Golddiggie

Well-Known Member

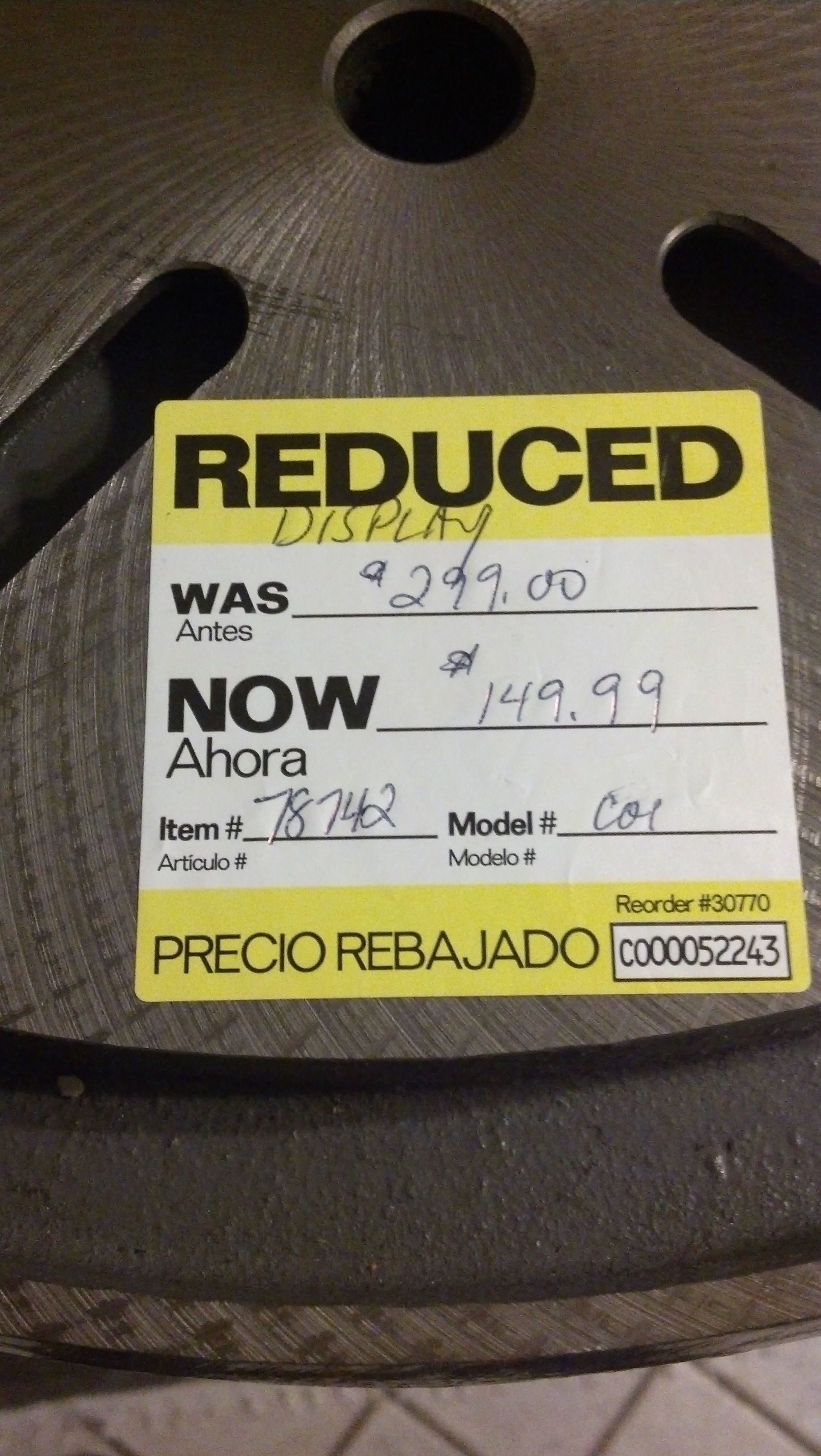

Looking at getting this lathe. Mostly due to having a 20% off coupon for HF. Puts the cost to just under $400 (will get it from the local HF, no shipping or sales tax :rockin . Really need to know if this is a good lathe or a total steaming pile of rhino dung.

. Really need to know if this is a good lathe or a total steaming pile of rhino dung.

Looking at getting it this week IF it's worth getting. Otherwise, I'll continue to search for a lathe, that will do what I want (turning small items) at a decent/reasonable rate.

Looking at getting it this week IF it's worth getting. Otherwise, I'll continue to search for a lathe, that will do what I want (turning small items) at a decent/reasonable rate.