- Joined

- Dec 21, 2011

- Messages

- 277

- Reaction score

- 38

After many requests, I finally have enough time to do a write-up on this.

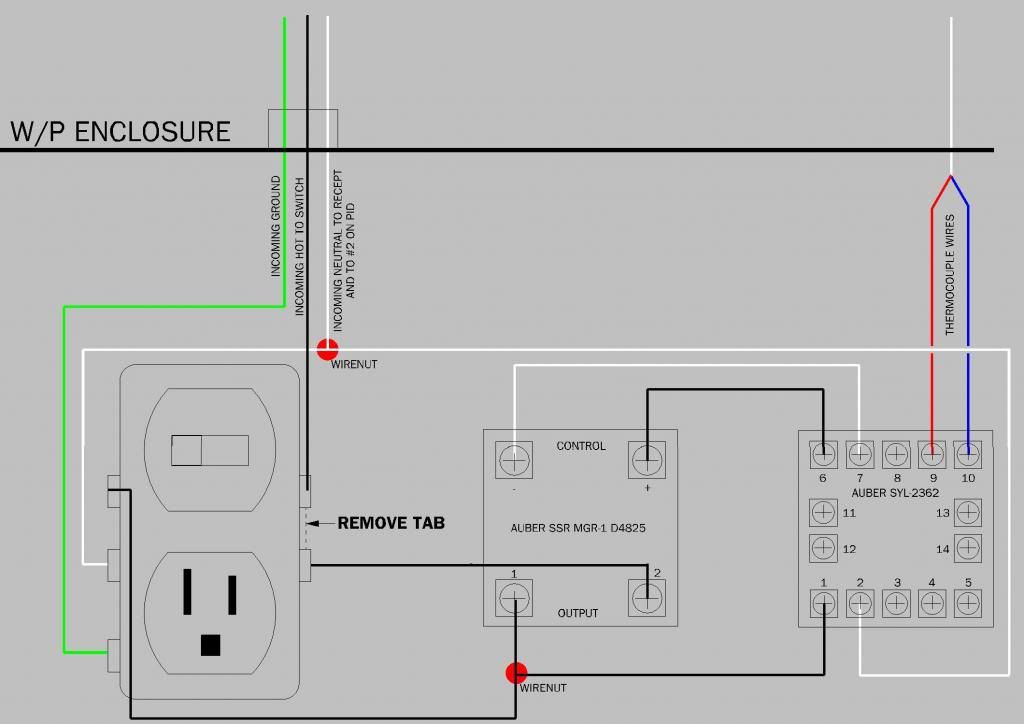

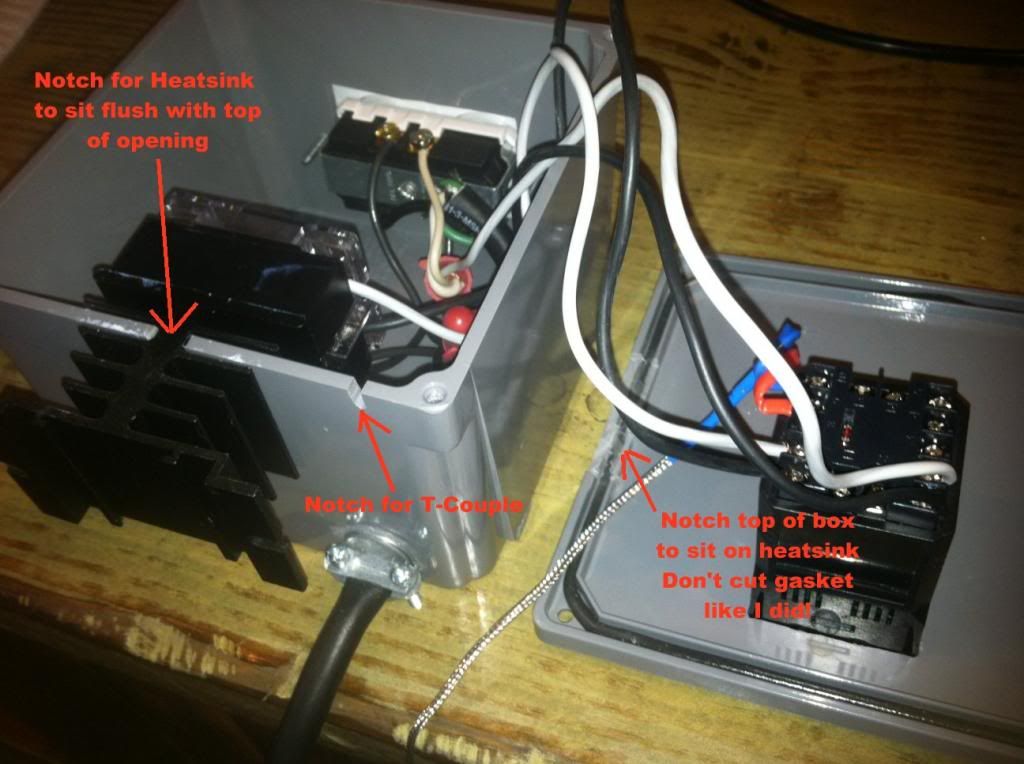

It is my single element, 110v PID controller that I use on my eBIAB setup.

Credit goes to jkarp because I made mine from his original Countertop Brutus 20 Thread.

Parts needed:

Enclosure:

(1) 6x6x4 WP Box. (I am linking to Amazon for reference, I think they are cheaper at HD, Lowes, etc)

http://www.amazon.com/Carlon-E989N-CAR-Junction-Box/dp/B0037MZW1A/ref=sr_1_2?ie=UTF8&qid=1357739799&sr=8-2&keywords=6x6x4+weatherproof+box

Combo Switch/Receptacle and Cover:

http://www.amazon.com/Leviton-109-05225-WSP-Combo-Switch-Receptacle/dp/B00004YUMX/ref=sr_1_1?s=hi&ie=UTF8&qid=1357739869&sr=1-1&keywords=switch+receptacle

2 to 3 feet bulk 12awg wire (hot, neutral, and ground)

http://www.amazon.com/dp/B002G9TNFG/?tag=skimlinks_replacement-20

Replacement extension cord end

http://www.amazon.com/Coleman-Cable-05984-Replacement-Yellow/dp/B000FPANE8/ref=sr_1_1?s=hi&ie=UTF8&qid=1357740128&sr=1-1&keywords=replacement+extension+cord+end

Note. You can also simply buy a 12awg cord, and cut it to length. I was able to buy an end and 3' or wire cheaper than a complete cord, that is why I told you of either option.

1/2" Romex connector

http://www.amazon.com/Romex%C2%AE-Connector-1-2-in/dp/B0003S2MEQ/ref=sr_1_1?s=hi&ie=UTF8&qid=1357740244&sr=1-1&keywords=romex+connector

And you will need 2 wire nuts.

From www.auberins.com:

PID Controller SYL-2362

http://www.auberins.com/index.php?main_page=product_info&cPath=1&products_id=106

Solid State Relay MGR-1 D4825

http://www.auberins.com/index.php?main_page=product_info&cPath=2_30&products_id=9

Heat Sink HS25

http://www.auberins.com/index.php?main_page=product_info&cPath=2_30&products_id=45

K Type Thermocouple

http://www.auberins.com/index.php?main_page=product_info&cPath=20_3&products_id=2

That's it. Build pictures continued in next post.

It is my single element, 110v PID controller that I use on my eBIAB setup.

Credit goes to jkarp because I made mine from his original Countertop Brutus 20 Thread.

Parts needed:

Enclosure:

(1) 6x6x4 WP Box. (I am linking to Amazon for reference, I think they are cheaper at HD, Lowes, etc)

http://www.amazon.com/Carlon-E989N-CAR-Junction-Box/dp/B0037MZW1A/ref=sr_1_2?ie=UTF8&qid=1357739799&sr=8-2&keywords=6x6x4+weatherproof+box

Combo Switch/Receptacle and Cover:

http://www.amazon.com/Leviton-109-05225-WSP-Combo-Switch-Receptacle/dp/B00004YUMX/ref=sr_1_1?s=hi&ie=UTF8&qid=1357739869&sr=1-1&keywords=switch+receptacle

2 to 3 feet bulk 12awg wire (hot, neutral, and ground)

http://www.amazon.com/dp/B002G9TNFG/?tag=skimlinks_replacement-20

Replacement extension cord end

http://www.amazon.com/Coleman-Cable-05984-Replacement-Yellow/dp/B000FPANE8/ref=sr_1_1?s=hi&ie=UTF8&qid=1357740128&sr=1-1&keywords=replacement+extension+cord+end

Note. You can also simply buy a 12awg cord, and cut it to length. I was able to buy an end and 3' or wire cheaper than a complete cord, that is why I told you of either option.

1/2" Romex connector

http://www.amazon.com/Romex%C2%AE-Connector-1-2-in/dp/B0003S2MEQ/ref=sr_1_1?s=hi&ie=UTF8&qid=1357740244&sr=1-1&keywords=romex+connector

And you will need 2 wire nuts.

From www.auberins.com:

PID Controller SYL-2362

http://www.auberins.com/index.php?main_page=product_info&cPath=1&products_id=106

Solid State Relay MGR-1 D4825

http://www.auberins.com/index.php?main_page=product_info&cPath=2_30&products_id=9

Heat Sink HS25

http://www.auberins.com/index.php?main_page=product_info&cPath=2_30&products_id=45

K Type Thermocouple

http://www.auberins.com/index.php?main_page=product_info&cPath=20_3&products_id=2

That's it. Build pictures continued in next post.

Last edited by a moderator: