Hoosierbilly

Well-Known Member

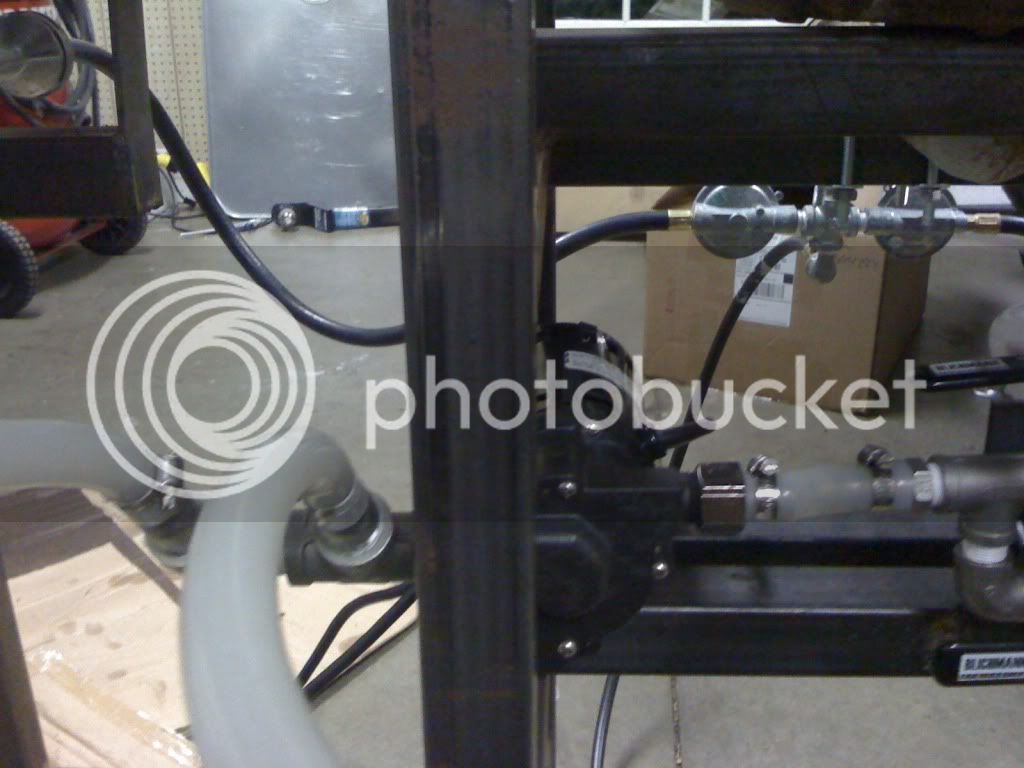

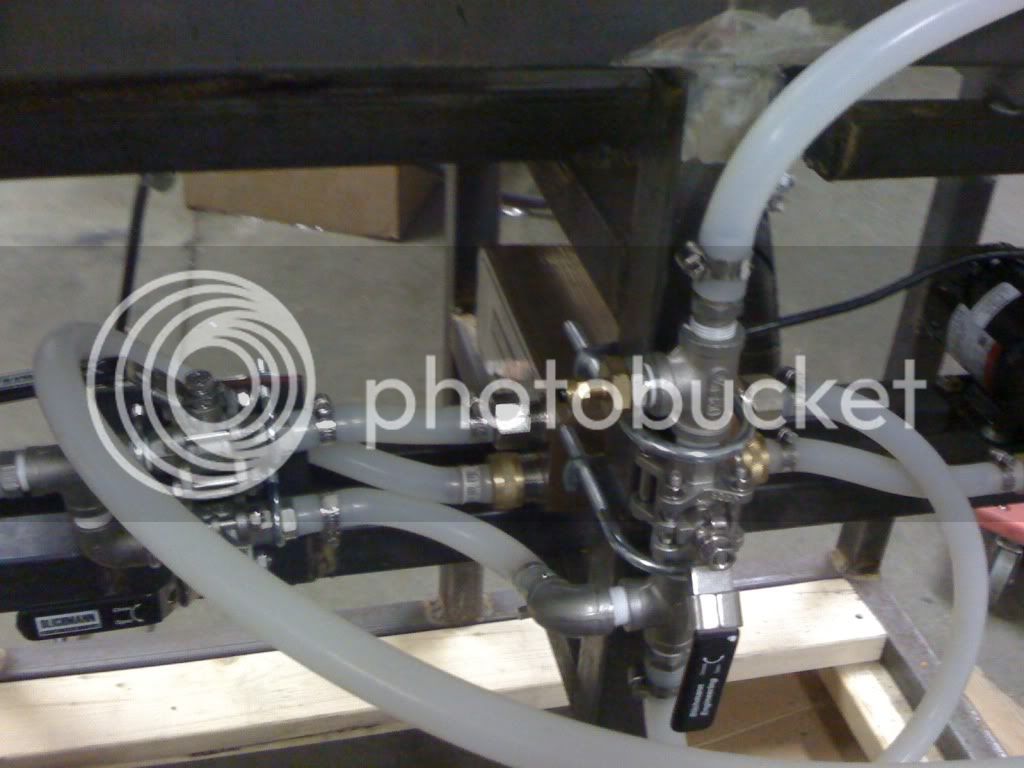

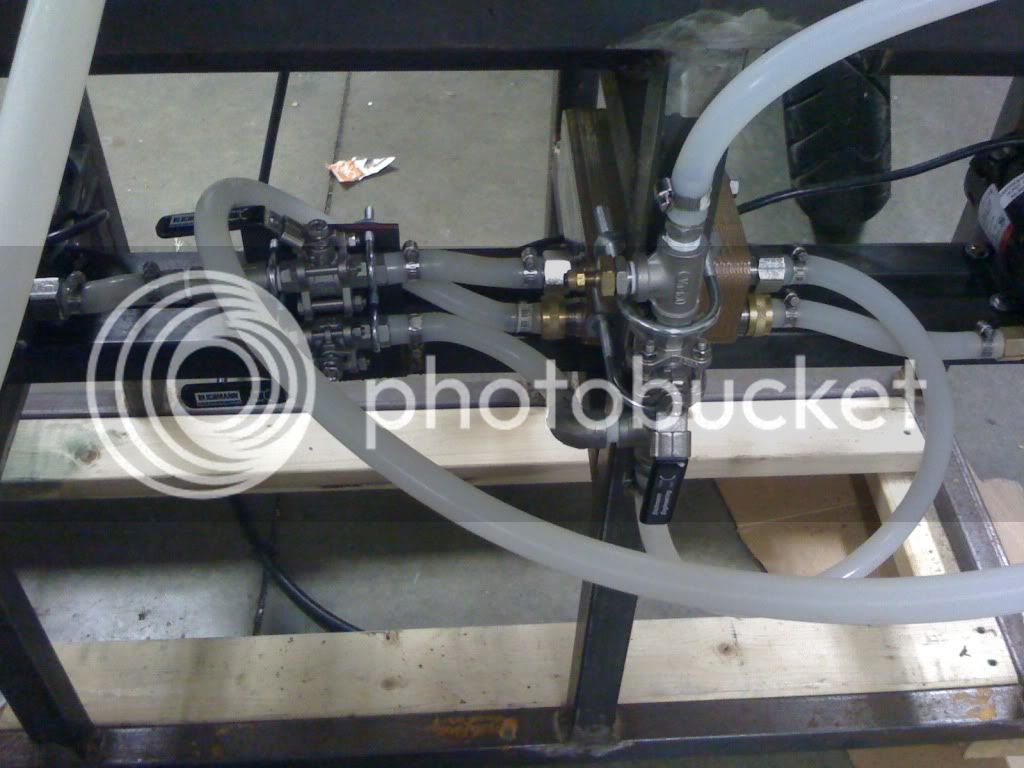

After searching around, I only found people asking questions about whether or not the blichmann therminator will work as a heat exchanger for a herms system so im going to try it...and i like doing things differently I guess. So i have 1 pump circulating the wort constantly, and the other pump will pump heated water through the heat exchanger when the wort temp gets down to a certain point...im not sure what temp im going to have the hot water at for adding heat to the wort, but the plan is to have 1 pump constantly recirculating the wort, and one pump for the hot water into the thermintor turn on and off as needed

Just got by BCS-460 in yesterday, ordered 2 brew-magic universal kettles today, and my brew-magic fermentor should be here anyday!

I havent seen anyone else doing this so i thought id just try it out and let anyone who was wondering know how it works out...ill post some pictures in just a bit...

Just got by BCS-460 in yesterday, ordered 2 brew-magic universal kettles today, and my brew-magic fermentor should be here anyday!

I havent seen anyone else doing this so i thought id just try it out and let anyone who was wondering know how it works out...ill post some pictures in just a bit...