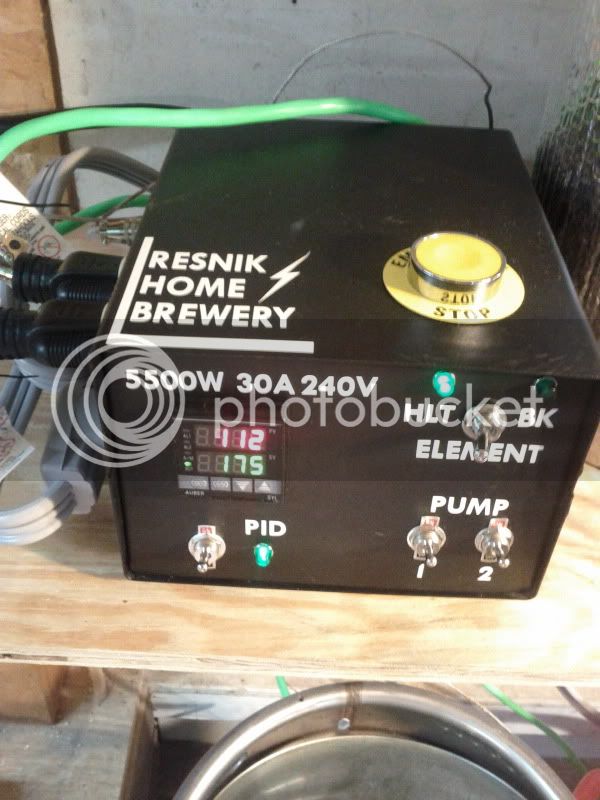

Not sure I could have got much more into this box!

I have upgraded my controller from 120V to 240V and bought a 15 gallon pot and some 5500W elements. These suckers can sure heat up water quick!

Also got a sweet chugger pump which is going to help push my wort through the cfc at a much better rate!

Just about ready for my first 10 gallon batch... :fro:

I have upgraded my controller from 120V to 240V and bought a 15 gallon pot and some 5500W elements. These suckers can sure heat up water quick!

Also got a sweet chugger pump which is going to help push my wort through the cfc at a much better rate!

Just about ready for my first 10 gallon batch... :fro: