Even with a tight lid gasket and silicone sealant closing up the holes for the CO2 and the 12 volt feed to my tower cooler, when the humid season arrives my 10cf keezer is afflicted with puddled condensation that's a pita to mop up every few weeks. So I had picked up one of the popular Eva-Dry E-500 "dehumidifiers" in the hope that it would suck up the humidity.

I had emptied the keezer of all six kegs, dried it out to the proverbial bone, then reloaded it and set the E-500 in the middle of the keezer floor. But after just two weeks of use it was clear that it simply didn't work much if at all. The indicator showed the same blue color as it had when I took it out of the sealed package, and there were puddles beginning to form again.

After thinking a bit about this a bit, and realizing there was virtually no air movement within the keezer, I decided it would be worth a simple hack to see if I could improve the performance of the little beast by forcing air through it with a small 12v fan I had in my parts bin.

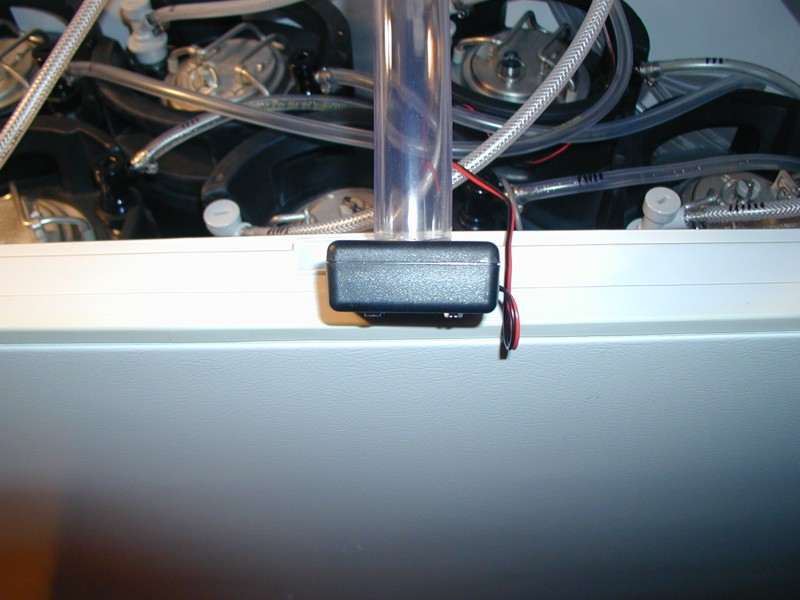

As there's an electric coil within the Eva-Dry that is used to heat up and dry out the desiccant, I didn't want to risk damaging that by driving screws into its case, so I used a piece of Velcro to stick an 80mm fan to one side of the case.

I daisy-chained the fan to the 12V feed to my tower cooler fan, set it back in the middle of the keezer floor, and waited to see what happened.

The result has been amazingly transformative: that 80mm fan really stirs the air inside the keezer and drives it right into the drier, and the keezer has remained puddle-free for three weeks now. As I was drawing a bed-time pint of my favorite Imperial Stout tonight I checked the indicator on the Eva-Dry and it was definitely turning pink, indicating it was doing its job.

So I figured I'd run the overnight drying cycle on it and take a couple of pics to post up here, in case anyone else has had a less than impressive experience with these little guys. A simple fan turned what was essentially a brick into something very useful indeed...

Cheers!

I had emptied the keezer of all six kegs, dried it out to the proverbial bone, then reloaded it and set the E-500 in the middle of the keezer floor. But after just two weeks of use it was clear that it simply didn't work much if at all. The indicator showed the same blue color as it had when I took it out of the sealed package, and there were puddles beginning to form again.

After thinking a bit about this a bit, and realizing there was virtually no air movement within the keezer, I decided it would be worth a simple hack to see if I could improve the performance of the little beast by forcing air through it with a small 12v fan I had in my parts bin.

As there's an electric coil within the Eva-Dry that is used to heat up and dry out the desiccant, I didn't want to risk damaging that by driving screws into its case, so I used a piece of Velcro to stick an 80mm fan to one side of the case.

I daisy-chained the fan to the 12V feed to my tower cooler fan, set it back in the middle of the keezer floor, and waited to see what happened.

The result has been amazingly transformative: that 80mm fan really stirs the air inside the keezer and drives it right into the drier, and the keezer has remained puddle-free for three weeks now. As I was drawing a bed-time pint of my favorite Imperial Stout tonight I checked the indicator on the Eva-Dry and it was definitely turning pink, indicating it was doing its job.

So I figured I'd run the overnight drying cycle on it and take a couple of pics to post up here, in case anyone else has had a less than impressive experience with these little guys. A simple fan turned what was essentially a brick into something very useful indeed...

Cheers!