The Pol

Well-Known Member

- Joined

- Feb 12, 2007

- Messages

- 11,390

- Reaction score

- 117

http://www.livestream.com/brewbeastv21

Water Profile, HERMS water calcs. to come!

Mash Profile:

Water Chart:

Water Profile:

Ca: 88 SO4: 11 Mg: 3 Na: 10 Cl: 2 HCO3: 156 Alky: 240

Buffer 5.2 in mash

A ProMash Brewing Session Report

--------------------------------

Brewing Date: Friday August 07, 2009

Recipe: OktoberFEAST

BJCP Style and Style Guidelines

-------------------------------

03-B European Amber Lager, Oktoberfest/Maerzen

Min OG: 1.050 Max OG: 1.056

Min IBU: 20 Max IBU: 28

Min Clr: 7 Max Clr: 14 Color in SRM, Lovibond

Recipe Specifics

----------------

Batch Size (Gal): 5.50 Wort Size (Gal): 5.50

Total Grain (Lbs): 10.52

Anticipated OG: 1.056 Plato: 13.89

Anticipated SRM: 14.0

Anticipated IBU: 23.3

Brewhouse Efficiency: 82 %

Wort Boil Time: 100 Minutes

Actual OG: 1.056 Plato: 13.80

Actual FG: 1.015 Plato: 3.83

Alc by Weight: 4.21 by Volume: 5.41 From Measured Gravities.

ADF: 72.3 RDF 60.4 Apparent & Real Degree of Fermentation.

Actual Mash System Efficiency: 81 %

Anticipated Points From Mash: 56.39

Actual Points From Mash: 56.00

Pre-Boil Amounts

----------------

Evaporation Rate: 1.50 Gallons Per Hour

Raw Pre-Boil Amounts - only targeted volume/gravity and evaporation

rate taken into account:

Pre-Boil Wort Size: 8.00 Gal

Pre-Boil Gravity: 1.039 SG 9.69 Plato

With sparge water, mash water, additional infusions, vessel losses, top-up

water and evaporation rate recorded in the Water Needed Calculator:

Water Needed Pre-Boil Wort Size: 8.00 Gal

Water Needed Pre-Boil Gravity: 1.039 SG 9.70 Plato

Formulas Used

-------------

Brewhouse Efficiency and Predicted Gravity based on Method #1, Potential Used.

Final Gravity Calculation Based on Points.

Hard Value of Sucrose applied. Value for recipe: 46.2100 ppppg

Yield Type used in Gravity Prediction: Fine Grind Dry Basis.

Color Formula Used: Morey

Hop IBU Formula Used: Tinseth

Tinseth Concentration Factor: 1.30

Additional Utilization Used For Plug Hops: 2 %

Additional Utilization Used For Pellet Hops: 10 %

Grain/Extract/Sugar

% Amount Name Origin Potential SRM

-----------------------------------------------------------------------------

37.0 3.89 lbs. Pilsener Belgium 1.037 2

19.6 2.06 lbs. Vienna Malt Germany 1.037 3

17.4 1.83 lbs. Munich Malt(dark) Canada 1.034 20

8.7 0.91 lbs. Aromatic Malt Belgium 1.036 25

8.7 0.91 lbs. Crystal 20L America 1.035 20

8.7 0.91 lbs. Crystal 45L America 1.034 45

Potential represented as SG per pound per gallon.

Hops

Amount Name Form Alpha IBU Boil Time

-----------------------------------------------------------------------------

1.00 oz. Tettnanger Tettnang Pellet 3.30 13.1 100 min.

0.50 oz. Tettnanger Tettnang Pellet 3.30 5.6 45 min.

0.50 oz. Tettnanger Tettnang Pellet 3.30 4.7 30 min.

Yeast

-----

DCL Yeast S-04 SafAle English Ale

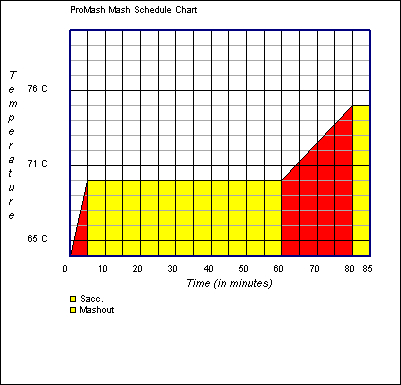

Mash Schedule

-------------

Mash Name:

Total Grain Lbs: 10.52

Total Water Qts: 21.04 - Before Additional Infusions

Total Water Gal: 5.26 - Before Additional Infusions

Tun Thermal Mass: 0.00

Grain Temp: 68 F

Step Rest Start Stop Heat Infuse Infuse Infuse

Step Name Time Time Temp Temp Type Temp Amount Ratio

---------------------------------------------------------------------------------

Sacc. 5 55 158 158 Infuse 166 21.04 2.00

Mashout 20 25 168 168 Direct --- ------- ----

Total Water Qts: 21.04 - After Additional Infusions

Total Water Gal: 5.26 - After Additional Infusions

Total Mash Volume Gal: 6.10 - After Additional Infusions

All temperature measurements are degrees Fahrenheit.

All infusion amounts are in Quarts.

All infusion ratios are Quarts/Lbs.

Water Needed For Brewing Session

--------------------------------

Sparge Amount: 5.50 Sparge Deadspace: 0.00 Total Into Mash: 5.50

Total Grain Lbs: 10.52 Qts Per Lbs: 2.00 Total From Mash: 4.00

Mash Gallons: 5.26

Grain Absorption: 1.26

Amount Lost in Lauter Tun Deadspace,

Grant and Misc. to Kettle: 1.50

Top Up Water Added to Kettle: 0.00

Amount into Kettle: 8.00

Boil Time (min): 100.00 Evaporation Rate: 1.50

Amount after Boil: 5.50

Left in Kettle Deadspace: 0.30

Left in Hopback: 0.00

Left in Counterflow Chiller: 0.00

Left in Other Equipment / Other Absorption: 0.00

Amount to Chillers: 5.20

Amount After Cooling (4 perc.): 4.99

Grain absorption rate is: 0.12 (Gallons Per Lbs)

Evaporation rate is Gallons Per Hour

This formulation will yield 4.99 gallons of fermentable wort.

You will need 10.76 gallons of water for the complete brewing session.

Efficiency Specifics

--------------------

Recipe Efficiency Setting: 82 %

With sparge water, mash water, additional infusions, vessel losses, top-up

water and evaporation rate recorded in the Water Needed Calculator:

Target Volume (Gal): 8.00

Estimated OG: 1.039 Plato: 9.70

Raw Pre-Boil Targets - only targeted volume/gravity and evaporation

rate taken into account:

Target Volume (Gal): 8.00

Estimated OG: 1.039 Plato: 9.69

Post-Boil Targets:

Target Volume (Gal): 5.50

Estimated OG: 1.056 Plato: 13.89

Recorded Actuals - Measurement Taken In Kettle:

Recorded Volume (Gal): 5.50

Recorded OG: 1.056 Plato: 13.80

At 100 percent extraction from the maximum mash potential:

Total Points: 68.76

Points From Mash: 68.76

Points From Extract/Sugar: 0.00

With the recipe efficiency setting, you should have achieved:

Total Points: 56.39

Points From Mash: 56.39

Points From Extract/Sugar: 0.00

Actuals achieved were:

Actual Points From Mash: 56.00

Actual Mash System Efficiency: 81

Fermentation Specifics

----------------------

Pitched From: Starter

Amount Pitched: 10 mL

Lag Time: 24.00 hours

Primary Fermenter: Plastic

Primary Type: Closed

Days In Primary: 14

Primary Temperature: 65 degrees F

Secondary Fermenter: Stainless Steel

Secondary Type: Closed

Days In Secondary: 28

Secondary Temperature: 65 degrees F

Original Gravity: 1.056 SG 13.80 Plato

Finishing Gravity: 1.015 SG 3.83 Plato

Bottling/Kegging Specifics

--------------------------

Bottling Date: Thursday September 17, 2009

Desired Carbonation Level: 2.30 Volumes CO2

Fermentation Temperature: 65 F

Amount Kegged: 5.00 Gallons

Days Conditioned: 0

Carbonation Method: Forced

Carbonation Temperature: 38 F

Pressure Used: 9.15 Psi

Inventory Analysis

------------------

Grain/Malt/Extract/Sugar Origin Recipe Lbs Lbs In Stock Lbs Needed

--------------------------------------------------------------------------------------

Pilsener Belgium 3.89 4.50 0.00

Vienna Malt Germany 2.06 4.75 0.00

Munich Malt(dark) Canada 1.83 6.00 0.00

Aromatic Malt Belgium 0.91 1.00 0.00

Crystal 20L America 0.91 1.50 0.00

Crystal 45L America 0.91 4.00 0.00

Hop Origin Recipe Oz Oz In Stock Oz Needed

------------------------------------------------------------------------------------

Tettnanger Tettnang - Pellet Germany 1.00 4.60 0.00

Tettnanger Tettnang - Pellet Germany 0.50 3.60 0.00

Tettnanger Tettnang - Pellet Germany 0.50 3.10 0.00

Extras Recipe In Stock Needed

-------------------------------------------------------

Yeast Recipe In Stock Needed

-------------------------------------------------------

SafAle English Ale 1.00 2.00 0.00

(DCL Yeast S-04)

Water Profile, HERMS water calcs. to come!

Mash Profile:

Water Chart:

Water Profile:

Ca: 88 SO4: 11 Mg: 3 Na: 10 Cl: 2 HCO3: 156 Alky: 240

Buffer 5.2 in mash

A ProMash Brewing Session Report

--------------------------------

Brewing Date: Friday August 07, 2009

Recipe: OktoberFEAST

BJCP Style and Style Guidelines

-------------------------------

03-B European Amber Lager, Oktoberfest/Maerzen

Min OG: 1.050 Max OG: 1.056

Min IBU: 20 Max IBU: 28

Min Clr: 7 Max Clr: 14 Color in SRM, Lovibond

Recipe Specifics

----------------

Batch Size (Gal): 5.50 Wort Size (Gal): 5.50

Total Grain (Lbs): 10.52

Anticipated OG: 1.056 Plato: 13.89

Anticipated SRM: 14.0

Anticipated IBU: 23.3

Brewhouse Efficiency: 82 %

Wort Boil Time: 100 Minutes

Actual OG: 1.056 Plato: 13.80

Actual FG: 1.015 Plato: 3.83

Alc by Weight: 4.21 by Volume: 5.41 From Measured Gravities.

ADF: 72.3 RDF 60.4 Apparent & Real Degree of Fermentation.

Actual Mash System Efficiency: 81 %

Anticipated Points From Mash: 56.39

Actual Points From Mash: 56.00

Pre-Boil Amounts

----------------

Evaporation Rate: 1.50 Gallons Per Hour

Raw Pre-Boil Amounts - only targeted volume/gravity and evaporation

rate taken into account:

Pre-Boil Wort Size: 8.00 Gal

Pre-Boil Gravity: 1.039 SG 9.69 Plato

With sparge water, mash water, additional infusions, vessel losses, top-up

water and evaporation rate recorded in the Water Needed Calculator:

Water Needed Pre-Boil Wort Size: 8.00 Gal

Water Needed Pre-Boil Gravity: 1.039 SG 9.70 Plato

Formulas Used

-------------

Brewhouse Efficiency and Predicted Gravity based on Method #1, Potential Used.

Final Gravity Calculation Based on Points.

Hard Value of Sucrose applied. Value for recipe: 46.2100 ppppg

Yield Type used in Gravity Prediction: Fine Grind Dry Basis.

Color Formula Used: Morey

Hop IBU Formula Used: Tinseth

Tinseth Concentration Factor: 1.30

Additional Utilization Used For Plug Hops: 2 %

Additional Utilization Used For Pellet Hops: 10 %

Grain/Extract/Sugar

% Amount Name Origin Potential SRM

-----------------------------------------------------------------------------

37.0 3.89 lbs. Pilsener Belgium 1.037 2

19.6 2.06 lbs. Vienna Malt Germany 1.037 3

17.4 1.83 lbs. Munich Malt(dark) Canada 1.034 20

8.7 0.91 lbs. Aromatic Malt Belgium 1.036 25

8.7 0.91 lbs. Crystal 20L America 1.035 20

8.7 0.91 lbs. Crystal 45L America 1.034 45

Potential represented as SG per pound per gallon.

Hops

Amount Name Form Alpha IBU Boil Time

-----------------------------------------------------------------------------

1.00 oz. Tettnanger Tettnang Pellet 3.30 13.1 100 min.

0.50 oz. Tettnanger Tettnang Pellet 3.30 5.6 45 min.

0.50 oz. Tettnanger Tettnang Pellet 3.30 4.7 30 min.

Yeast

-----

DCL Yeast S-04 SafAle English Ale

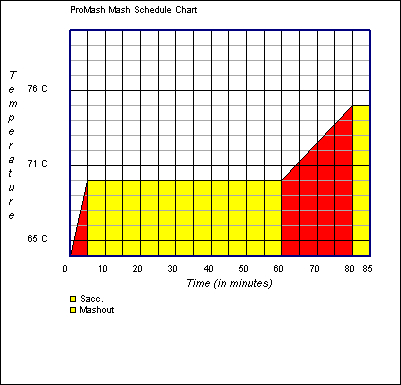

Mash Schedule

-------------

Mash Name:

Total Grain Lbs: 10.52

Total Water Qts: 21.04 - Before Additional Infusions

Total Water Gal: 5.26 - Before Additional Infusions

Tun Thermal Mass: 0.00

Grain Temp: 68 F

Step Rest Start Stop Heat Infuse Infuse Infuse

Step Name Time Time Temp Temp Type Temp Amount Ratio

---------------------------------------------------------------------------------

Sacc. 5 55 158 158 Infuse 166 21.04 2.00

Mashout 20 25 168 168 Direct --- ------- ----

Total Water Qts: 21.04 - After Additional Infusions

Total Water Gal: 5.26 - After Additional Infusions

Total Mash Volume Gal: 6.10 - After Additional Infusions

All temperature measurements are degrees Fahrenheit.

All infusion amounts are in Quarts.

All infusion ratios are Quarts/Lbs.

Water Needed For Brewing Session

--------------------------------

Sparge Amount: 5.50 Sparge Deadspace: 0.00 Total Into Mash: 5.50

Total Grain Lbs: 10.52 Qts Per Lbs: 2.00 Total From Mash: 4.00

Mash Gallons: 5.26

Grain Absorption: 1.26

Amount Lost in Lauter Tun Deadspace,

Grant and Misc. to Kettle: 1.50

Top Up Water Added to Kettle: 0.00

Amount into Kettle: 8.00

Boil Time (min): 100.00 Evaporation Rate: 1.50

Amount after Boil: 5.50

Left in Kettle Deadspace: 0.30

Left in Hopback: 0.00

Left in Counterflow Chiller: 0.00

Left in Other Equipment / Other Absorption: 0.00

Amount to Chillers: 5.20

Amount After Cooling (4 perc.): 4.99

Grain absorption rate is: 0.12 (Gallons Per Lbs)

Evaporation rate is Gallons Per Hour

This formulation will yield 4.99 gallons of fermentable wort.

You will need 10.76 gallons of water for the complete brewing session.

Efficiency Specifics

--------------------

Recipe Efficiency Setting: 82 %

With sparge water, mash water, additional infusions, vessel losses, top-up

water and evaporation rate recorded in the Water Needed Calculator:

Target Volume (Gal): 8.00

Estimated OG: 1.039 Plato: 9.70

Raw Pre-Boil Targets - only targeted volume/gravity and evaporation

rate taken into account:

Target Volume (Gal): 8.00

Estimated OG: 1.039 Plato: 9.69

Post-Boil Targets:

Target Volume (Gal): 5.50

Estimated OG: 1.056 Plato: 13.89

Recorded Actuals - Measurement Taken In Kettle:

Recorded Volume (Gal): 5.50

Recorded OG: 1.056 Plato: 13.80

At 100 percent extraction from the maximum mash potential:

Total Points: 68.76

Points From Mash: 68.76

Points From Extract/Sugar: 0.00

With the recipe efficiency setting, you should have achieved:

Total Points: 56.39

Points From Mash: 56.39

Points From Extract/Sugar: 0.00

Actuals achieved were:

Actual Points From Mash: 56.00

Actual Mash System Efficiency: 81

Fermentation Specifics

----------------------

Pitched From: Starter

Amount Pitched: 10 mL

Lag Time: 24.00 hours

Primary Fermenter: Plastic

Primary Type: Closed

Days In Primary: 14

Primary Temperature: 65 degrees F

Secondary Fermenter: Stainless Steel

Secondary Type: Closed

Days In Secondary: 28

Secondary Temperature: 65 degrees F

Original Gravity: 1.056 SG 13.80 Plato

Finishing Gravity: 1.015 SG 3.83 Plato

Bottling/Kegging Specifics

--------------------------

Bottling Date: Thursday September 17, 2009

Desired Carbonation Level: 2.30 Volumes CO2

Fermentation Temperature: 65 F

Amount Kegged: 5.00 Gallons

Days Conditioned: 0

Carbonation Method: Forced

Carbonation Temperature: 38 F

Pressure Used: 9.15 Psi

Inventory Analysis

------------------

Grain/Malt/Extract/Sugar Origin Recipe Lbs Lbs In Stock Lbs Needed

--------------------------------------------------------------------------------------

Pilsener Belgium 3.89 4.50 0.00

Vienna Malt Germany 2.06 4.75 0.00

Munich Malt(dark) Canada 1.83 6.00 0.00

Aromatic Malt Belgium 0.91 1.00 0.00

Crystal 20L America 0.91 1.50 0.00

Crystal 45L America 0.91 4.00 0.00

Hop Origin Recipe Oz Oz In Stock Oz Needed

------------------------------------------------------------------------------------

Tettnanger Tettnang - Pellet Germany 1.00 4.60 0.00

Tettnanger Tettnang - Pellet Germany 0.50 3.60 0.00

Tettnanger Tettnang - Pellet Germany 0.50 3.10 0.00

Extras Recipe In Stock Needed

-------------------------------------------------------

Yeast Recipe In Stock Needed

-------------------------------------------------------

SafAle English Ale 1.00 2.00 0.00

(DCL Yeast S-04)