Hi there.

I just went to my local store (Canadian Tire) and they had 2 left on sale - from $99.99 downl to $24.99 - one of the boxes was opened, and missing the lid.

I got both and am trying right now to see how this thing heats up.

So far, it looks like average. I am heating 20liters (about 5 gal I believe) of whater, and without the lid, it is almost at strike temperature (165 deg F) afte one hour. I purposely made it without the lid to test things in the worst situations. I will also try isolating the aluminum pot cause I believe this is one of the places it looses a lot of heat.

Overall, the things is quite well done. I particularely like the spigot at the bottom, which I don't have in my other 34 qts kettle. I will let it go to see how long it can get to a rolling boil with that quantity of water. Naturally, the hot liquor will be more than my starting 64 deg. F, so I expect a better time ratio. Also, I plan to put the lid on while it heats, only removing it when it boils.

The advantages for me are that I can brew during winter in my basement (I don't have a garage).

Also, there is a dial to set the temperature, so I can probably keep a temperature (roughly since it is not digital) which is hard to do on my stove top or on my propane burner.

I can use a regular 120v outlet - no need to wire something special.

And lastly, if this is too long, I will use the element from the second one I got to speed things up - actually, this is the main reason I got the last two

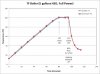

Here is the temperature over time so far :

0 min - 64 F

15 min - 88 F

20 min - 97 F

25 min - 106 F

30 min - 114 F

35 min - 124 F

40 min - 131 F (got tired and put on the lid :s)

45 min - 140 F

50 min - 148 F

55 min - 156 F

60 min - 165 F (I normaly aim for 164 F for my initial water temp in my mash tun)

65 min - 173 F

70 min - 181 F

75 min - 187 F

80 min - 193 F

85 min - 201 F

90 min - 206 F

95 min - 210 F

99 min - 212 F

At this point, I had a good start of a boil, and i kept it for about 10 minutes without the lid to see how it would behave. the boil went on increasing even without the lid, so yes it can keep boiling.

Please keep in mind that this was a total of 20 liters, startin at 64 F. Not the normal qty of water you start off for a 5 gal batch.

Hope this helps someone!

Zolt