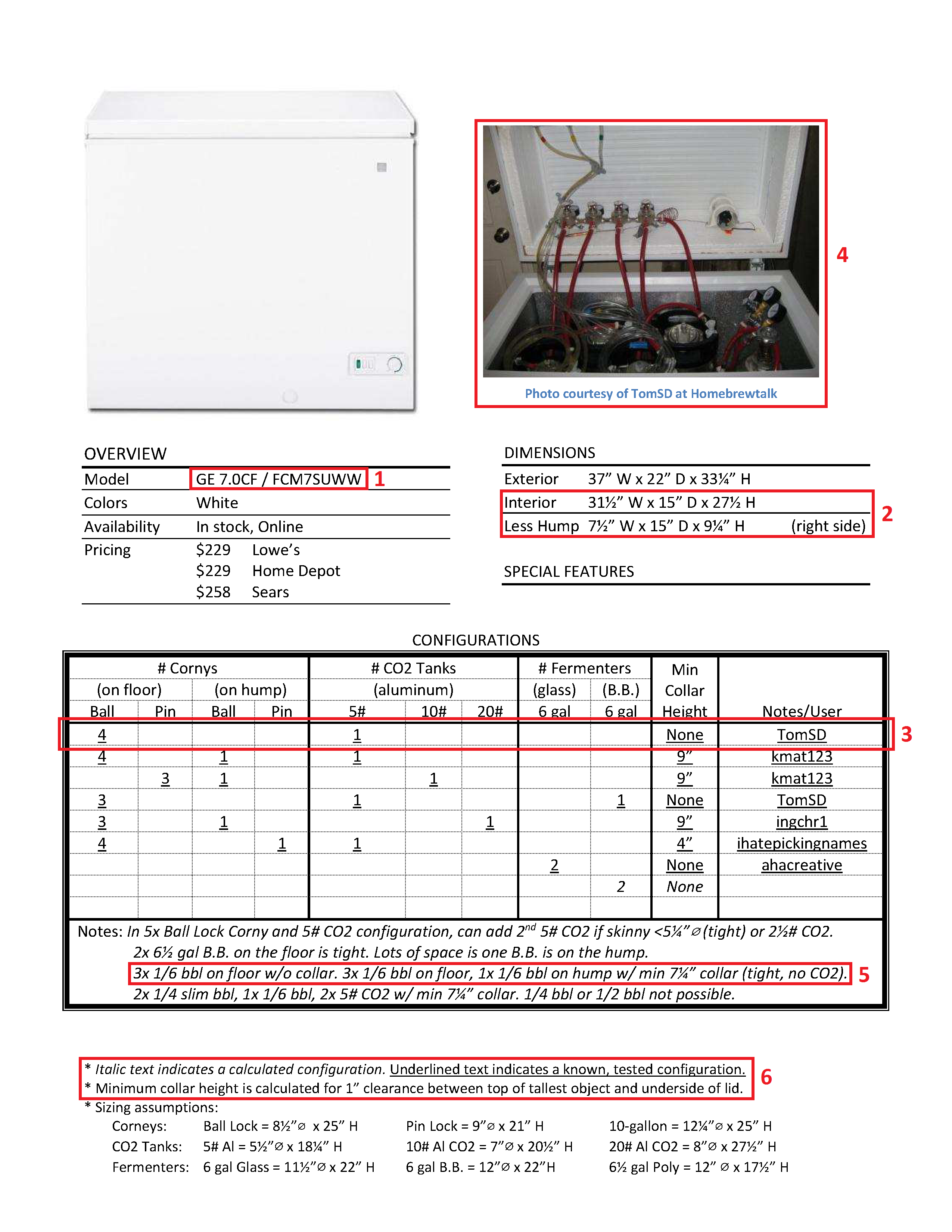

It includes 1" for disconnects and hoses.

Both of my GE 7.0's have 1x10 collars (9.25") and fit just fine with kegs on the hump.

But is it possible to go smaller?

It includes 1" for disconnects and hoses.

Both of my GE 7.0's have 1x10 collars (9.25") and fit just fine with kegs on the hump.

I'd have to imagine that lifting a full 1/2 bbl keg into a keezer, especially if there's a collar, would be highly unpleasant.

Yeah, I was looking more for a BMC beer for parties and what not.

OOOOOOHHHH well.

I'd have to imagine that lifting a full 1/2 bbl keg into a keezer, especially if there's a collar, would be highly unpleasant.

But is it possible to go smaller?

thadius856 said:Very possible to go shorter on the 7 cu ft.

But even sitting on 3" casters and doubled 2x4 frame, it's barely at the right height to be ergonomically comfortable to serve from as an almost 6'0" tall man. Without the casters or frame, I'd have to bend at the knee to hold the glass low enough.

Yeah, I gotcha. I am just concentrating on fitting the kegs in. I would rather build a taller platform than to have wasted space in the cooling compartment. So what would the minimum collar height be?

I was thinking I might be able to by-pass a temp controller by going with one of these.

I just got an Igloo 7.2 C ft chest freezer. It actually doesn't fit 4 5 gallon ball lock kegs - but I squeezed in a 2.5 gallon + 1 3 gallon with 3 5 gallon kegs + 5 lb CO2 tank. I can send pictures if you like.

I ordered a bigger Maytag CF for fermentation also ( it's my Birthday!)

Thanks for helping me decide - good thread.

Steve da sleeve

thadius856 said:Looks tight. There's a good chance that you can get 9 in there still.

I find that my cornys aren't actually round, but slightly oval. The short way across the lid seems to be smaller than the other way. That is, if you have the lid facing you with the bail at the bottom and you're above it, they're skinnier from left-to-right than top-to-bottom.

Have you checked for bulge at the foot/heel of the keg? Most kegs bulge here slightly from the rubber vulcanizing mold, and you can get a surprising amount of space back my shaving 1/16" off with a rasp.

Weird, I never saw this reply.

Anyway, I ended up building a collar our of 1x8s and am able to get 11 in. Pretty badass!

(Frigidaire 14.9)

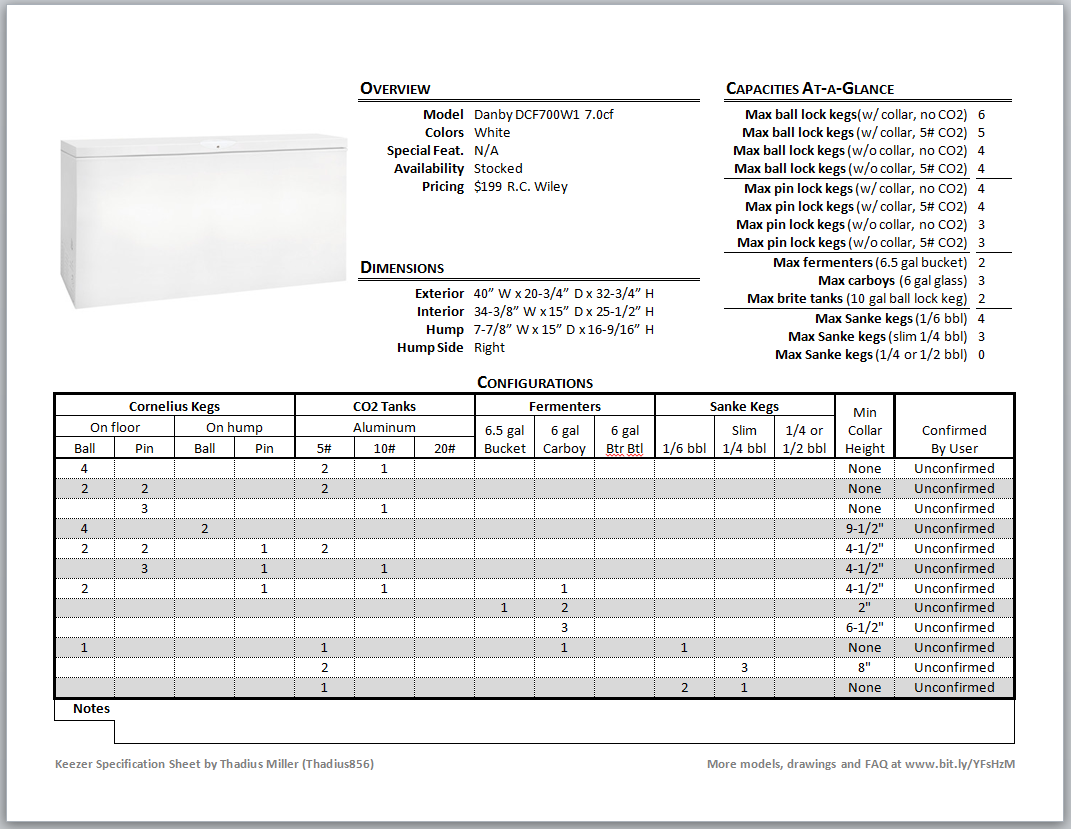

Here are the specs for the Danby 10.2 cu ft chest freezer.

[...]

- Can adjust temp without controller using the coarse set screw

ResumeMan...as to how to deal with those rounded corners...BTW Zettwoch, have you done a build thread or posted photos of your keezer anywhere? As I mentioned I'm considering that unit, and would like more info to supplement the thread I linked earlier. In particular if you built a collar I am wondering how you addressed the rounded corners.

On Thursday, I worked a full day with an obnoxious stomach ache, came home, sleep for a few hours, and woke up from pain. The dull stomach pain had migrated to a very specific location in the lower right abdomen. Yep, that's right, appendicitis. Fast forward a few hours, I was admitted to the ER, and the following morning, I was being slice n' diced on an operating room table by a laparoscopy robot. As a result, I spent my 4-day holiday weekend recovering in the hospital and at home.

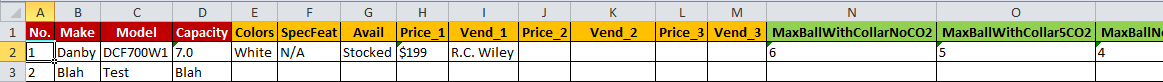

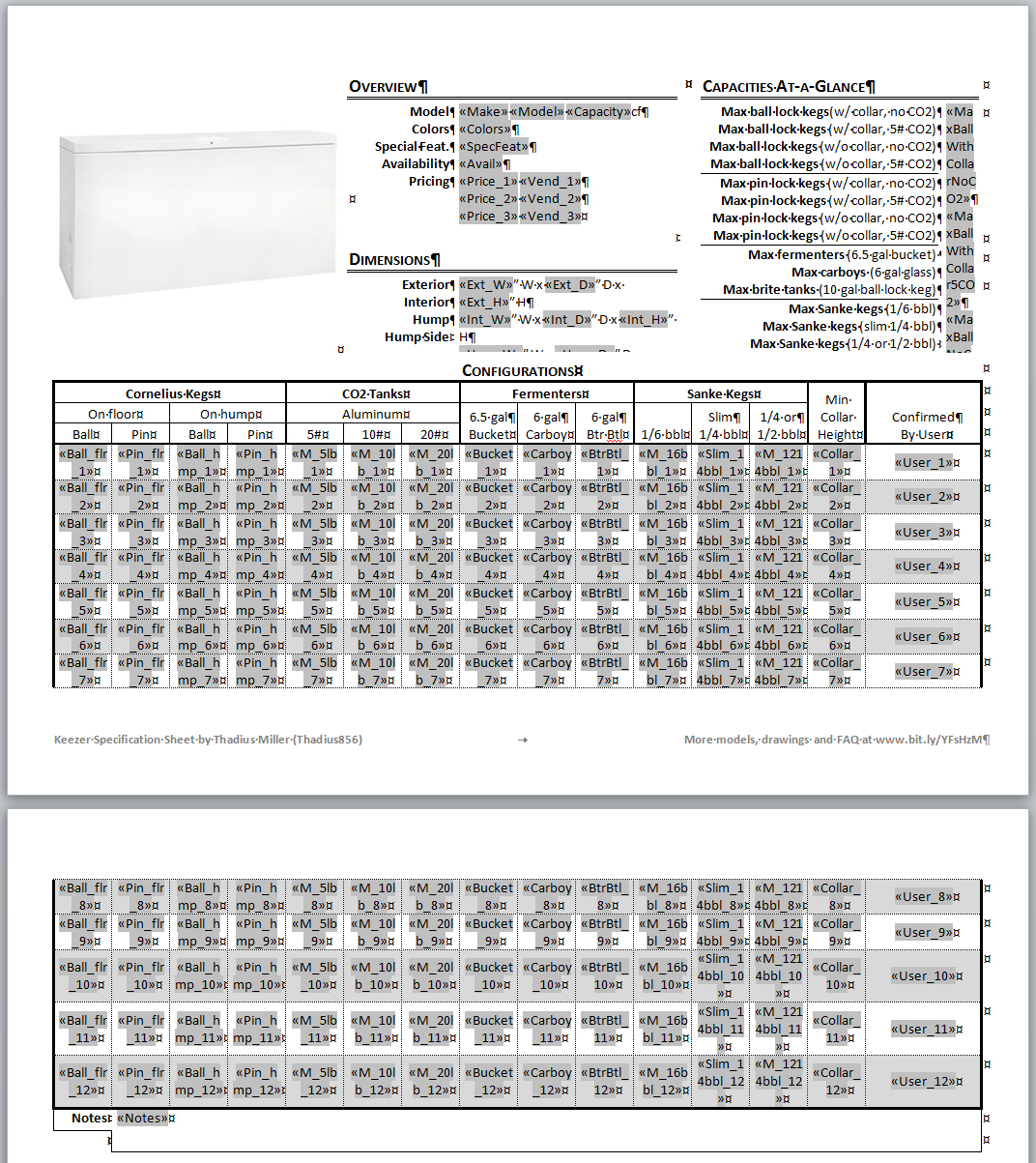

Still plugging along. Added another 3 models to my flat file, so I'm making progress. Problem is that it's super boring re-doing work that I've already done, so I only make it and hour or two before I take a "break". And that break has ended up being working on a porch screening project, prepping/weighing/organizing grains for recipes, or washing the dozen dirty kegs I had laying around.

Also spent 4-5 hours today re-arranging my AutoCAD drawing file. This should allow me to go DWG -> PDF -> PNG much more gracefully, at 2-3x the resolution from before, and with much less lossyness in the images.

I think the end result will be a much more professional end product. Bear with me a few more days.

Problem is that it's super boring re-doing work that I've already done, ...

Enter your email address to join: