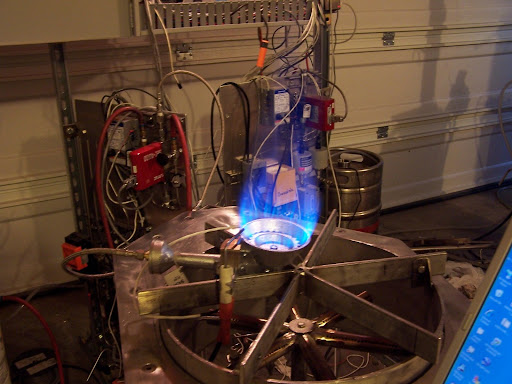

Here is a shot of brewing hardware without boiler, grain hopper, mill, and plc panel are in their final location.http://picasaweb.google.com/kevin.ladue/BreweryConstructionProgress/photo#5183730230813303522

Still have internals and drive motor to install on screw conveyor then after boiler heat sheild and mounting hardware installed, everything gets pulled off the walls for insulation and sheetrock installation.

Still have internals and drive motor to install on screw conveyor then after boiler heat sheild and mounting hardware installed, everything gets pulled off the walls for insulation and sheetrock installation.