KellyL

Active Member

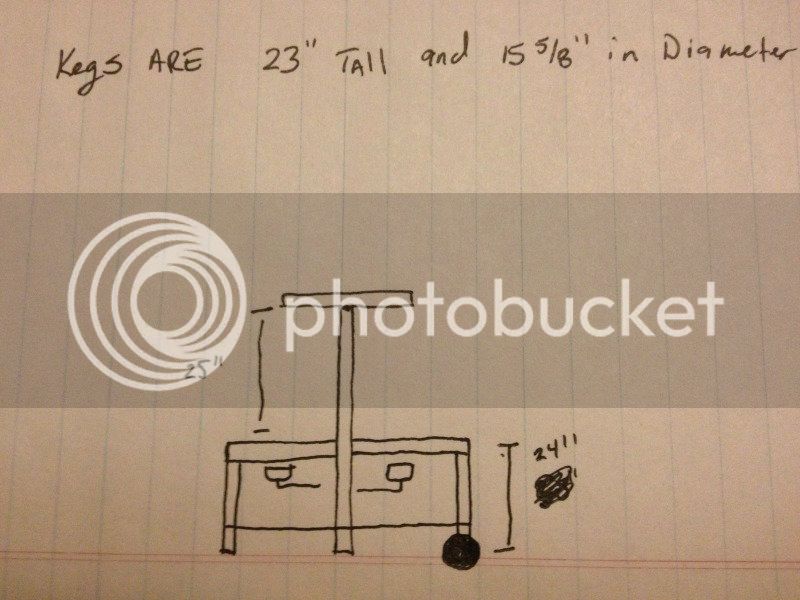

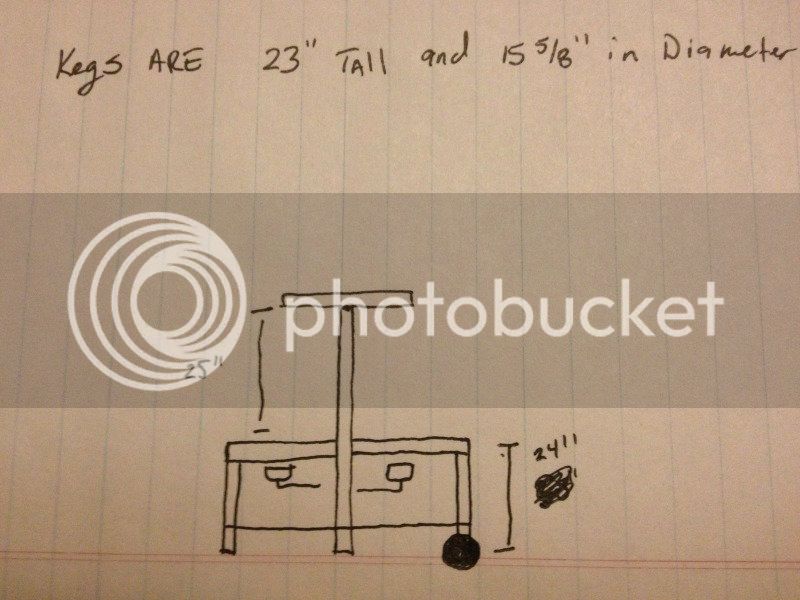

I have a friend that welds and has left over steel. I told him about my idea and he's itching to build. I'll have to buy more steel to complete it but here's my drawing. I don't have a pump but may get one soon if the expenses on this are low enough. I need something compact but cant use a 3 tier because of the height in my garage (it's the midwest and it gets COLD). I came up with this plan to keep the mash tun (cooler) away from the flame. Even without a pump I can use a pitcher for the water and gravity feed the rest. This will also help when I get a pump because I wont have to worry much about sanitation. I plan on installing a water filter as well but this should be a pretty easy, manual stand right?

Thoughts?

Thoughts?