d_ozz68

Well-Known Member

Hi all....

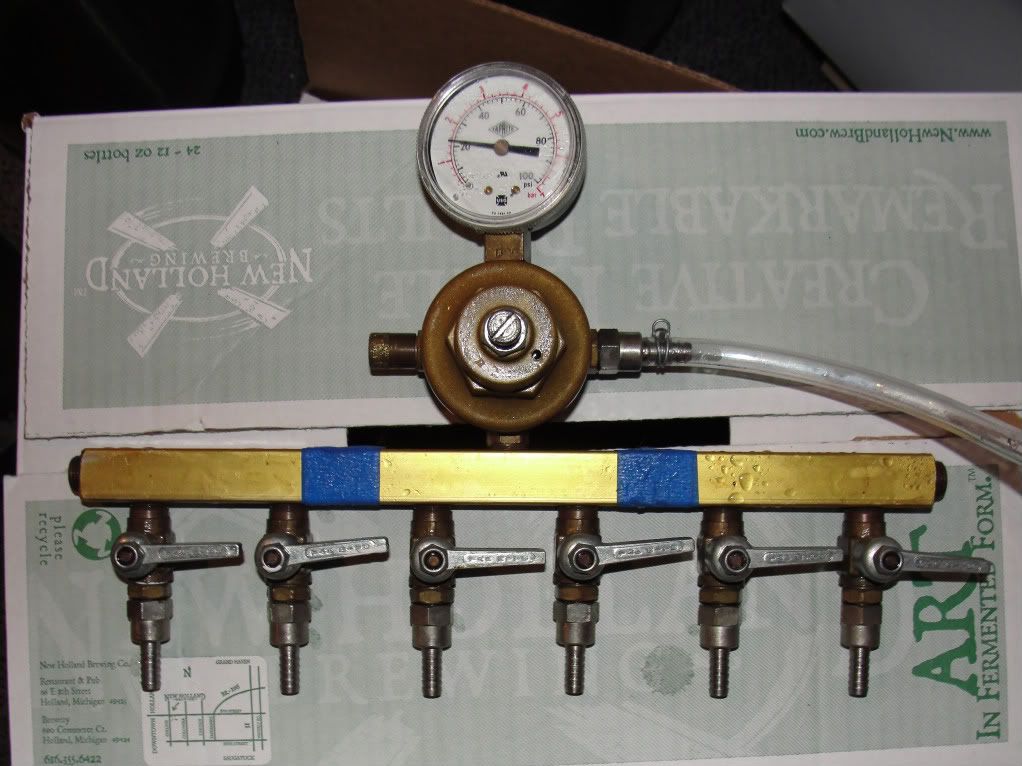

I have a secondary regulator that is screwed in directly to a 6 way manifold that appears to have a very slow leak. I hit it with 30psi and then turned the gas off and the pressure has now dropped to 28psi after about 2 hours. I have the manifold submerged in water and have not seen a single air bubble.

My question is, does anyone know if this amount of loss is acceptable or do I need to keep hunting for the leak and maybe consider that I might have a bad regulator?

Also, I don't know if this will change anything however when I plan on using this manifold the Co2 coming in will be at 30psi (because of my keg of root beer) but I will have the regulator on the manifold set at around 8-10 psi for dispensing my beer so maybe the leak will be slower.?.?

Any comments/advice will be greatly appreciated!! Thanks!!

I have a secondary regulator that is screwed in directly to a 6 way manifold that appears to have a very slow leak. I hit it with 30psi and then turned the gas off and the pressure has now dropped to 28psi after about 2 hours. I have the manifold submerged in water and have not seen a single air bubble.

My question is, does anyone know if this amount of loss is acceptable or do I need to keep hunting for the leak and maybe consider that I might have a bad regulator?

Also, I don't know if this will change anything however when I plan on using this manifold the Co2 coming in will be at 30psi (because of my keg of root beer) but I will have the regulator on the manifold set at around 8-10 psi for dispensing my beer so maybe the leak will be slower.?.?

Any comments/advice will be greatly appreciated!! Thanks!!