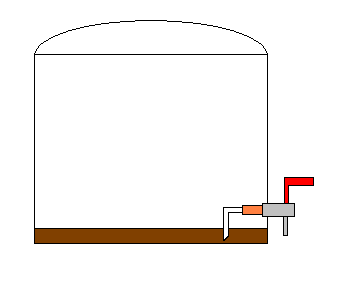

I'm not clear on the proper elbow. Shouldn't we be using CPVC? I use my bottle bucket for my mash tun running, so could have temps above 140. Stopped by an Ace store yesterday and they didn't have it in CPVC, only PVC. Clerk said they don't even carry a CPVC elbow with one end threaded, only ones that would require gluing.

Thanks for any help,

Robert

Thanks for any help,

Robert

Just bought the elbow; I'll try it tonight! Thanks again!