BrotherGrim

Well-Known Member

- Joined

- Jun 19, 2012

- Messages

- 351

- Reaction score

- 84

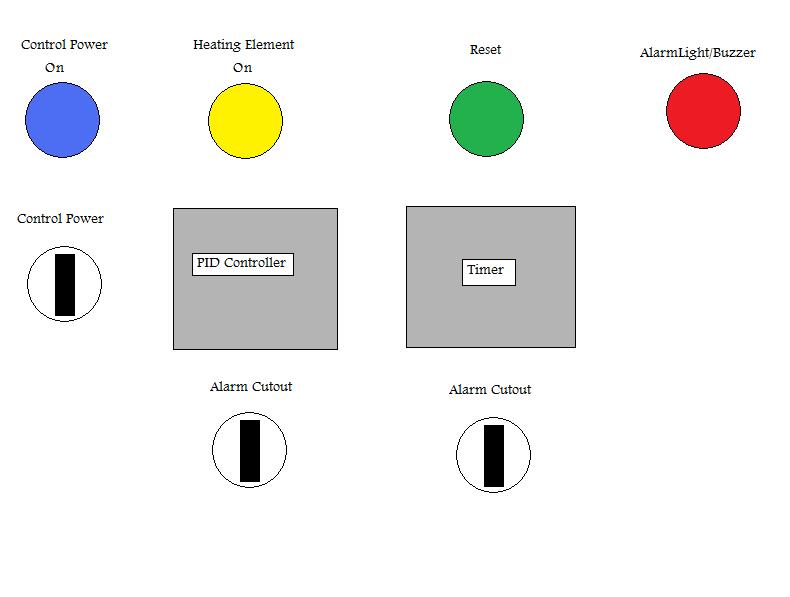

I am getting ready to start a build on an Electric brew kettle for BIAB setup. I have a Blichmann 10 gal kettle with the false bottom on the way, and I am planning on installing a 5500W ULWD heater under the false bottom. The plan is to put together a PID controller with SSR to run the heater allowing me to set my mash temp, then raise temp to boil after the bag is pulled. Planning on a timer unit in the controller as well, essentially a smaller version of the Electric Brewery Controller. They have an awesome setup, but it doesn't fit my reduced equipment desires. I plan on documenting and posting the build if it will come together the way I am envisioning it.

Any thoughts?

Any thoughts?