You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mango Pulp Wine

- Thread starter NerdyMarie

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Shenanigan

Active Member

lpsumo said:Mine is still slowly fermenting more than 3 months later, waiting is boring...

Holy crap! Did you put the 6 cups of sugar in?

I used mango nectar with 4 cups of sugar but added yeast energizer on top of the nutrient with a half pack of red star premier cuvee. It's chugging away with a bubble every other second at 65*. Might ramp up the temp a bit over the next few days

I don't know what its deal is. I racked off the sediment, then strained the sediment and bulked it up with water to a full gallon. It sat in secondary for nearly 3 months, then I racked it to tertiary. It's been slowly bubbling in there since the end of June.

Unfortunately it's in a 1 gallon jug that I can't get a hydrometer into so I have no idea what it's SG is. It started at 1130 but I figured with all the water I used to bulk it up it'll end around 12-14%

Unfortunately it's in a 1 gallon jug that I can't get a hydrometer into so I have no idea what it's SG is. It started at 1130 but I figured with all the water I used to bulk it up it'll end around 12-14%

Hi! I've always like making "interesting" wines, so I've been following this thread with interest! When I saw the pictures I was convinced to try this recipe, so a little over a week ago I decided to take the leap and start a batch for myself. I have some observations but first, let me describe what I did...

My local grocery store had kesar mango pulp on sale for Ramadan -- $1.49 per 30oz can -- so I grabbed 12 cans so I could make a 6 gal batch with twice the fruit. Here's the recipe I used (forgive the mixed units -- I'm Canadian):

12 30 ounce cans of mango pulp (that's about 10.5 L or 2.75 Gal)

6 kg Table Sugar (that's about 13.2 lbs or 24 cups)

12.5 L water (that's about 3.25 Gal)

9 tsp white wine acid blend

3 tsp pectic enzyme

6 tsp yeast nutrient

2 tsp yeast energizer

1.5 tsp tannin

1 pkg Bentonite

1 pkg Lalvin EC-1118 yeast

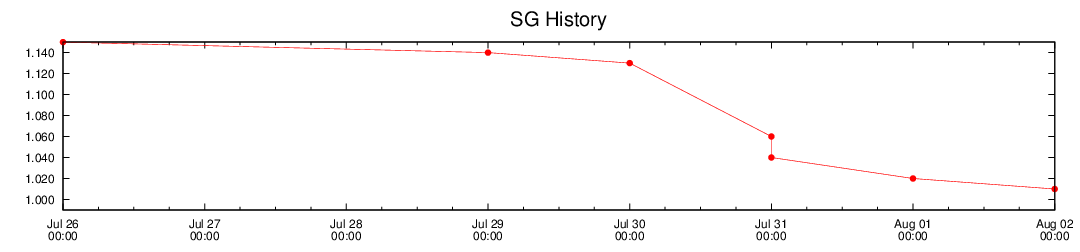

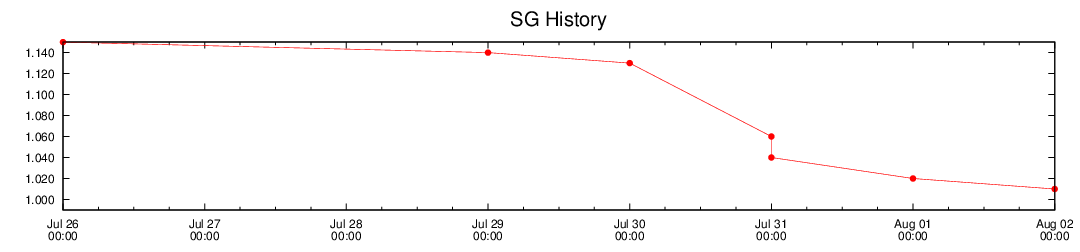

The recipe as posted above would have called for 36 cups (9 kg) of sugar, but as I was pouring in my third bag I was struck by just how much sugar I was adding. Was this going to be rocket fuel? I stopped there and completed the make and set it to ferment, then I went and did some math. I looked up the brix value for kesar mango pulp (you've got to love the internet) and found it is typically sold to consumers at 18 degrees. This means an SG of 1.075. 6 kg of sugar in 12.5 L of water has an SG of about 1.220, so blended together the mixture had an OG of 1.150. If I fermented this mixture to full dryness it would have about 20% alcohol (although Lalvin EC-1118 tops out at about 18% in perfect conditions).

I like to ferment to dry and then backsweeten if needed, so this is too high for me. What to do? Hmm...cut with water? What about the flavor I was looking for? I thought about this overnight.

It hit me the next morning: start another batch with no sugar added! This would create a batch with an OG of 1.015, which, once started I could blend with the first batch to create two batches with an average OG of 1.082 -- a nice, 10.5% ABV final result.

So, I went and got another 12 cans and started up -- it was so happy it was approaching dry a day later (!), so I grabbed a third primary pail and put half of each batch into it, then poured the remaining second batch atop the first batch. I also used my degassing wand to blend in the fruit caps thoroughly. By this time the original batch had made it down to 1.060 (wow). Blended together the two batches were each at 1.040.

Yesterday I racked both batches down to a couple of 5 gal carboys, blending the batches half and half again for good measure. I used a gallon jug for the excess -- one of my batches got a solidish fruit cap on it, the other was still in suspension, so I had only about a gallon of extra stuff. After an hour or so I noticed some airlock activity. I'll have to check the current SG when it clears a little.

Oh, and when I looked at my receipts from the grocery store I realized I'll get two batches for $36 worth of pulp and $6 worth of sugar. Not bad! Does anyone know what volume of sediment I can expect this to drop?

So -- after all this I wonder perhaps if the original recipe is a little hot? Any thoughts?

I'll throw in some images here:

SG progression

After racking yesterday (oh, and the other carboys are: 3 gal dried elderberry to the left, 6 gal dragon blood to the rear and 3 gal of strawberry to the right)

My local grocery store had kesar mango pulp on sale for Ramadan -- $1.49 per 30oz can -- so I grabbed 12 cans so I could make a 6 gal batch with twice the fruit. Here's the recipe I used (forgive the mixed units -- I'm Canadian):

12 30 ounce cans of mango pulp (that's about 10.5 L or 2.75 Gal)

6 kg Table Sugar (that's about 13.2 lbs or 24 cups)

12.5 L water (that's about 3.25 Gal)

9 tsp white wine acid blend

3 tsp pectic enzyme

6 tsp yeast nutrient

2 tsp yeast energizer

1.5 tsp tannin

1 pkg Bentonite

1 pkg Lalvin EC-1118 yeast

The recipe as posted above would have called for 36 cups (9 kg) of sugar, but as I was pouring in my third bag I was struck by just how much sugar I was adding. Was this going to be rocket fuel? I stopped there and completed the make and set it to ferment, then I went and did some math. I looked up the brix value for kesar mango pulp (you've got to love the internet) and found it is typically sold to consumers at 18 degrees. This means an SG of 1.075. 6 kg of sugar in 12.5 L of water has an SG of about 1.220, so blended together the mixture had an OG of 1.150. If I fermented this mixture to full dryness it would have about 20% alcohol (although Lalvin EC-1118 tops out at about 18% in perfect conditions).

I like to ferment to dry and then backsweeten if needed, so this is too high for me. What to do? Hmm...cut with water? What about the flavor I was looking for? I thought about this overnight.

It hit me the next morning: start another batch with no sugar added! This would create a batch with an OG of 1.015, which, once started I could blend with the first batch to create two batches with an average OG of 1.082 -- a nice, 10.5% ABV final result.

So, I went and got another 12 cans and started up -- it was so happy it was approaching dry a day later (!), so I grabbed a third primary pail and put half of each batch into it, then poured the remaining second batch atop the first batch. I also used my degassing wand to blend in the fruit caps thoroughly. By this time the original batch had made it down to 1.060 (wow). Blended together the two batches were each at 1.040.

Yesterday I racked both batches down to a couple of 5 gal carboys, blending the batches half and half again for good measure. I used a gallon jug for the excess -- one of my batches got a solidish fruit cap on it, the other was still in suspension, so I had only about a gallon of extra stuff. After an hour or so I noticed some airlock activity. I'll have to check the current SG when it clears a little.

Oh, and when I looked at my receipts from the grocery store I realized I'll get two batches for $36 worth of pulp and $6 worth of sugar. Not bad! Does anyone know what volume of sediment I can expect this to drop?

So -- after all this I wonder perhaps if the original recipe is a little hot? Any thoughts?

I'll throw in some images here:

SG progression

After racking yesterday (oh, and the other carboys are: 3 gal dried elderberry to the left, 6 gal dragon blood to the rear and 3 gal of strawberry to the right)

I'm finally fixin to have some room in my "winery closet" in the next couple weeks after I bottle up 3 bulk aging batches. So i'll finally be able to throw this mango pulp wine together. I'm contemplating starting it off in a 2 gallon plastic primary and then rack off into a gallon carboy for the secondary. Keeping the little remaining leftover in a wine bottle for topping up after another racking. Seems like there's a TON of sediment left behind after the initial racking of this wine so this may work out well.

Shenanigan

Active Member

I have a one gallon batch and the sediment takes up 1/3 of the jug. Should I expect that loss or how could I maximize the amount I get out of it?

What do you guys think about putting the mango pulp in a mesh bag inside a bucket to ferment? And then remove the bag before siphoning to a glass carboy to age. I want to minimize the amount lost to the mango pulp lees.

What do you guys think about putting the mango pulp in a mesh bag inside a bucket to ferment? And then remove the bag before siphoning to a glass carboy to age. I want to minimize the amount lost to the mango pulp lees.

I found that there was no filter, screen or other contraption which would allow me to filter the mango pulp - it would jam everything I tried!

I ended up making two batches, so when I was ready I racked them to two 5 gal carboys, the at second racking I racked the clear wine from both carboys into a third carboy, then racked the remainder of the clear to two 1 gallon jugs. As an experiment I consolidated both pulpy masses into one carboy to see if they'd separate and clarify a bit more. They did, but only slightly - there was a large settled mass taking up half the carboy, a thin layer of "clear" liquid, then a large floating mass - a cap, really.

I blended that carboy thoroughly with my degassing tools, which helped to settle the cap. I got about half a gallon of useful wine. which i combined with the two one-gallon jugs in a 3 gal carboy. I tried to filter the rest of the pulp, as I mentioned, but the long, soft fibres of the mango pulp successfully gummed up: nylon stockings, a muslin bag, a wire mesh strainer and a colander. If I had a fruit press I think I could have put it into some cheese cloth and treated it like the pressing a red wine must, but I probably would have ended up squeezing out waaaay too much starch. As it was, my manipulation created quite a starch haze in my 3 gal carboy - I needed a big hit of amylase enzyme and a bit of pectic enzyme to clear it, and as the picture may show it's not quite as clear as the first carboy...

First image: Nice, clear 5 gal carboy

Next, 3 gal carboy still with a faint haze

Then, I just checked the 3 gal again -- looks good!

I ended up making two batches, so when I was ready I racked them to two 5 gal carboys, the at second racking I racked the clear wine from both carboys into a third carboy, then racked the remainder of the clear to two 1 gallon jugs. As an experiment I consolidated both pulpy masses into one carboy to see if they'd separate and clarify a bit more. They did, but only slightly - there was a large settled mass taking up half the carboy, a thin layer of "clear" liquid, then a large floating mass - a cap, really.

I blended that carboy thoroughly with my degassing tools, which helped to settle the cap. I got about half a gallon of useful wine. which i combined with the two one-gallon jugs in a 3 gal carboy. I tried to filter the rest of the pulp, as I mentioned, but the long, soft fibres of the mango pulp successfully gummed up: nylon stockings, a muslin bag, a wire mesh strainer and a colander. If I had a fruit press I think I could have put it into some cheese cloth and treated it like the pressing a red wine must, but I probably would have ended up squeezing out waaaay too much starch. As it was, my manipulation created quite a starch haze in my 3 gal carboy - I needed a big hit of amylase enzyme and a bit of pectic enzyme to clear it, and as the picture may show it's not quite as clear as the first carboy...

First image: Nice, clear 5 gal carboy

Next, 3 gal carboy still with a faint haze

Then, I just checked the 3 gal again -- looks good!

What about filtering somehow? like siphoning through a cheese cloth or something?

I filtered mine through a grain bag, it helped.

I was really disappointed with this one. I finally stopped fermentation a few weeks ago, nearly 6 months after it started. I don't know what the issue was but it bubbled away since March 10th and went from 1.130 to 1.015. I finally used k-meta to stop the yeast, but I find it way too sweet still. It's ok mixed with club soda though, but I probably wouldn't make it again.

Bilbobaker

Member

- Joined

- Mar 6, 2011

- Messages

- 19

- Reaction score

- 0

A couple of my Cranberry wines took forever to ferment and ended a bit on the sweet side too.

thadeus_d3

Well-Known Member

I racked this yesterday and tasted a sample. This is amazing. It's only 4 months old and ready to drink. This is my favorite wine so far and so cheap to make. I'll be starting another batch soon and may even make a banana/mango wine.

buzzerj

Well-Known Member

I started this 4 days ago and fermentation has been very slow about 1 bubble every 5 seconds. Anyone have any info that could help?

Did you aerate the must to allow the yeast to respirate and increase their population for make for a good fermentation? What's your original gravity? What variety of yeast did you use? A champagne yeast such as Red Star or Lalvin EC-1118 should be a robust yeast to start a strong fermentation. One concern I have with this recipe is the addition of the acid blend at the start of fermentation. Too acidic an environment retards yeast reproduction and growth. I would add the acid blend after fermentation and before bottling. If you get desperate I'd suggest mixing up a second batch without any acid blend and then blending the batches together thereby reducing the acidity. Provide good aeration and yeast nutrient and I think you'd get a better rate of fermentation. As it is, it sounds like you are getting fermentation happening but the rate will be painfully slow. Don't worry there is usually always a fix available.

Did you aerate the must to allow the yeast to respirate and increase their population for make for a good fermentation? What's your original gravity? What variety of yeast did you use? A champagne yeast such as Red Star or Lalvin EC-1118 should be a robust yeast to start a strong fermentation. One concern I have with this recipe is the addition of the acid blend at the start of fermentation. Too acidic an environment retards yeast reproduction and growth. I would add the acid blend after fermentation and before bottling. If you get desperate I'd suggest mixing up a second batch without any acid blend and then blending the batches together thereby reducing the acidity. Provide good aeration and yeast nutrient and I think you'd get a better rate of fermentation. As it is, it sounds like you are getting fermentation happening but the rate will be painfully slow. Don't worry there is usually always a fix available.

I did aerate the must. And I used Red Star. I don't have a hydrometer so I don't know my original gravity. Is there anyway this could finish fermenting if I just leave it alone? Even if it takes forever.

TedLarsen

Well-Known Member

I just started a batch of this, with minor variations. First, in a 3 gallon batch, I used about 8 pounds of honey and 2 cups of corn sugar. Secondly, I roasted peppers -- 4 jalapenos, and 4 red chilis -- and added the roasted peppers to the must.

I suppose this will be a capsicumel, since the honey will still constitute the primary fermentable despite the corn sugar and the sugars in the mango pulp).

In any case, it's happily working away right now -- very happily! Here's how it looks so far:

I left headspace for the foaming (which it is now doing in abundance), and will top it up when racking off the primary ferment.

I suppose this will be a capsicumel, since the honey will still constitute the primary fermentable despite the corn sugar and the sugars in the mango pulp).

In any case, it's happily working away right now -- very happily! Here's how it looks so far:

I left headspace for the foaming (which it is now doing in abundance), and will top it up when racking off the primary ferment.

buzzerj

Well-Known Member

I did aerate the must. And I used Red Star. I don't have a hydrometer so I don't know my original gravity. Is there anyway this could finish fermenting if I just leave it alone? Even if it takes forever.

Yes. But it sounds like it will take a real long time. But a weak yeast could produce off flavors too. That may not be a killer for a mango wine versus one for a grape varietal but why risk it? Your yeast are the real winemakers. Why make it overly hard for them? I'd suggest looking at alternatives for measuring your pH. If it's lower than 3.0, your yeast will struggle meaning a long and weak fermentation period. If it's much lower like 2.5, it would be a wonder that the yeast would be working much at all. I suggest an optimal yeast performance pH of 3.7 - 4.6 though some say 3.4 or 3.5 would be an ok minimum pH. A pH meter might be a good tool for you to investigate this further. If low pH is your problem, maybe add 1/3 teaspoon of calcium carbonate CaCO3, stir and check pH and repeat until your pH reads 3.8. Hope this helps your fermentation. It could really help your batch.

Yes. But it sounds like it will take a real long time. But a weak yeast could produce off flavors too. That may not be a killer for a mango wine versus one for a grape varietal but why risk it? Your yeast are the real winemakers. Why make it overly hard for them? I'd suggest looking at alternatives for measuring your pH. If it's lower than 3.0, your yeast will struggle meaning a long and weak fermentation period. If it's much lower like 2.5, it would be a wonder that the yeast would be working much at all. I suggest an optimal yeast performance pH of 3.7 - 4.6 though some say 3.4 or 3.5 would be an ok minimum pH. A pH meter might be a good tool for you to investigate this further. If low pH is your problem, maybe add 1/3 teaspoon of calcium carbonate CaCO3, stir and check pH and repeat until your pH reads 3.8. Hope this helps your fermentation. It could really help your batch.

Thank you for your help. I'll see what I can do.

Xantus954

Well-Known Member

Just ordered a sixpack of mango pulp cans. Can't wait to get this one started.

My wife and I started a 6 gallon batch of this tonight. We used...

6 - 30oz cans of Swad Kesar mango pulp

27 cups of granulated sugar

3 tsp of pectic enzyme

6 tsp of yeast nutrient

1.5 tsp of wine tannin

1 package of Lalvin K1-V1116 yeast

Followed the original recipe except for the amount of sugar and we left out the acid blend until we are ready to bottle. Seems that some are having trouble with the yeast stalling so we decreased the acid until it's done fermenting and decreased the sugar to lower the OG.

Our OG is 1.104 before the yeast is added. Will keep everyone posted on our progress.

6 - 30oz cans of Swad Kesar mango pulp

27 cups of granulated sugar

3 tsp of pectic enzyme

6 tsp of yeast nutrient

1.5 tsp of wine tannin

1 package of Lalvin K1-V1116 yeast

Followed the original recipe except for the amount of sugar and we left out the acid blend until we are ready to bottle. Seems that some are having trouble with the yeast stalling so we decreased the acid until it's done fermenting and decreased the sugar to lower the OG.

Our OG is 1.104 before the yeast is added. Will keep everyone posted on our progress.

PasbitinusBluinusRibbinus

Well-Known Member

- Joined

- Mar 14, 2012

- Messages

- 284

- Reaction score

- 37

I'm running out to buy the ingredients to this, but is there really as much sugar in this as I'm thinking? About 3lbs/gallon?

buzzerj

Well-Known Member

After 7 days of fermenting in the bucket we checked the SG and it was 1.018. Went ahead and racked into a 6gallon carboy. Still chug chugging away. We used 4.5 cups per gallon instead of 6 cups and left the acid blend out to keep the ph from getting too low in order to make it easier on the yeast.

Glad to see you had a speedy and effortless primary fermentation. It appears that you avoided the slow to start fermenting or the ferments that stopped at 1.030-1.050 that others in this thread have experienced. Your result thus far should clearly demonstrate that adding the recommended quantity of acid blend prior to pitching the yeast can affect the yeast and slow or stop the fermentation. The various brands of kesar mango pulp could also vary in the citric acid content they possess. Or using too many cans of kesar mango pulp will add a greater net quantity of citric acid to the must. The net result could very well result in a too acidic environment to stress the yeast who make the wine. Your less stressed yeast are rewarding you with a fast and strong ferment. Your wine will probably fully mature much earlier too than some of ours have done. I daresay you might have a very tasty result in 4 months or less with it only getting better through 6 months or a year. Please keep us posted at your tastings through the months to come. Before bottling, then you can add your acid blend in increments to suit your taste. If the wine is too cloying (too much sweetness without any acid bite), add maybe a 1/2 teaspoon acid blend in a 1/4 cup water and stir it into the wine. Taste and repeat until the tartness and sweetness comes into a better balance for your palate. Considering the original recipe called for 1.5 teaspoons acid blend per gallon of wine you may have to repeat additions of acid blend in solution twice more for each gallon wine you've made. Alternatively, you may need little or no added acid blend at all if your wine is dry. Taste some of the wine and find out. If needed, after adding acid blend, I'd let it age for a few more weeks before bottling just to give the adjusted wine time to mature and equilibrate in bulk.

One other tip for your next batch. Some have been asking if the mango pulp, water and sugar needs to be heated at all at the start of the process. Well for the water and sugar mixture I'd say yes. You want to be sure to get all the granulated sugar into solution and the heating greatly facilitates that process but it does something else too. Sucrose (table sugar) solubility in water approximately triples as the temperature is increased to just under the boiling point and since sucrose is a disaccharide composed of glucose and fructose, the temperature of water greatly enhances hydrolysis of the glycosidic bond breaking the glucose and fructose molecules apart. This is something you really want to promote since yeast readily metabolizes glucose and fructose to make your wine. But what really promotes the hydrolysis of the glycosidic bonds is presence of, you guessed it, citric acid, which is found in the kesar mango pulp itself. You can also help this process along when you're heating up and solubilizing your granulated sugar by adding up to 6 teaspoons of lemon juice per gallon of your batch. I'd actually suggest adding just 3 teaspoons per gallon to not overdo the acid again. But this is where acid is the winemaker's friend in breaking down the sucrose into the monosaccharides that the yeast easily devour to make alcohol. This step will greatly improve the fermentation and you as the winemaker will have done everything you can to speed the process to have a fully mature wine months earlier. That is why the initial recipe added acid blend at the start but I think the quantity called for plus the citric acid already in the mango pulp was just too much for the yeast to handle as evidenced by some of our winemakers in this thread. Yes, the right amount of acid at the start of the process is useful and the citric acid already in the kesar mango pulp may actually be adequate for that purpose as your fermentation result suggests to all of us. But definitely heating the initial water/sucrose mixture in the presence of the kesar mango pulp is a very beneficial part of the process as is providing the recommended yeast nutrient as the solution has cooled to help the yeast reproduce and get their population increased rapidly to begin a strong fermentation. Your yeast will thank you with a strong quick ferment and a mature, good tasting wine much earlier than some here are experiencing.

One additional point to mention. I see you specifically reduced the amount of mango pulp/sugar to give you a lower O.G. at the start. Nerdymarie used a strong champagne yeast precisely since she had a high O.G. and was expecting a 15-16% ABV with her wine. Some here may be using a yeast variety that might finish fermentation when the wine has say a 14% ABV but with excess, more complex sugars remaining in solution, the resulting F.G. reading will remain elevated because the wine itself is sweet. So for those who are attempting this wine and who want a dry result, remember that the mango pulp can physically affect your initial O.G. reading by helping to suspend your hydrometer in solution giving you an otherwise lower than actual O.G. reading and your yeast variety does matter. Likely a champagne yeast will be needed to fully convert all the digestible sugars to alcohol as long as the O.G. isn't so high as to result in 18% or greater %ABV. If you want to use another non-champagne yeast for a batch, I'd suggest adjusting your sugar addition to ensure that yeast can fully convert the digestible sugars before it tops out.

We look forward FF500 to hearing how your batch is proceeding because your batch is giving us all a really good and useful example of an excellent and efficient fermentation process. Watch your fermentation temperatures closely and you should have a really exemplary and excellent mango pulp wine on your hands very soon. We are learning some valuable winemaking lessons with you. Please keep us posted on how it's coming along. Salud!

buzzerj

Well-Known Member

That's the way to do it. It's looking real good. Everyone take note. Caring for your yeast speeds your batch's fermentation and gives you a good Mango Pulp wine much sooner. Great job FF500! You're the man!

Bilbobaker

Member

- Joined

- Mar 6, 2011

- Messages

- 19

- Reaction score

- 0

But some yeast's needs are different.. a cold ferment is sometimes delicious.

Hey Guys,

Is anyone else having a problem siphoning this wine? I started a batch of this wine three weeks ago and I went to rack it today, but it refused to take vacuum and transfer (using an auto-siphon). Is there any chance that my wine is too thick to transfer? I have a good amount of experience siphoning stuff and no other batch has ever given me this much trouble. The auto-siphon functioned perfectly fine when I was sanitizing it. I also switched out the tubing and switched to a racking cane with no success. Is anyone else having this problem and does anyone know how I can solve it? For now, I am going to pour the bit I managed to transfer back into the original carboy and await any advice.

Many thanks,

M4rotku

Edit: Never mind; I found the problem. Previous batches, I had affixed a square of cheese cloth to the end of my siphon to act as a filter. This wine, however, was too thick to go through the cheese cloth fast enough to create a vacuum. Unfortunately, without my cheese cloth, I lost a little over 1/4 of the wine to the thick lees. On a more positive note, the wine smelled delicious and I am very much looking forward to drinking it.

Is anyone else having a problem siphoning this wine? I started a batch of this wine three weeks ago and I went to rack it today, but it refused to take vacuum and transfer (using an auto-siphon). Is there any chance that my wine is too thick to transfer? I have a good amount of experience siphoning stuff and no other batch has ever given me this much trouble. The auto-siphon functioned perfectly fine when I was sanitizing it. I also switched out the tubing and switched to a racking cane with no success. Is anyone else having this problem and does anyone know how I can solve it? For now, I am going to pour the bit I managed to transfer back into the original carboy and await any advice.

Many thanks,

M4rotku

Edit: Never mind; I found the problem. Previous batches, I had affixed a square of cheese cloth to the end of my siphon to act as a filter. This wine, however, was too thick to go through the cheese cloth fast enough to create a vacuum. Unfortunately, without my cheese cloth, I lost a little over 1/4 of the wine to the thick lees. On a more positive note, the wine smelled delicious and I am very much looking forward to drinking it.

Damn I'm in California not sure where to go to get this mango pulp suppose I should order it on line I'm making this for summer if I start now it will be ready to drink june july I think I'm going to reduce the sugar and use corn sugar not table sugar anyone have any thoughts ?

Sent from my SAMSUNG-SGH-I747 using Home Brew mobile app

Sent from my SAMSUNG-SGH-I747 using Home Brew mobile app

RegarRenill

Well-Known Member

- Joined

- Nov 13, 2013

- Messages

- 286

- Reaction score

- 52

Try going to a Latino ethnic store or market, they should probably have them there. It's in the "ethnic" aisle at my supermarket and its a South American fruit, afaik...

buzzerj

Well-Known Member

My local supermarket in West Milwaukee has a number of good ethnic aisles and the Swad Kesar Mango Pulp is regularly priced at $2.39 for a 30 oz. can. They had another brand (Peep) for $1.50 a can on sale except the cans were all dented. I got the Swad Kesar Mango Pulp. Still really reasonable.

It does come around fairly quickly, but be prepared to wait out its separation (some of the pulp will float, some will sink, LOL).

Canned mango pulp is often in the section of the grocery store where you find things for Ramadan or Eid.

Canned mango pulp is often in the section of the grocery store where you find things for Ramadan or Eid.

...I was just wondering the differences between corn and cane sugar when brewing...

Corn sugar is Dextrose, a pretty simple sugar. It ferments fast and clean -- I suppose this is why it's favoured for priming carbonation in beer bottles.

Cane sugar is Sucrose, which is a little more complex and the yeast has to work a bit harder to process it -- it's cheaper, though...

Thanks sgx2 for me out here cornsugar is cheaper then cane or maybe my brewstore is just reasonable now is cane sugar sweeter or is corn that's probably what I should have asked

Sent from my SAMSUNG-SGH-I747 using Home Brew mobile app

Sent from my SAMSUNG-SGH-I747 using Home Brew mobile app

... is cane sugar sweeter or is corn t...

My understanding is that cane sugar (sucrose) is somewhat sweeter, you'll have to look at the recipe and scale accordingly.

I think that corn sugar is 3/4 the sweetness vs. sucrose.

thadeus_d3

Well-Known Member

I made this wine and it was incredibly sweet. I'm a huge fan of dessert wine, but I could not drink more than a glass. I decided to cut my batch of mango wine in half and start 2 batches of Niagara Mango wine using 8 cans of Welches Niagara concentrate in each. Hopefully it turns out well.

Similar threads

- Replies

- 0

- Views

- 214