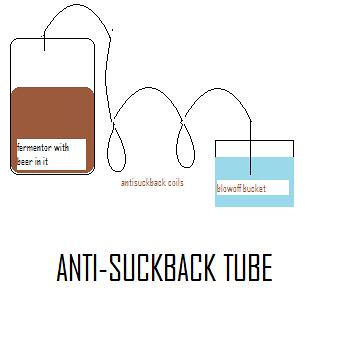

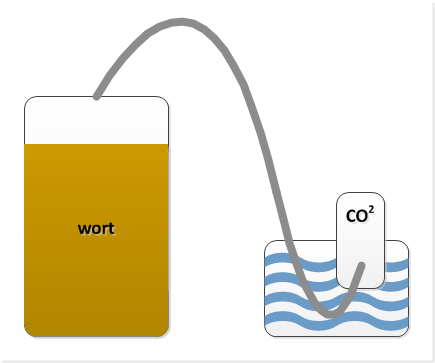

So I was just about to keg my fat tire clone which has been in the primary for 3 weeks. I go to check on it, and somehow it had managed to suck water through the blow off tube and into the carboy!? I have never heard of this happening. It literally sucked nearly half a gallon of water with iodophor in it through the blow off tube! I fear my beer is ruined...

Does anyone know how this could of happened?

Does anyone know how this could of happened?