WalterAtMarchPump

Well-Known Member

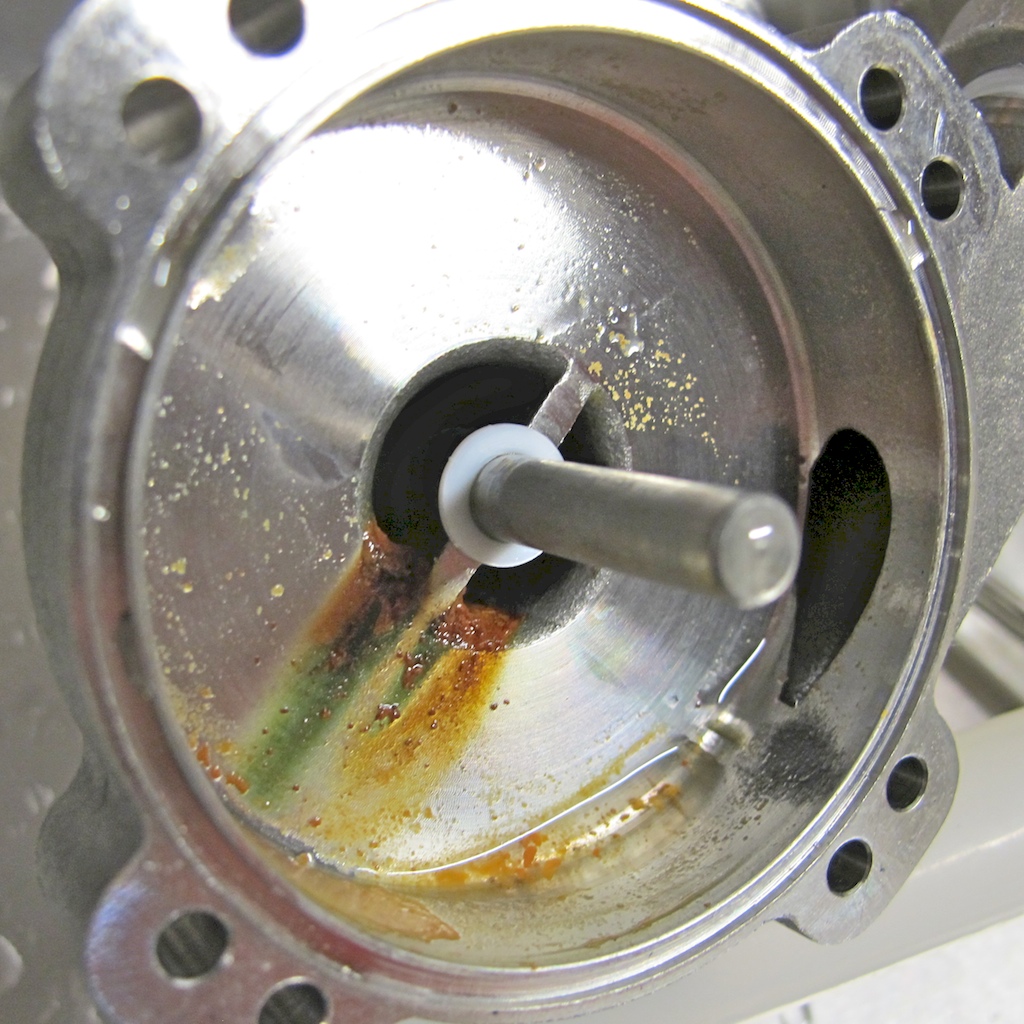

Is the shaft tight in the pump head when you took it apart? And does the impeller spin freely on the shaft? How's the teflon thrust washer looking? Should be either black or white and sit on the shaft between the impeller and the front housing.

From the vid it sounds like the impeller is too loose inside the pump head for some reason. but hard to say without having it in front of me to see first hand.

From the vid it sounds like the impeller is too loose inside the pump head for some reason. but hard to say without having it in front of me to see first hand.