awarner322

Well-Known Member

Hey guys, figured I would start a thread about my electric brew stand build. I have used bits and pieces of ideas from a lot of different threads. The information on here is incredible.

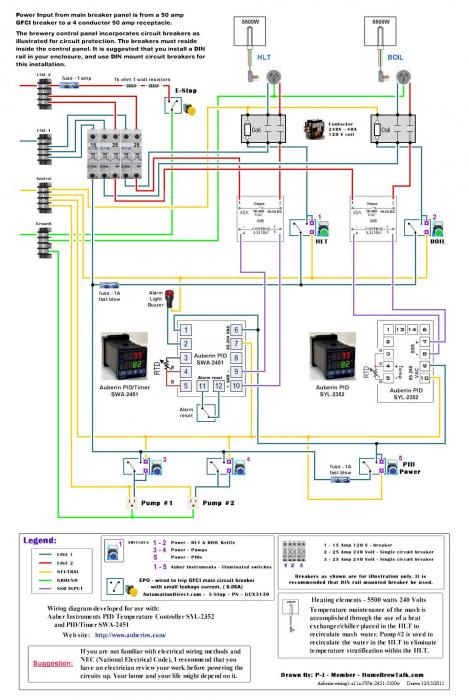

As far as my build...It is/will be a 50a 2 PID system that utilizes 2 pumps and 2 5500watt elements. I used the print posted below that PJ designed (thank you very much...if you read this).

Right now I have the control panel done.

I am making the hot water heater elements, following kals design on his website (thank you very much...if you read this).

I still have a lot of things to finish up...and I hope I can solicit some advice/opinion as I move along.

As far as my build...It is/will be a 50a 2 PID system that utilizes 2 pumps and 2 5500watt elements. I used the print posted below that PJ designed (thank you very much...if you read this).

Right now I have the control panel done.

I am making the hot water heater elements, following kals design on his website (thank you very much...if you read this).

I still have a lot of things to finish up...and I hope I can solicit some advice/opinion as I move along.