This thread inspired me to try my hand at this.

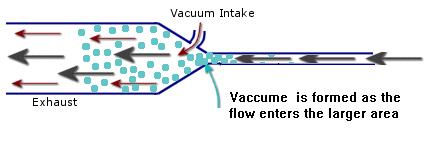

It relies on the Venturi affect to introduce air into the wort flow. For those not familiar, the Venturi effect is the increase in velocity and corresponding decrease in pressure that results when a fluid flows through a constricted section of pipe. A venturi injector has an inlet at the site of the constriction. As a result of the low pressure the fluid passing by the hole creates a vacuum and pulls in another fluid. In this case the passing wort draws in air.

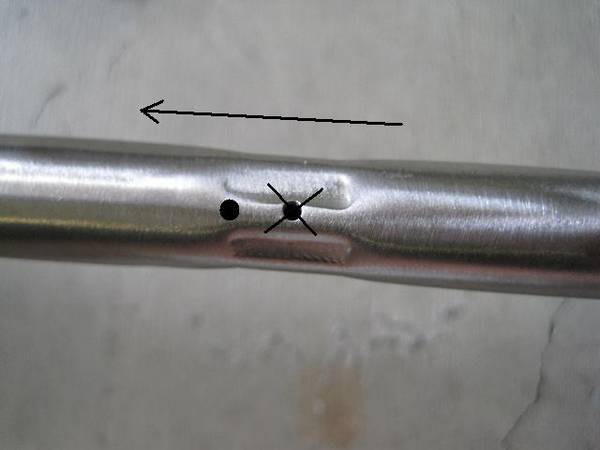

In the referenced thread, the constriction was caused by placing a smaller diameter tube inline with the output from the boil kettle. This seemed to work well, but I wanted a device that was one-piece, easy to attach and stainless steel. I decided to crimp a section tubing to make the restriction. I tested it on a small piece of soft copper. Using the two halves of a flaring tool, I placed the tubing in the flaring tool registry that was one unit smaller than the OD of the tubing (i.e. 1/2" OD tubing in 3/8" flaring registry). Then placed the assembly in a vise and crimped it.

I then drilled a hole at the restriction and tested. It took a few tries to get the hole placement right to yeild the most amount of bubbles. I then moved to 1/2" stainless tubing, brazed on a 1-1/2" tri-clamp fitting. It works really well. I'll post some pics of it in action when I brew on Saturday.

The aerator wand is placed into fermenter. I pass the wort through the plate chiller, through the aerator and directly into the fermenter. I have tested it with a March 809 pump at full throttle and it worked flawlessly. The restriction didn't cause a noticeable reduction in flow rate.

It relies on the Venturi affect to introduce air into the wort flow. For those not familiar, the Venturi effect is the increase in velocity and corresponding decrease in pressure that results when a fluid flows through a constricted section of pipe. A venturi injector has an inlet at the site of the constriction. As a result of the low pressure the fluid passing by the hole creates a vacuum and pulls in another fluid. In this case the passing wort draws in air.

In the referenced thread, the constriction was caused by placing a smaller diameter tube inline with the output from the boil kettle. This seemed to work well, but I wanted a device that was one-piece, easy to attach and stainless steel. I decided to crimp a section tubing to make the restriction. I tested it on a small piece of soft copper. Using the two halves of a flaring tool, I placed the tubing in the flaring tool registry that was one unit smaller than the OD of the tubing (i.e. 1/2" OD tubing in 3/8" flaring registry). Then placed the assembly in a vise and crimped it.

I then drilled a hole at the restriction and tested. It took a few tries to get the hole placement right to yeild the most amount of bubbles. I then moved to 1/2" stainless tubing, brazed on a 1-1/2" tri-clamp fitting. It works really well. I'll post some pics of it in action when I brew on Saturday.

The aerator wand is placed into fermenter. I pass the wort through the plate chiller, through the aerator and directly into the fermenter. I have tested it with a March 809 pump at full throttle and it worked flawlessly. The restriction didn't cause a noticeable reduction in flow rate.