In my stimulus-overload of a search across these forms, I have yet to find a simple jig for cutting the bottom off a keg.

I had a few simple criteria to accommodate when I was trying to tackle this problem.

I really wanted as close to a perfect circle as I could get. I didn't want to have to try and drill a hole in the center of the bottom of the keg. And I didn't want the grinder to be able to get away from me no matter what.

Although my amazing girlfriend had scored me some kegs; I pondered the issue of cutting off the bottoms for a few months (knowing that I wont get everything together for my full rig until the end of the year). It was not until I was cleaning the garage that I noticed these triangular pieces in my cut-off bin (if you dont have one, start one). 4 of these should be able to trace the outer circle of the keg easily.

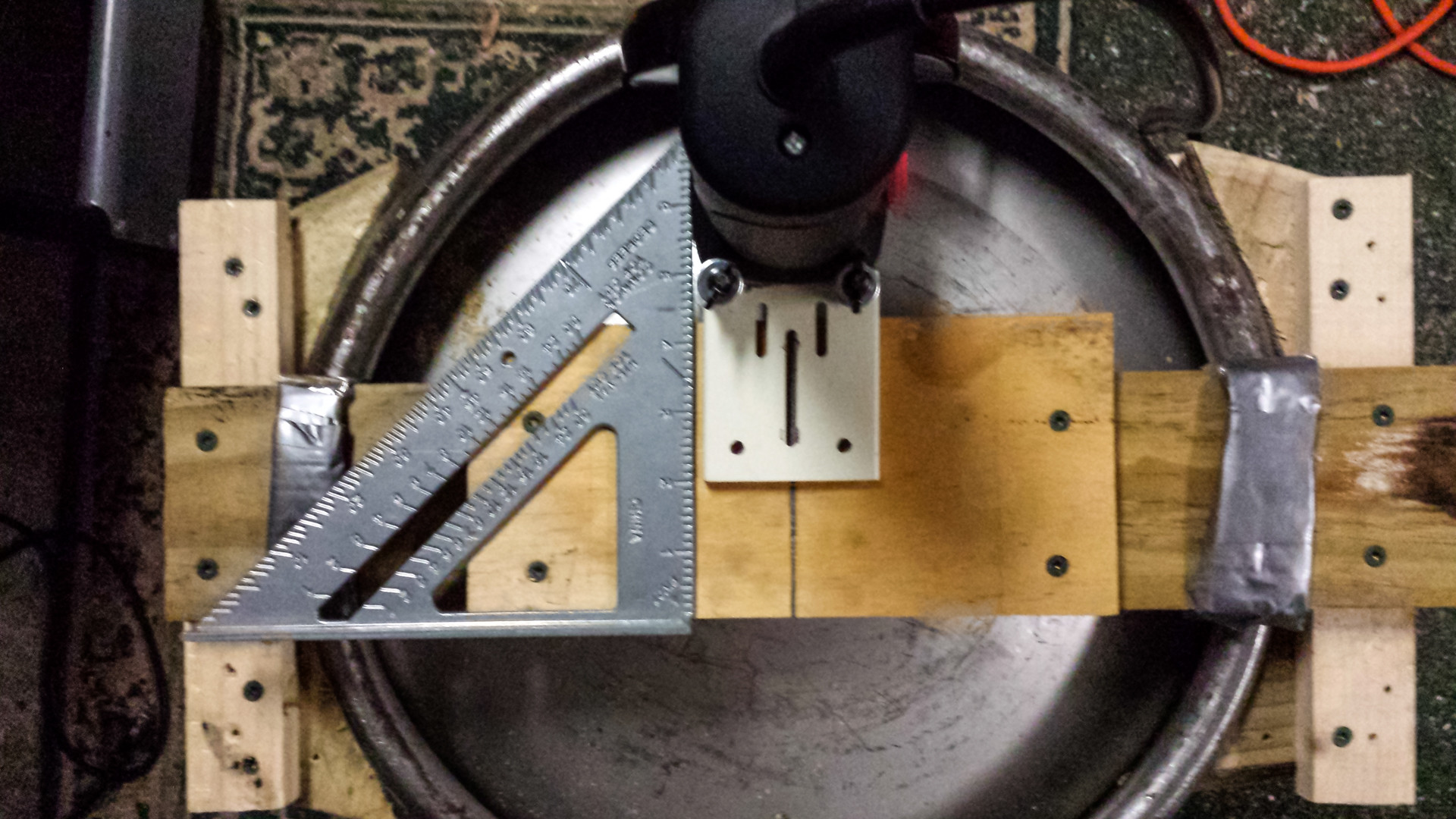

With that I built a capital I shape out of more scrap wood, on to which I mounted the triangles. I used a thin strip on the bottom of the triangles to make them more ridged

When I mounted the triangles I left one of the four with only one screw in it.

This was so that I could make a slight adjustment on how the jig fit the keg since both my kegs were dented and not perfectly round.

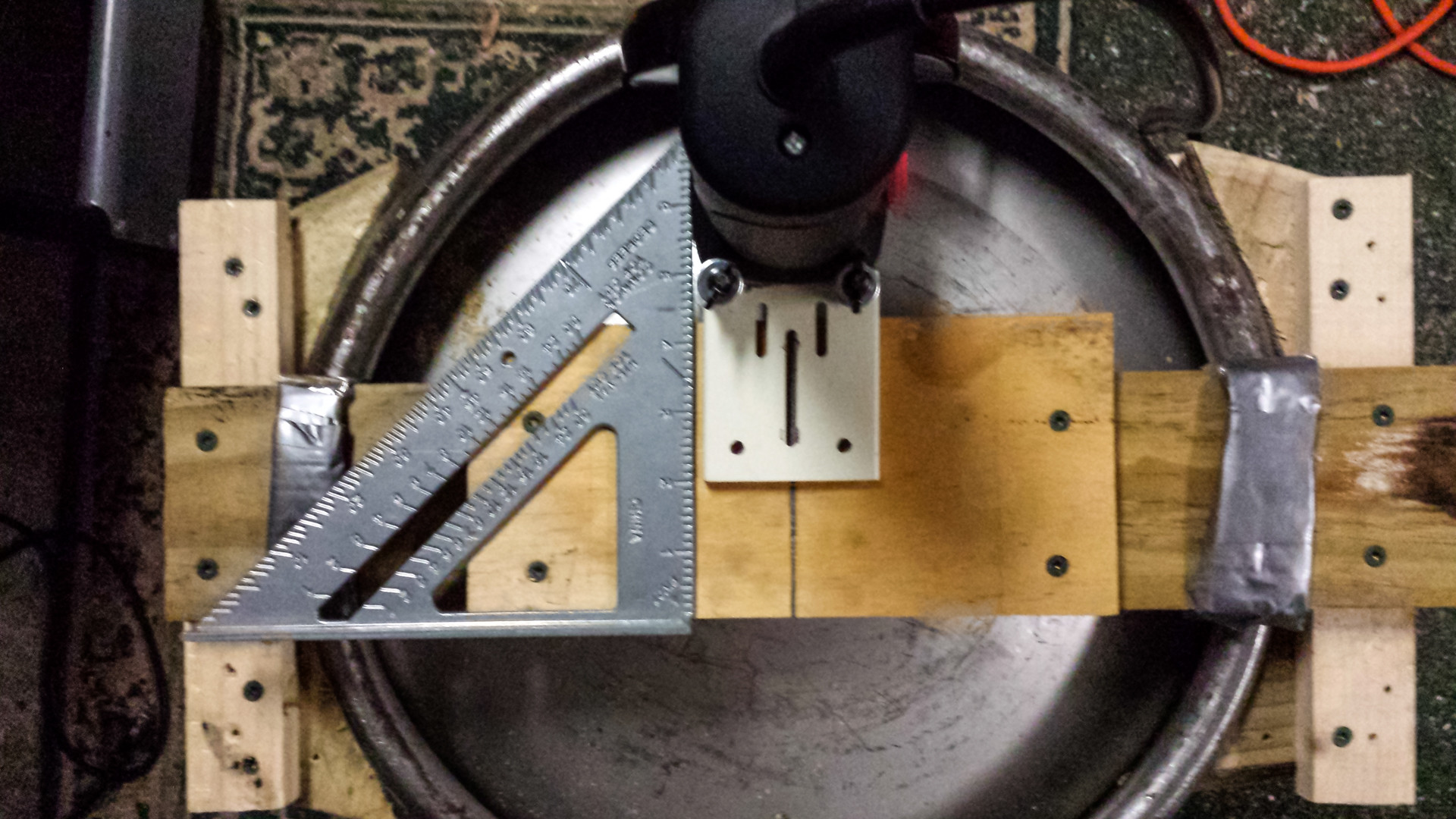

The other thing that played in to my favor was the harbor freight cheap-o angle grinder. There are two loops/triangles in the cast housing of the tool that are perfect for mounting to.

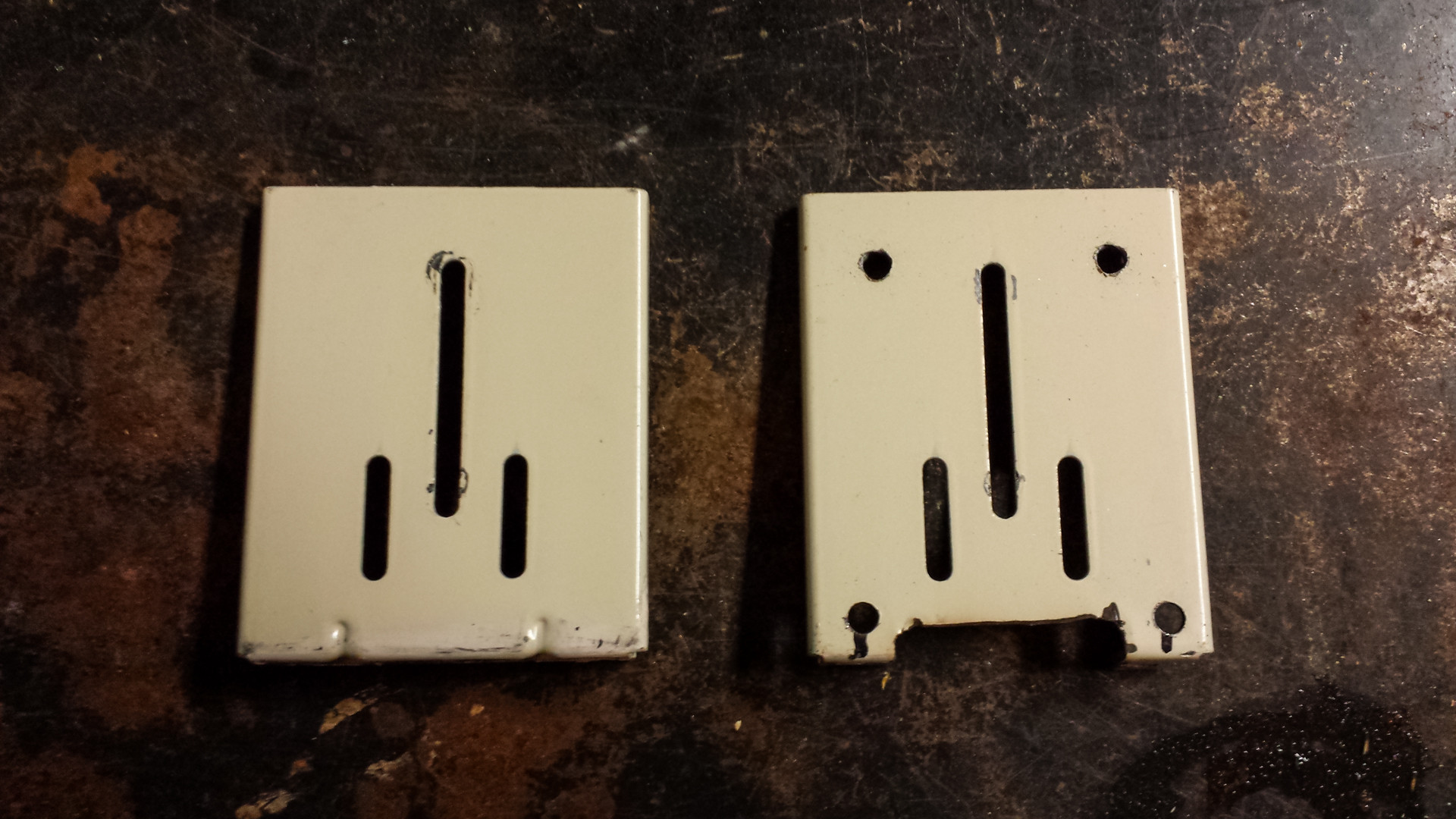

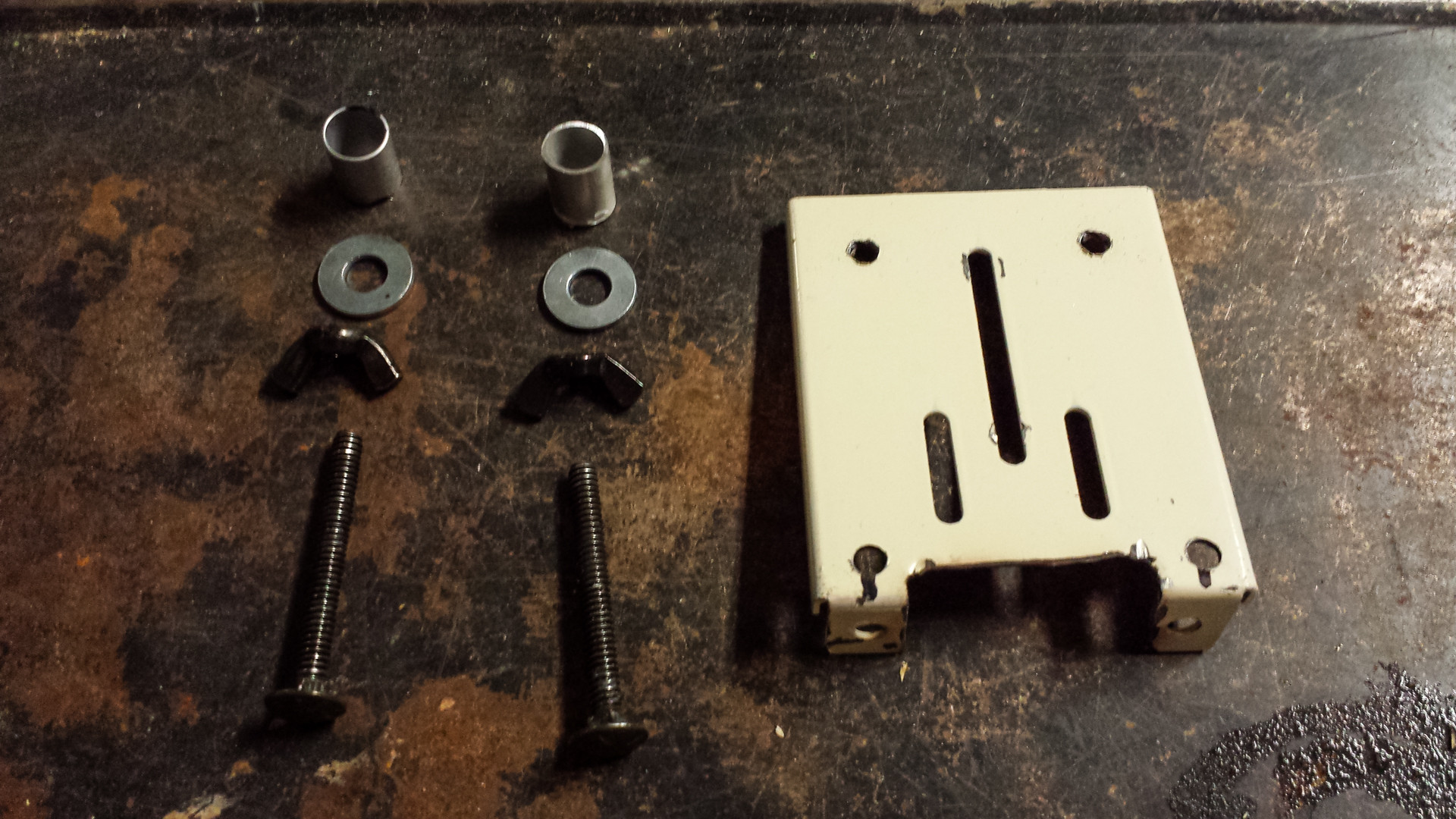

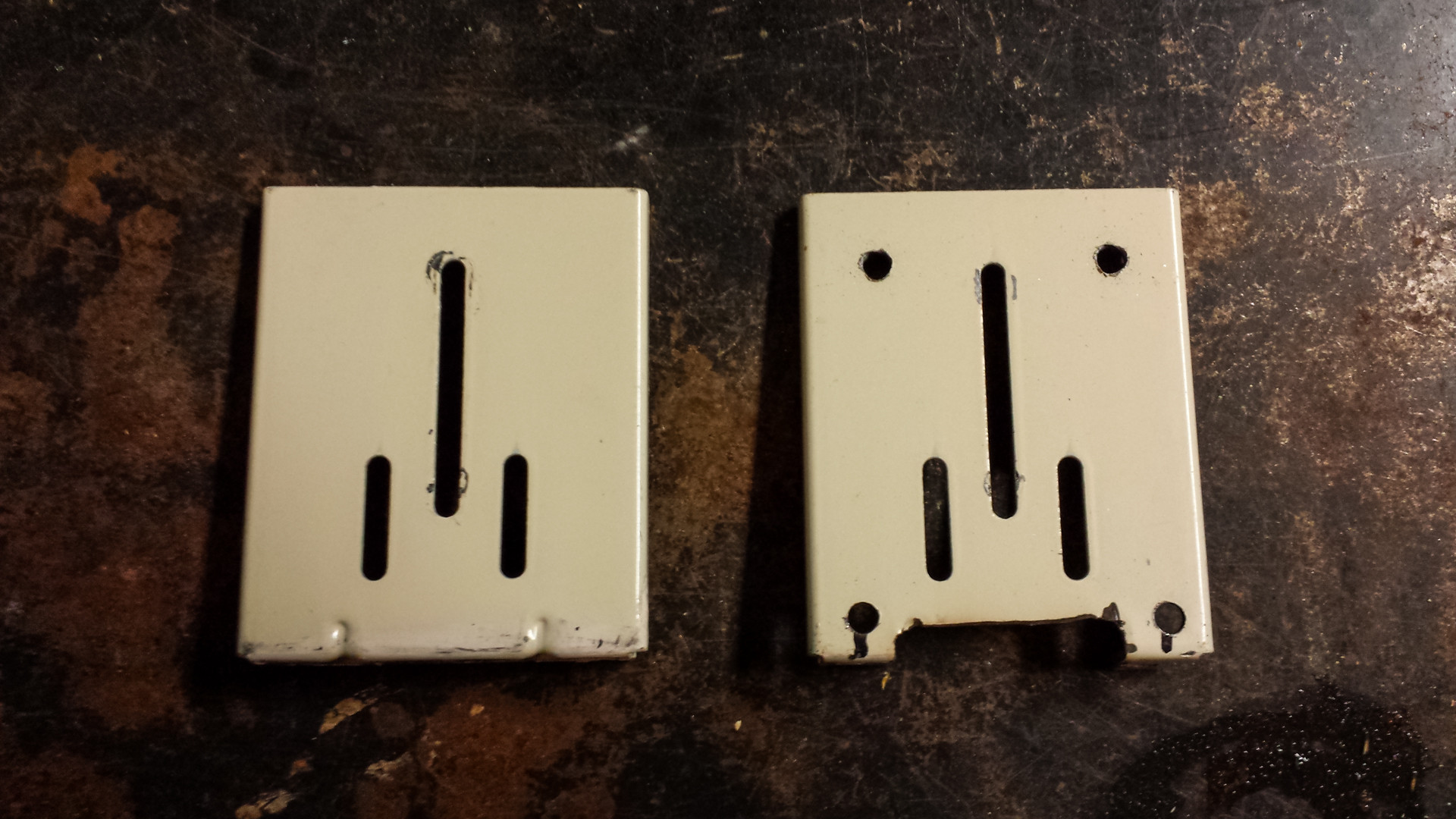

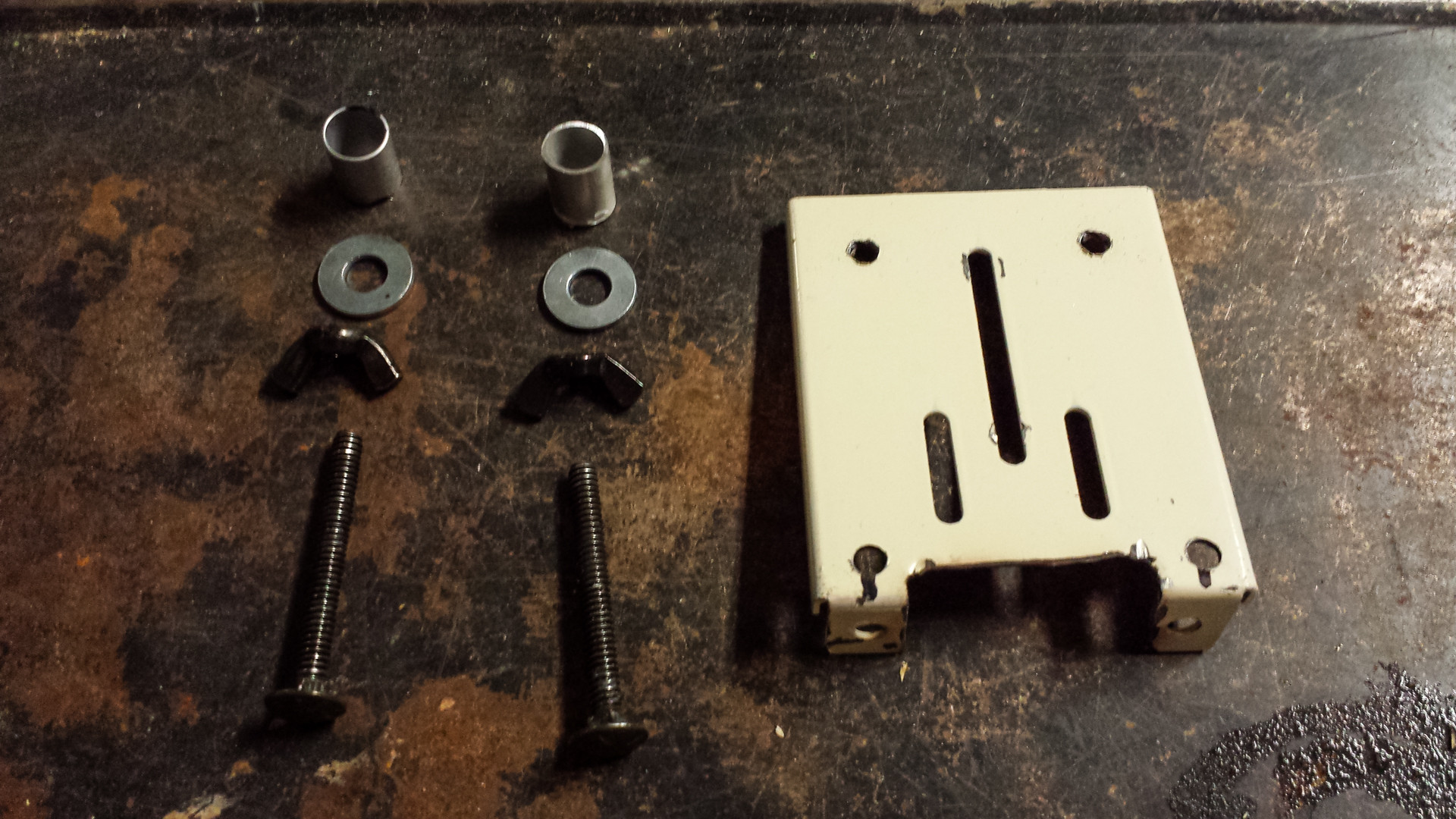

A steel mounting bracket from an old curtain rod, after some slight modification, became the mounting point for the angle grinder.

The bolts and wing-nuts were found in a jar somewhere.

I had to create a spacer for the wing-nuts since they could not screw down all the way. I used an aluminum tube that I believe came from a tent.

here is the whole mounting bracket disassembled and assembled.

I had to add a piece of scrap to the jig to get the grinder to the correct height off the keg. You want about 1.5inches from the keg ring to the mounting plate.

I also taped some reflectex to the underside of the jig, and greased the ring of the keg where they touched; these both gave it some give and allowed it to slide.

And then I just let it rip.

while not prefect i got pretty damn close to a 13" cutout all round. After hitting the one keg with a 80grit flap disk and medium gator pads its at 13.5" diameter.

I hope this helps out some people on here and for those that are wondering what i have been doing with the cut out, here's what i've got so far, just waiting on more cutting disks.

I had a few simple criteria to accommodate when I was trying to tackle this problem.

I really wanted as close to a perfect circle as I could get. I didn't want to have to try and drill a hole in the center of the bottom of the keg. And I didn't want the grinder to be able to get away from me no matter what.

Although my amazing girlfriend had scored me some kegs; I pondered the issue of cutting off the bottoms for a few months (knowing that I wont get everything together for my full rig until the end of the year). It was not until I was cleaning the garage that I noticed these triangular pieces in my cut-off bin (if you dont have one, start one). 4 of these should be able to trace the outer circle of the keg easily.

With that I built a capital I shape out of more scrap wood, on to which I mounted the triangles. I used a thin strip on the bottom of the triangles to make them more ridged

When I mounted the triangles I left one of the four with only one screw in it.

This was so that I could make a slight adjustment on how the jig fit the keg since both my kegs were dented and not perfectly round.

The other thing that played in to my favor was the harbor freight cheap-o angle grinder. There are two loops/triangles in the cast housing of the tool that are perfect for mounting to.

A steel mounting bracket from an old curtain rod, after some slight modification, became the mounting point for the angle grinder.

The bolts and wing-nuts were found in a jar somewhere.

I had to create a spacer for the wing-nuts since they could not screw down all the way. I used an aluminum tube that I believe came from a tent.

here is the whole mounting bracket disassembled and assembled.

I had to add a piece of scrap to the jig to get the grinder to the correct height off the keg. You want about 1.5inches from the keg ring to the mounting plate.

I also taped some reflectex to the underside of the jig, and greased the ring of the keg where they touched; these both gave it some give and allowed it to slide.

And then I just let it rip.

while not prefect i got pretty damn close to a 13" cutout all round. After hitting the one keg with a 80grit flap disk and medium gator pads its at 13.5" diameter.

I hope this helps out some people on here and for those that are wondering what i have been doing with the cut out, here's what i've got so far, just waiting on more cutting disks.