crazyworld

Well-Known Member

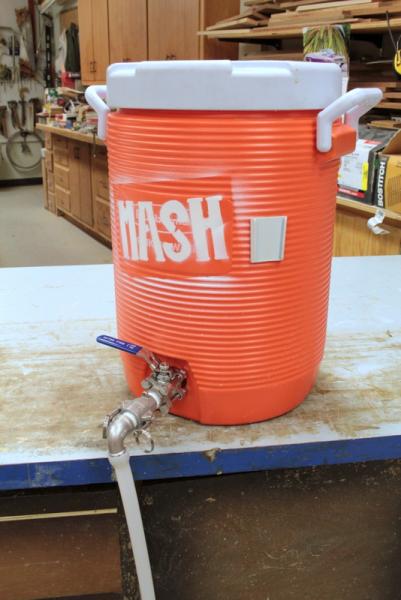

Hey guys. Got another one for you. Check out my latest project.

Not only did I build a KILLER mash tun, my friend and I shot a video on how to make one yourself.

Video:

Description:

In this video I show you how to build your own beverage cooler mash/lauter tun for homebrewing your own beer. You can use any type of cooler for this project, but your hardware will vary.

I chose to do a 5 gallon mash tun because I had one lying around but this is really as small as you would want to go for a 5 gallon batch of beer. Most people choose something in the 20qt (5 gal) to 50qt (12.5 gal) range. The larger end will accommodate larger gravity beers and most 10 gallon batches.

My rig, besides the mash tun itself, uses all stainless steel components as well as all silicone gaskets and tubing. DO NOT use conduit locknuts, parts labeled only as "steel," or anything galvanized. These items are plated in zinc which will readily dissolve in the (slightly) acidic wort and can cause toxicity. Brass is generally regarded as fine for the laybrewer although the biggest concern here is the lead content. Look for "lead-free" brass which will have no more than 0.25% lead. Otherwise, soak all brass parts in two parts of white vinegar and one part of hydrogen peroxide for no more than 5 minutes to remove surface lead. If you're still concerned, just go stainless. Yes, stainless steel parts are expensive, but they will last a lifetime!

My fittings are 1/2" NPT while 3/8" are probably more common as they are cheaper and can be found locally more easily. Understand that the hardware requirements will vary and your options for assembly are endless. I highly suggest you plan your build before you go shopping and plan on making a run to the hardware store when things don't work out. When I went to order my parts, they were out of FNPT hose barbs so I was forced to buy a coupler and use a MNPT hose barb instead. It's common with a 2 piece ball valve to need to shim it away from the cooler with another locknut or washers if your handle cannot fully close. These can be made of whatever material you wish as they will not touch the liquid.

Be sure to use an NPS (straight threaded) locknut as I did if you wish to thread it all the way onto the pipe nipple (heads up, very few places will have them). Also, you can save here by not using a barb on the inside and putting the braid directly over the inside of the nipple. However, I chose to use the barb to remove the braid for easy removal for cleaning and drying (no need to remove the hose clamp). The barb was only $4 (although I did have to spend another $3.50 for the coupler in my scenario) so I'm not losing sleep over it.

Be sure to test for leaks when I recommend you do as you'll only waste time later if you run into one. If you do encounter a leak, make sure you've wrapped the half of the pipe nipple that threads into the ball valve. I also wrapped the center of the nipple to ensure a smooth, tight surface for the gasket to hug up against. If you don't have a flat surface for the gasket to sit, pack your threads with Teflon tape until you do. Lastly, make sure you're putting enough compression on the gasket. I found it's unnecessary to bend the washer to conform it to the side of the cooler so long as your gasket is thick enough and you have good compression on it.

I used an awl to help get the silicone tubing on the elbow. This stuff is thick so don't worry too much about gouging it. Once it's on there, I don't plan on taking mine off.

And because I know you guys would go nuts if I didn't post it...

Supplies and prices:

All metal parts are 316 stainless steel and ½” NPT unless specified otherwise. All prices include NYS tax where applicable. All quantities are (1) unless otherwise specified.

14.95 Ball valve – 3 piece

3.50 Coupler

4.00 5/8” outlet hose barb

4.75 90 degree street elbow

3.92 “F” camlock adapter

5.62 “B” camlock coupler

7.17 3ft – ½” ID x ¾” OD silicone tubing

2.49 1 ½” pipe nipple (304 SS)

1.99 ¾” ID x 1 ½” OD silicone gasket

3.75 NPS locknut (304 SS)

1.99 15/16” ID x 1 ½” OD washer (304 SS)

9.65 ¾” female NPT x 18” SS water heater connector

1.95 9/16” x 1 ¼” SS hose clamp

10.00 5 gallon Rubbermaid beverage cooler (used)

xx.xx Teflon tape & spray paint

$74.73 TOTAL

The way I look at it, I have an AWESOME mash tun that I can upgrade whenever I want and take the parts with me. Plus, those parts will last me a LIFETIME of brewing.

Thoughts? Comments?

Nick

Not only did I build a KILLER mash tun, my friend and I shot a video on how to make one yourself.

Video:

Description:

In this video I show you how to build your own beverage cooler mash/lauter tun for homebrewing your own beer. You can use any type of cooler for this project, but your hardware will vary.

I chose to do a 5 gallon mash tun because I had one lying around but this is really as small as you would want to go for a 5 gallon batch of beer. Most people choose something in the 20qt (5 gal) to 50qt (12.5 gal) range. The larger end will accommodate larger gravity beers and most 10 gallon batches.

My rig, besides the mash tun itself, uses all stainless steel components as well as all silicone gaskets and tubing. DO NOT use conduit locknuts, parts labeled only as "steel," or anything galvanized. These items are plated in zinc which will readily dissolve in the (slightly) acidic wort and can cause toxicity. Brass is generally regarded as fine for the laybrewer although the biggest concern here is the lead content. Look for "lead-free" brass which will have no more than 0.25% lead. Otherwise, soak all brass parts in two parts of white vinegar and one part of hydrogen peroxide for no more than 5 minutes to remove surface lead. If you're still concerned, just go stainless. Yes, stainless steel parts are expensive, but they will last a lifetime!

My fittings are 1/2" NPT while 3/8" are probably more common as they are cheaper and can be found locally more easily. Understand that the hardware requirements will vary and your options for assembly are endless. I highly suggest you plan your build before you go shopping and plan on making a run to the hardware store when things don't work out. When I went to order my parts, they were out of FNPT hose barbs so I was forced to buy a coupler and use a MNPT hose barb instead. It's common with a 2 piece ball valve to need to shim it away from the cooler with another locknut or washers if your handle cannot fully close. These can be made of whatever material you wish as they will not touch the liquid.

Be sure to use an NPS (straight threaded) locknut as I did if you wish to thread it all the way onto the pipe nipple (heads up, very few places will have them). Also, you can save here by not using a barb on the inside and putting the braid directly over the inside of the nipple. However, I chose to use the barb to remove the braid for easy removal for cleaning and drying (no need to remove the hose clamp). The barb was only $4 (although I did have to spend another $3.50 for the coupler in my scenario) so I'm not losing sleep over it.

Be sure to test for leaks when I recommend you do as you'll only waste time later if you run into one. If you do encounter a leak, make sure you've wrapped the half of the pipe nipple that threads into the ball valve. I also wrapped the center of the nipple to ensure a smooth, tight surface for the gasket to hug up against. If you don't have a flat surface for the gasket to sit, pack your threads with Teflon tape until you do. Lastly, make sure you're putting enough compression on the gasket. I found it's unnecessary to bend the washer to conform it to the side of the cooler so long as your gasket is thick enough and you have good compression on it.

I used an awl to help get the silicone tubing on the elbow. This stuff is thick so don't worry too much about gouging it. Once it's on there, I don't plan on taking mine off.

And because I know you guys would go nuts if I didn't post it...

Supplies and prices:

All metal parts are 316 stainless steel and ½” NPT unless specified otherwise. All prices include NYS tax where applicable. All quantities are (1) unless otherwise specified.

14.95 Ball valve – 3 piece

3.50 Coupler

4.00 5/8” outlet hose barb

4.75 90 degree street elbow

3.92 “F” camlock adapter

5.62 “B” camlock coupler

7.17 3ft – ½” ID x ¾” OD silicone tubing

2.49 1 ½” pipe nipple (304 SS)

1.99 ¾” ID x 1 ½” OD silicone gasket

3.75 NPS locknut (304 SS)

1.99 15/16” ID x 1 ½” OD washer (304 SS)

9.65 ¾” female NPT x 18” SS water heater connector

1.95 9/16” x 1 ¼” SS hose clamp

10.00 5 gallon Rubbermaid beverage cooler (used)

xx.xx Teflon tape & spray paint

$74.73 TOTAL

The way I look at it, I have an AWESOME mash tun that I can upgrade whenever I want and take the parts with me. Plus, those parts will last me a LIFETIME of brewing.

Thoughts? Comments?

Nick

Last edited by a moderator:

sorry for the hijack!

sorry for the hijack!