Hawgbranch

Well-Known Member

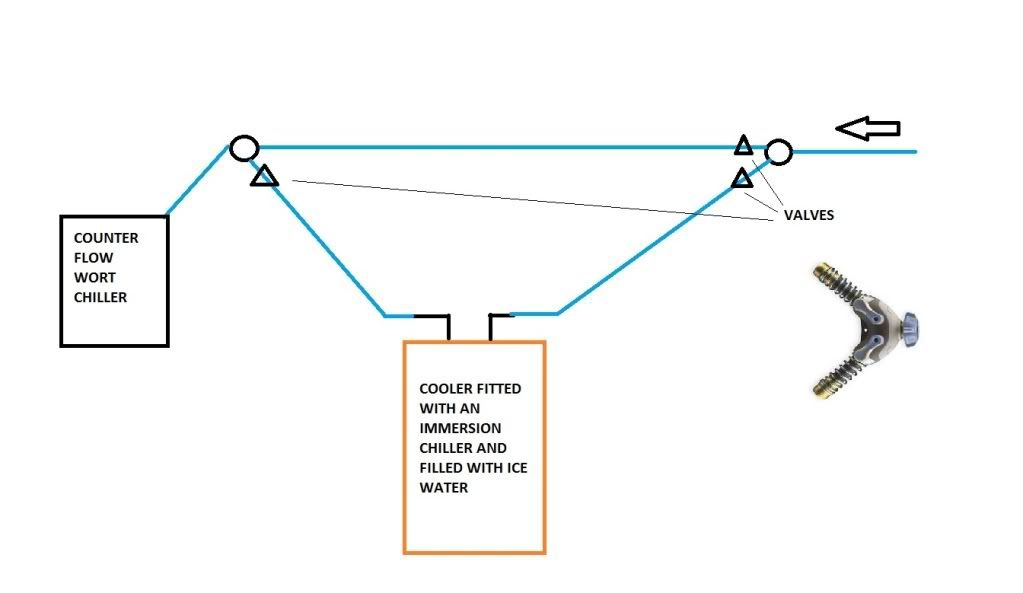

I am trying to come up with a cost effective way to help my CFC bring temps down a little lower.

Has anyone tried something like this? Will it be efficient enough to work?

I apologize for this weak rendering of my idea.

My plan is to use regular water to bring temps down as far as they will go then open the valve(s) to the cooler then mixing ice cold water in the line. I don't need that much as I can get to about 80 as is.

Thanks guys and gals!

Has anyone tried something like this? Will it be efficient enough to work?

I apologize for this weak rendering of my idea.

My plan is to use regular water to bring temps down as far as they will go then open the valve(s) to the cooler then mixing ice cold water in the line. I don't need that much as I can get to about 80 as is.

Thanks guys and gals!