BoomerHarley

Well-Known Member

I brew in a 14.5 gallon conical inside a stand up freezer. Recently I put a thermowell on it and the probe reads from the center of the fermenting beer.

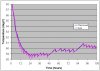

However, the last two batches (since the change) have both ended up not fermenting out and being very sweet (1.020 or so). Watching a digital temp probe I have inside the freezer I notice that now the temps range from 70 or so down to 34 degrees and I think I may be causing more of a problem than anything.

My assumption is that it takes so long for the thermowell to register a change in heat, that I am practically freezing the wort and yeast near the edges. Previous to the change, my fridge pretty much went on for a few minutes to drop the temp at the ambient probe, then turned off (vice versa for heat). Now it cycles very cold and was very hot but I replaced the room heater (cycled at 112-34 degrees) to an aquarium bukb (cycles from 75-34).

Any thoughts? At this point, I think the thermowell is not helping.

P.S. I searched and found 134375389339292 thread on thermowells, none of which seemed to address this issue.

However, the last two batches (since the change) have both ended up not fermenting out and being very sweet (1.020 or so). Watching a digital temp probe I have inside the freezer I notice that now the temps range from 70 or so down to 34 degrees and I think I may be causing more of a problem than anything.

My assumption is that it takes so long for the thermowell to register a change in heat, that I am practically freezing the wort and yeast near the edges. Previous to the change, my fridge pretty much went on for a few minutes to drop the temp at the ambient probe, then turned off (vice versa for heat). Now it cycles very cold and was very hot but I replaced the room heater (cycled at 112-34 degrees) to an aquarium bukb (cycles from 75-34).

Any thoughts? At this point, I think the thermowell is not helping.

P.S. I searched and found 134375389339292 thread on thermowells, none of which seemed to address this issue.