Tripod

Well-Known Member

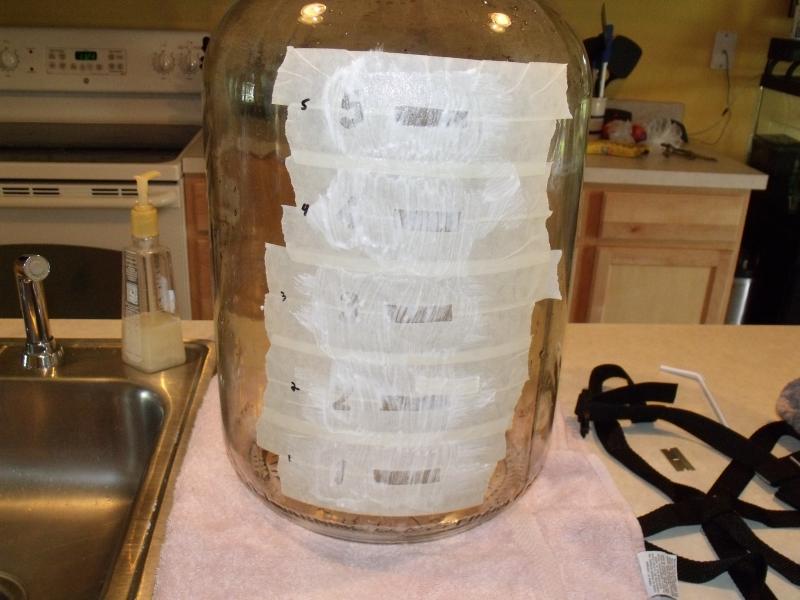

Hate to bring up an older thread but wanted to say thanks.. I seen this and had to give it a try. This is what I ended up with.

Cool design! I like the way you marked yours although it took me a moment to realize which marks were for full gallons and which were for halves...

-Tripod