Boerderij_Kabouter

Well-Known Member

Thanks!

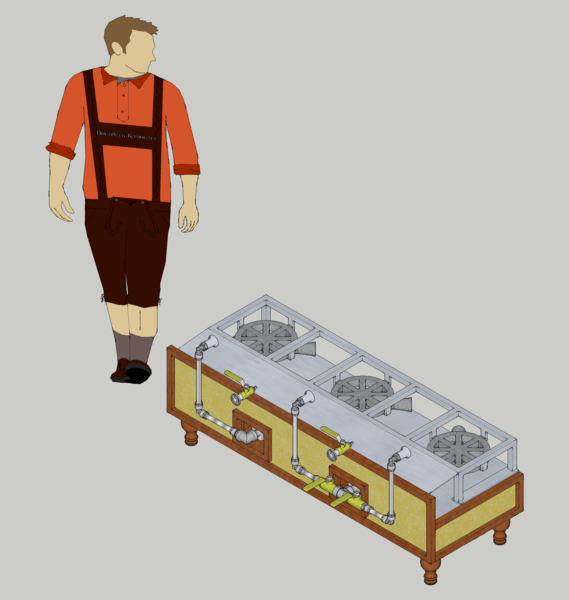

The connectors are called Tri-clover or tri-clamp fittings. They are standard in professional food processing and and brewing.

They include a gasket and a clamp that compresses the gasket between the two fittings.

The advantage over regular QD's is that the are bomb proof with no moving parts, and are very easy to clean/sanitize.

I just had my first brew day with them and could not be happier.

The connectors are called Tri-clover or tri-clamp fittings. They are standard in professional food processing and and brewing.

They include a gasket and a clamp that compresses the gasket between the two fittings.

The advantage over regular QD's is that the are bomb proof with no moving parts, and are very easy to clean/sanitize.

I just had my first brew day with them and could not be happier.