Hi Jeff and All,

Finished my version not long ago after starting with collecting and

ordering parts over a year ago after seeing the BYO article.

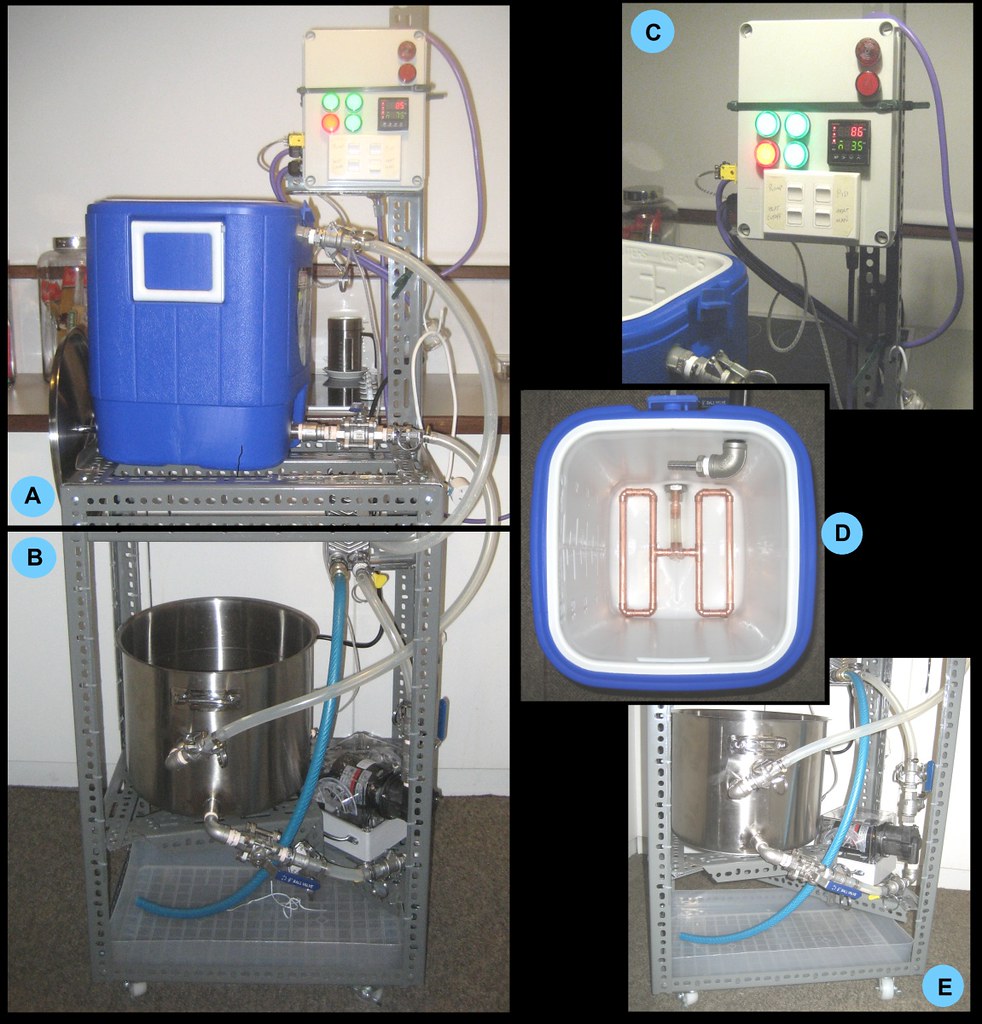

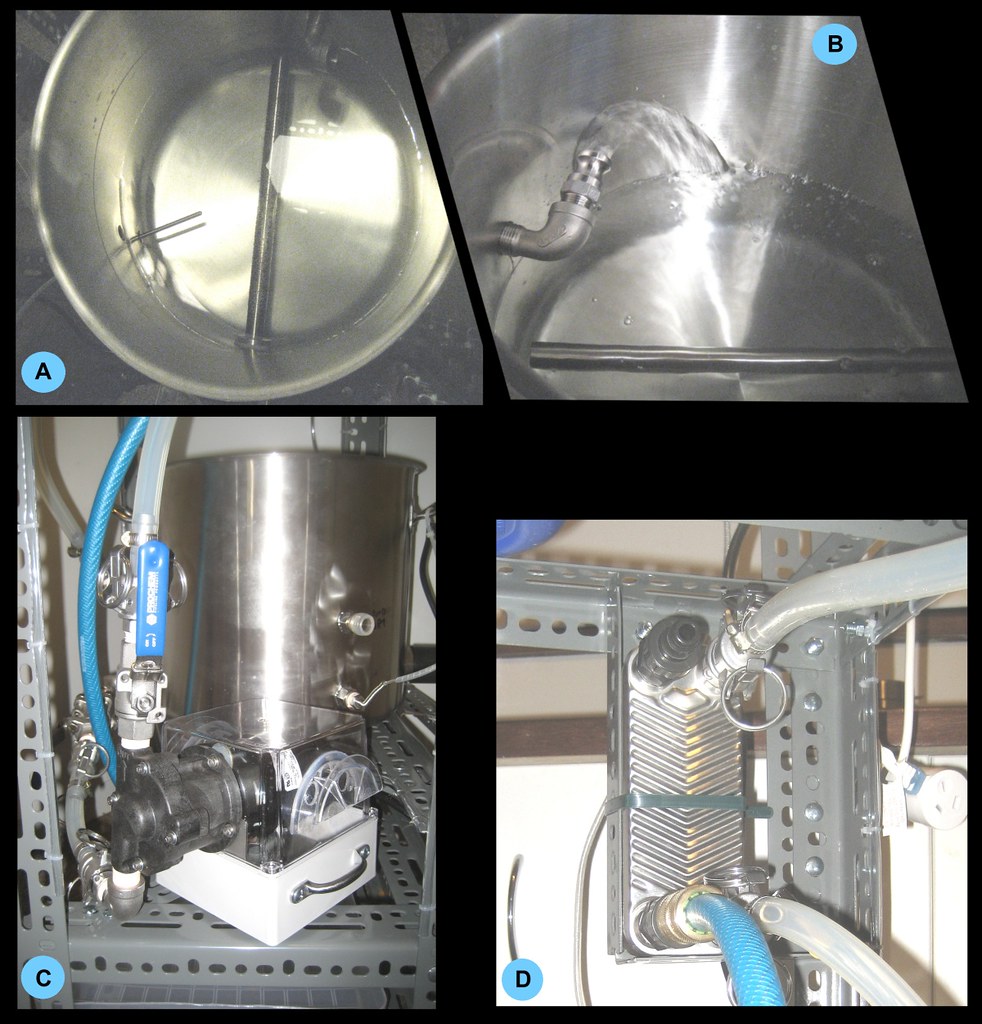

The major difference in my version is use of a plate chiller instead

of an IC. I have a fairly detailed build log in

THIS article for anyone

interested (has heaps more photos - though you have to be a member

of

www.aussiehomebrewer.com in order to access the article).

Have lots of questions needing answers to of course and still in the

stage of learning how to use my system - have done two brews on

it so far and both really used a kind of batch sparging rather than

recirculation.

To address the efficiency issues with a CRDFM system, I'm playing

with draining off a few quarts of the really high gravity first runnings

before recirculating the sparge (the first runnings get added to the

boil when sparging is done). The idea is that recirculating with lower

gravity runnings to sparge would draw out more sugars - would be

good if I can get this technique to work.

Cheers,

Tom.

Cheers

Cheers