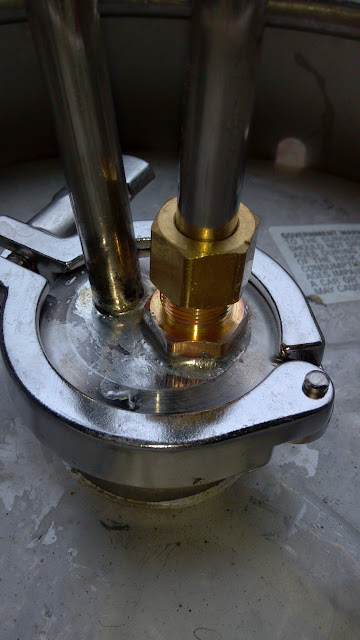

I encountered the same issue when I ordered the reducing coupling. It was slightly bigger than the OD of our 1/2" NPT couplings.

My solution was to measure my OD of the coupling with a caliper and made a mark on the reducing coupling where I wanted to stop pulling it through.

My solution was to measure my OD of the coupling with a caliper and made a mark on the reducing coupling where I wanted to stop pulling it through.