wilfonzo

Well-Known Member

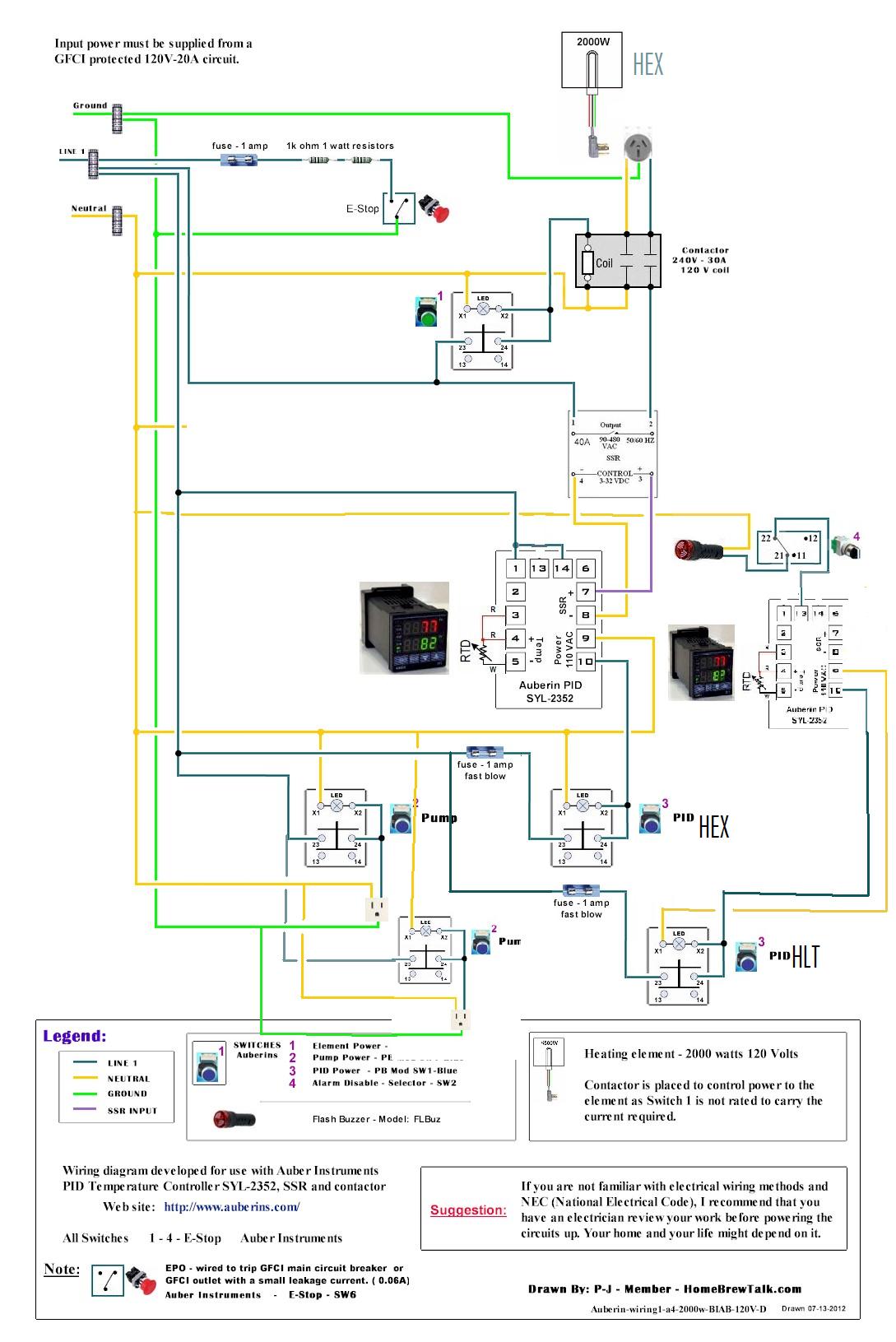

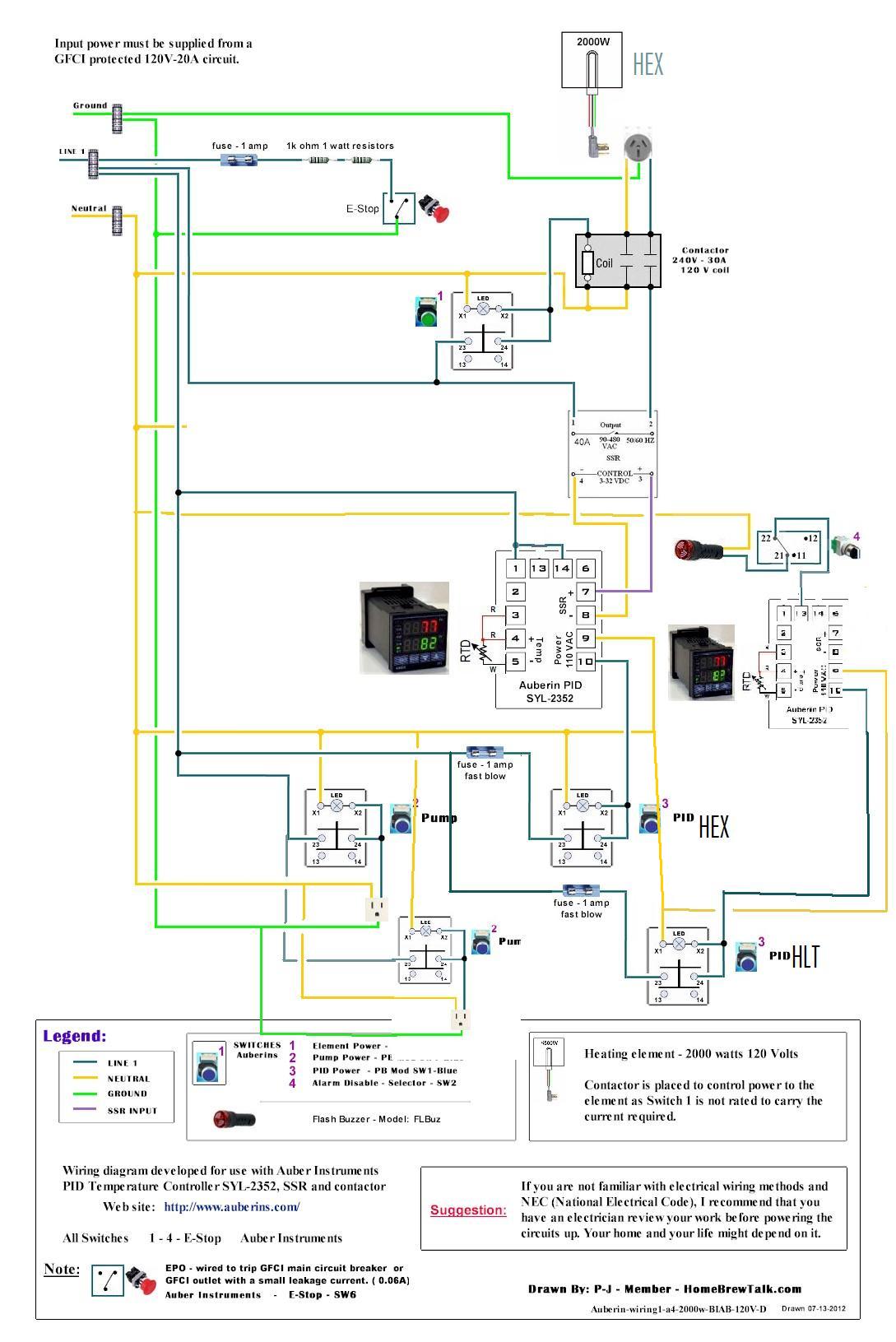

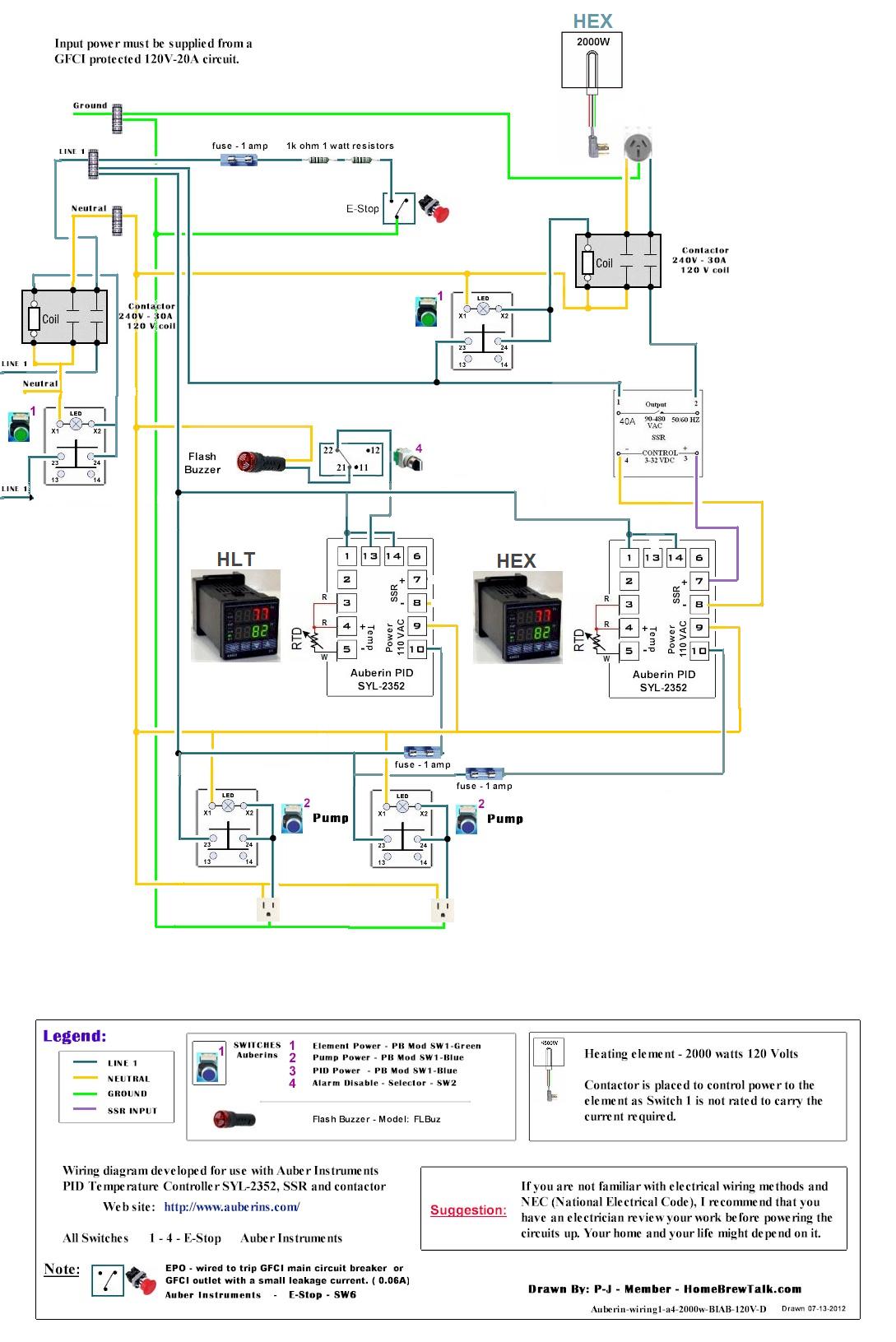

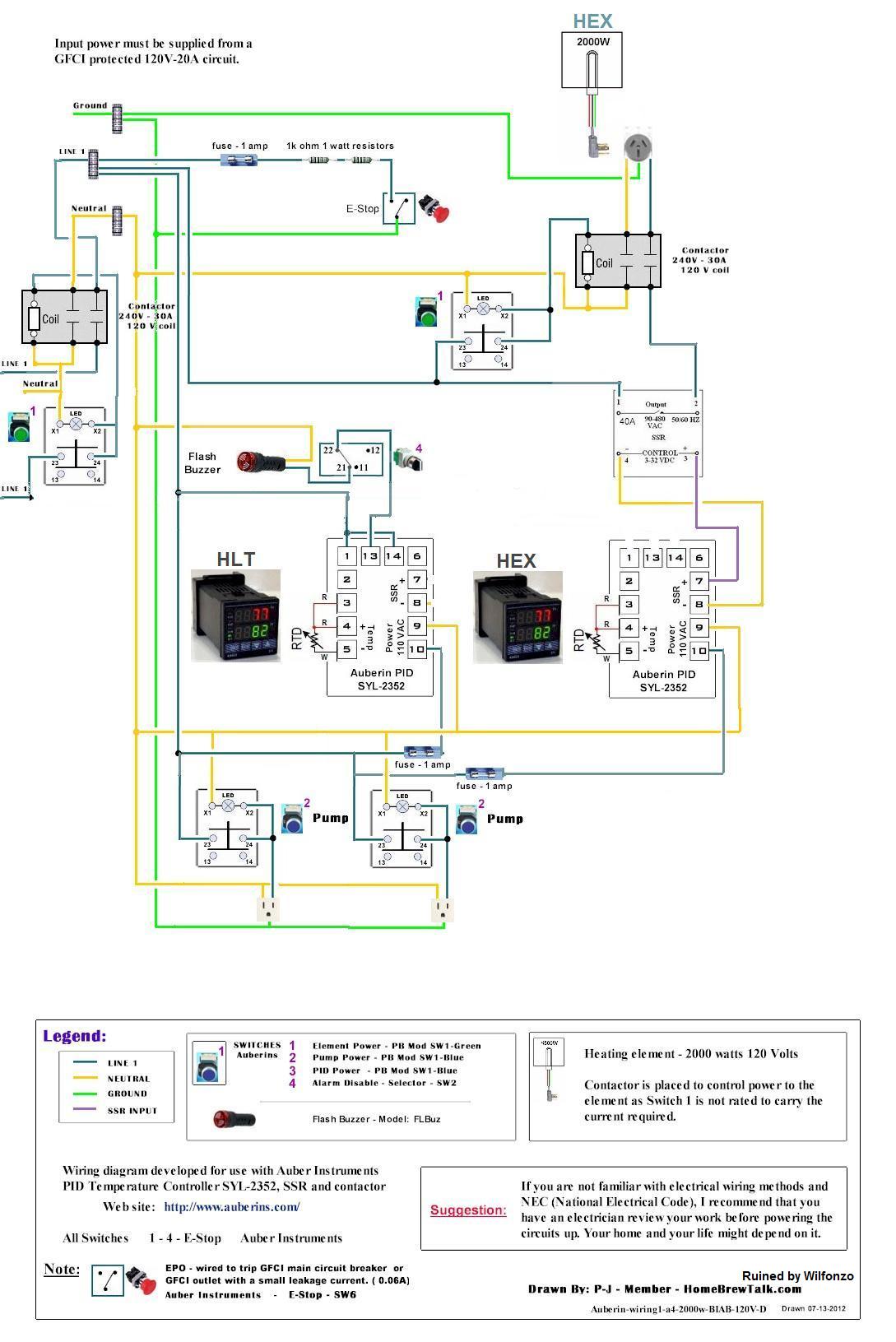

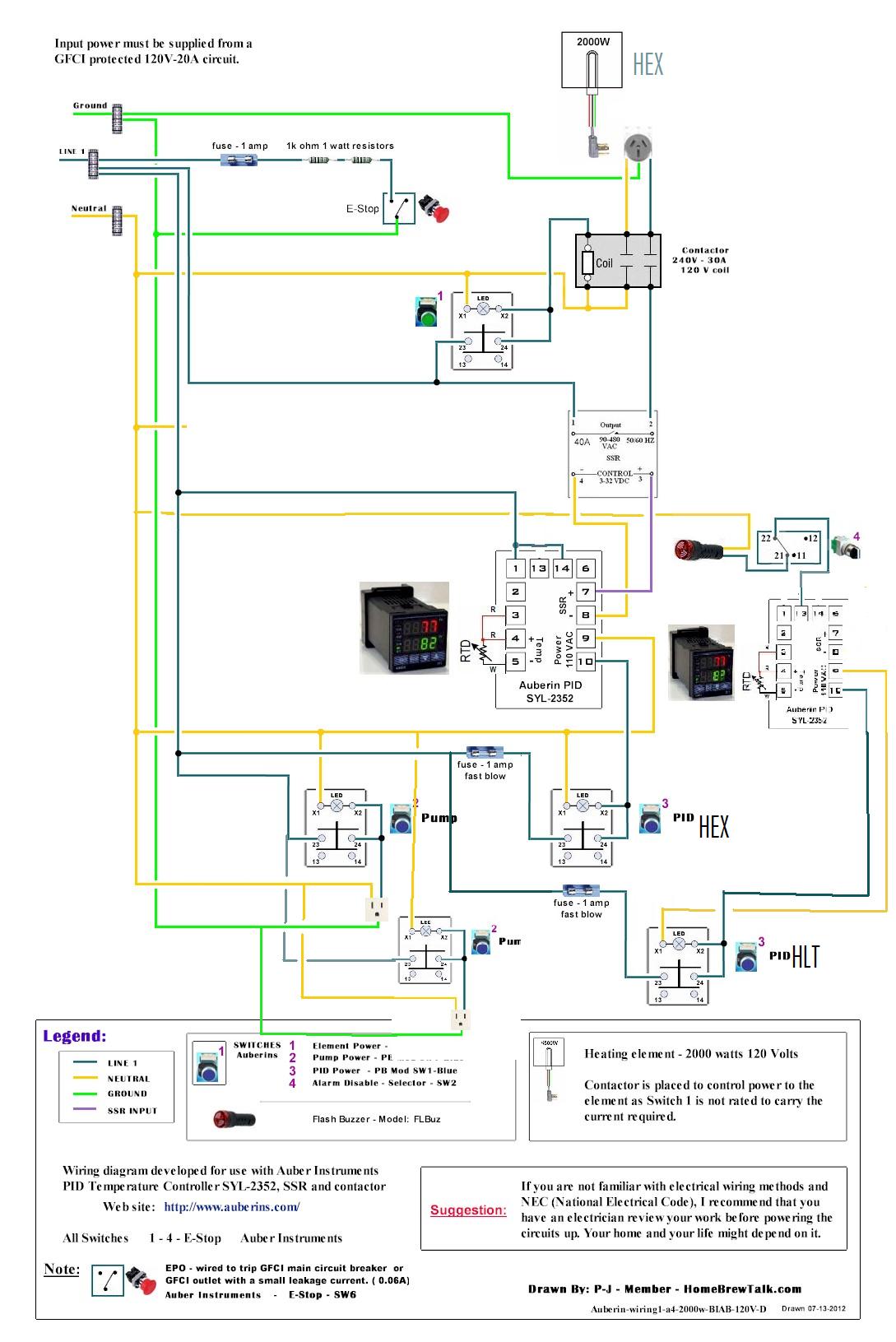

Here is what I am trying to accomplish.

-110v 2000w

-(2) 12v pumps (2amp?)

-PID with alarm for the HLT (only used as thermometer for the time being)

-PID controlled eHERMS (2000w in a 3 gallon keg with 20' 1/2" coil)

I hacked up the 110v BIAB diagram that P-J made to fit what I (think) need. Just want to run it by everyone to make sure it looks safe and functional.

-110v 2000w

-(2) 12v pumps (2amp?)

-PID with alarm for the HLT (only used as thermometer for the time being)

-PID controlled eHERMS (2000w in a 3 gallon keg with 20' 1/2" coil)

I hacked up the 110v BIAB diagram that P-J made to fit what I (think) need. Just want to run it by everyone to make sure it looks safe and functional.