akthor

Well-Known Member

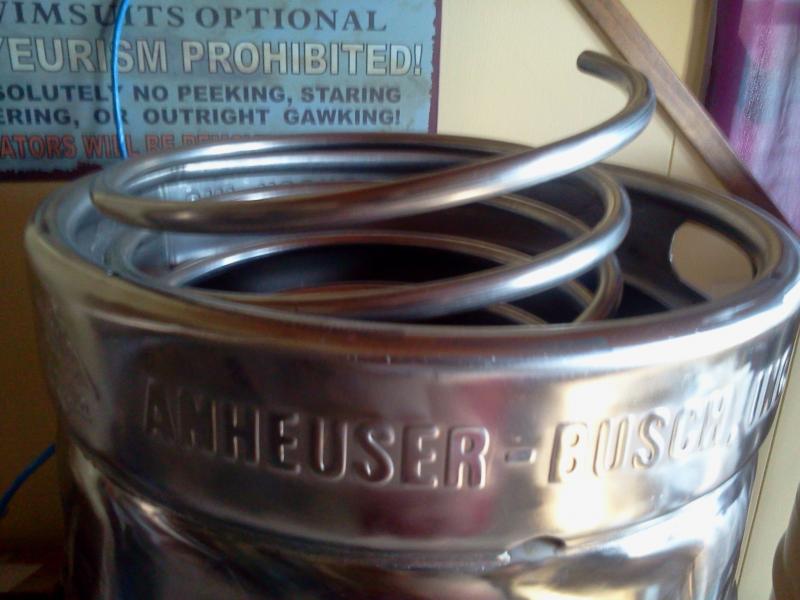

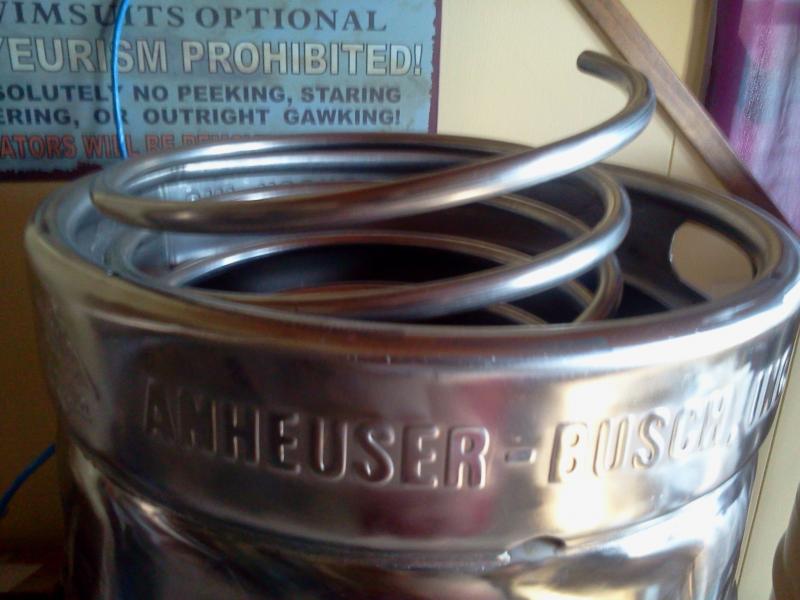

Well I hope to be installing my 50' 1/2" HERMS coil into my HLT (keggle this weekend. In looking at it it appears it is going to be a royal PITA especially the bottom fitting getting this thing in there. Especially when you have big ham hands and sausage fingers.

Any tips, tricks or ideas on how to go about this? You can see by the pics I don't have a lot of room to maneuver.

Any tips, tricks or ideas on how to go about this? You can see by the pics I don't have a lot of room to maneuver.