayball I got from St. Pats. Put a 1/3 hp sump pump in a bucket below the 1" bottom drain. Using 3/4" hose the pump will really drive that spray ball and clean the entire conical in minutes. There is no residual plastic taste that anyone can perceive, and these beers all taste better than what I've done at home.

These conicals cannot be pressurized, so I had someone cut the legs and weld on some extensions, in order to fit a keg underneath the cone.

I put the side port at about the 3 gallon mark, which is halfway up the cone. I think it was too high, it should be maybe 1/3 up the cone. I just leave more beer in the bottom than yeast this way. For the remaining 3 undrilled conicals I will place it quite lower.

The plastic conicals are kind of a pad for our startup costs

This was before I discovered those cool stainless cooling plates super-cheap that I could easily install in the lids of the plastic conicals

So I'll probably end up keeping these plastic ones for a good while.

Brewing again on Thursday, will be testing the full volume capacity of these things with a 75gallon boil volume, over 100lb of grain, and 1.5lb of hops.

Here are some pics of the conicals and the beginnings of some krausen:

Trouble-Brewing

Well-Known Member

Sweet, that sounds like a really cool setup. Are you just going to fill kegs with gravity then have a bunch of keg couplers hooked only to gas in your cold box for carbonation? That plate chiller idea just made my plan a lot simpler. I was think of putting the conicals on wheels then rolling them into the cold box to lager. I wonder how cold you could get them with a little chest freezer glycol setup? If you feel like taking more pictures I would enjoy seeing the rest of your brewery.

Budzu

Well-Known Member

Yes, i gravity fill them with a wash/fill coupler, then roll them outside and put them on couplers with sample taps, and force carb.

I'm hoping to get a chest-freezer chiller going as well, unless we find another good deal on a commercial unit. The one we have for our taps has a 5 gallon bath and cost us less than 1k.

I'd think it would work great for chilling down to 50 or so with those 300$ plates from st pats, but it would be pretty inefficient I would think to go towards the 30's. I could be wrong... the plastic walls are verrrry thick and might insulate enough.. but that's a pretty big temp difference.

But for now all my cold conditioning is done in keg, in the walk-in. I just don't move the kegs once they are in there.

I'm hoping to get a chest-freezer chiller going as well, unless we find another good deal on a commercial unit. The one we have for our taps has a 5 gallon bath and cost us less than 1k.

I'd think it would work great for chilling down to 50 or so with those 300$ plates from st pats, but it would be pretty inefficient I would think to go towards the 30's. I could be wrong... the plastic walls are verrrry thick and might insulate enough.. but that's a pretty big temp difference.

But for now all my cold conditioning is done in keg, in the walk-in. I just don't move the kegs once they are in there.

I've honetly never seen plate chillers for inside of conicals! That's a great idea and probably easier than glycol(?). Do you have a link for those? Great set-up by the way!

Trouble-Brewing

Well-Known Member

You would probably run glycol through the chiller, just a hell of a lot cheaper then a jacketed stainless fermenter. The plates are from here http://www.stpats.com/index.htm

Budzu

Well-Known Member

Just to clarify, I don't yet own any of those cooling plates. It is just the better option I discovered while trying to think of a glycol jacket strategy. Jacketing these plastics wouldn't work well at all because of the legs in the way, plus the thickness of the plastic.

wildwest450

Well-Known Member

- Joined

- Dec 27, 2007

- Messages

- 8,978

- Reaction score

- 191

I'm waiting for my invitation to come and help on a batch. That setup looks amazing.

_

_

Fantastic setup...I'm not far from Chatty...what's your brewery's name?

I found those plate chillers a few weeks ago while looking for tri-clamp stuff. They look cool and I think it would work well for a 1-3 bbl fermenter. Would love to know how they work if you ever do get them.

wedge421

Well-Known Member

Did the system from Stouts include the RIMS tube and everything? What exactly did you have to add? Looks like a great setup

Budzu

Well-Known Member

I'm waiting for my invitation to come and help on a batch. That setup looks amazing.

Tell me when is a good time! I brew 2-3 times a week. We are finishing up the ingredients next week for all our test batches. TTB approval is coming within the week. Then we must put together a large ingredient order from Brewer's Supply Group.

Fantastic setup...I'm not far from Chatty...what's your brewery's name?

McHale's Brewhouse and Pub, its between Hixson and Red Bank, just north of Chatt.

Did the system from Stouts include the RIMS tube and everything? What exactly did you have to add? Looks like a great setup

It did not include a RIMS tube, but the HLT has the "RIMS" coil option, which is a stainless HERMS coil actually. I do a constant recirc through it, and it raises the mash nicely to mashout, as long as you submerge the entire coil which is high up in the HLT. I must have at least 65 gallons in the HLT to utilize the coil effectively, no matter my boil volume.

scwhoa!!! that thing looks awesome!!! if im ever in TN ill be sure to let you know and make a visit to the brewpub

Wortimer75

Active Member

Ran across this thread and its been about 6 months, I am curious how the Stout tanks are performing? Would you buy again?

Congrats on the brewpub! Are you still using the plastic conicals?

Congrats on the brewpub! Are you still using the plastic conicals?

Endurancefuel

New Member

Budzu, Congratulations on taking the leap. I'm in the planning stages of a brewpub, and this is one of the few threads I have read that was actually encouraging! If anyone knows of some other successful brewpub threads, please share.

I'm also curious how your setup is going now that it has been operational for a while.

I'm also curious how your setup is going now that it has been operational for a while.

Similar threads

- Replies

- 3

- Views

- 668

- Replies

- 0

- Views

- 294

Latest posts

-

Best way to connect blichmann beer gun to a 1.5" TC unitank racking port.

- Latest: iandanielursino

-

-

-

-

-

-