I had an Ausiie suggest reading the head space instead and it made sense. 40 liters to the top of the rod minus 10 cm dow equals 30 liters! Huh I think I will just cut off a yard/meter stick and use the zero to 40 cm marks to measure down.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Speidel Braumeister (brewmaster)

- Thread starter FiveKaiBrewing

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

dinnerstick

Well-Known Member

sometimes the answer is right in front of your face! i like it

goodgodilovebeer

Well-Known Member

I'm getting real close to pulling the trigger on this bad boy!

Has anyone had issues with the pump as mentioned in earlier posts? I'm hoping this has been resolved. Also, nobody's burned down their house yet by hacking the cord I hope.

Has anyone had issues with the pump as mentioned in earlier posts? I'm hoping this has been resolved. Also, nobody's burned down their house yet by hacking the cord I hope.

dinnerstick

Well-Known Member

bcryan- !! are you very thirsty or running a brewpub?? more information required! i'm just about at the first birthday of my machine, with maybe 20 brews done and various other uses (sous vide cooker, pasteurization water bath) running the pump. never had an issue with the pump, never even opened it! knock on wood. i have a silicone hose that fits right in the inlet/outlet holes, and i flush it very well in both directions with a lot of hot water, after an oxiclean soak, after each use. now- about to go brew an english brown ale!

goodgodilovebeer

Well-Known Member

Good to know guys. I'm just waiting on a shipping quote from morebeer at this point. I was quoted roughly $2600 (unit, thermo-jacket, & shipping) from our Canadian distributor. Seems abnormally high.

bcryan...? 5/week?!

bcryan...? 5/week?!

wobdee

Junior Member

Could the 20L brew smaller 2.5-3 gal batches? Sorry if this has already been discussed but I couldn't find the answer skimming through the first half of this thread.

I BIAB 2.5 gal batches and usually mash with 4 gal of water and no sparge. After grain absorbsion, boil and trub loss I usually end up with a little over 2.5 gal.

I BIAB 2.5 gal batches and usually mash with 4 gal of water and no sparge. After grain absorbsion, boil and trub loss I usually end up with a little over 2.5 gal.

goodgodilovebeer

Well-Known Member

Lylo, I couldn't wait for morebeer to get them back in stock... I'm mega impatient when it comes to new toys! I ordered from Canadian Homebrew Supplies after speaking with a guy named Randy. I called and he was more than happy to answer a bunch of questions I had, even though I could tell that the shop was teaming with customers in the background. I really appreciate little things like that when it comes to customer service. Within about an hour, I had an email from FedEx regarding the shipment. Pickup from their shop being scheduled for Monday. 3 day was the only option, but I'm ok with that. I've ordered a bunch from morebeer over the past few years, and while I've never had a problem, I decided to throw my cash at our economy (not at all intended to make you feel guilty). Hope there's great beers being brewed up in Lacombe!

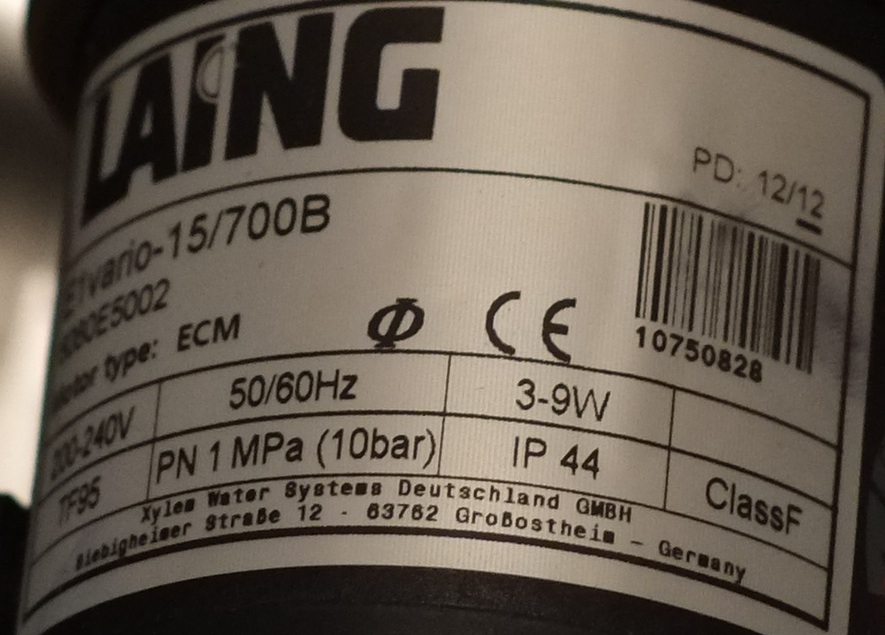

There's been a couple questions about the pump. Here is a close-up of the label.

Jim

I've been following this thread and am very interested in the way the Braumeister works. A 10 Bar pump is very powerful - if I have the conversion right, 10 Bar equates to about 102 meters (or 334.6 feet) of head, or 145 psi.

This is more than 26 times more pressure than the March809, which has 12.1 feet of head, or 5.25 psi.

Is there anything I have wrong here - is it correct that the Braumeister is using a much, much more powerful pump that the March809?

The other question I have is for all Braumeister owners out there. I've seen the video, and it's pretty clear that the very top surface of the grain has been pressing against the 'false' top' in the grain tube. What is not so clear to me is whether the entire grain bed is also getting pressed against the false top during recirculation or not (just a small surface layer).

For those of you that have removed your grain tube and emptied it, is the grain bed compressed into a compact patty or loose? Any other evidence of whether the bulk of the grain is pushing down on the false bottom or pressing up against the false top during recirculation ? Has anyone ever halted recirculation mid-way (for stuck mash or whatever reason), removed the false top and stirred the grain bed? And if so, I would appreciate a description of what the grainbed was like and where it was located - was it compacted (maybe even into a compressed patty) or was it loose? Was it up high near the false top or down low near the false bottom?

I have no idea what is happening to the grainbed inside the mashtube when liquor powered by that powerful of a pump is being forced up into the bottom of the grainbed, and would appreciate any insight the Braumeister owners out there could provide...

thanks,

-fafrd

goodgodilove beer. When I ordered mine from B3 CHS was out of stock as well. I got a message from CHS that they had them back in stock the same day that B3 shipped.

I too would have liked to keep my Cdn$ on this side of the border but for the 500 bills I couldn't see cancelling the US order. I have now done 2 brews with it and am really liking it .I know you will too.

Us Canucks should stay in touch. Are you a Yeast Wrangler?

I too would have liked to keep my Cdn$ on this side of the border but for the 500 bills I couldn't see cancelling the US order. I have now done 2 brews with it and am really liking it .I know you will too.

Us Canucks should stay in touch. Are you a Yeast Wrangler?

psehorne

Well-Known Member

Could the 20L brew smaller 2.5-3 gal batches?

I have found that a minimum of 20L is required to keep the heating coil covered with water when the pump fills the malt pipe to overflowing and leaves little water in the kettle outside of the malt pipe.

Another poster modified his malt pipe with a ring of holes down a few inches from the top to limit how much water is required to fill the malt pipe to overflowing (at this new level). He created a band of some sort to cover the holes when he wants to brew a full batch.

psehorne

Well-Known Member

The other question I have is for all Braumeister owners out there. I've seen the video, and it's pretty clear that the very top surface of the grain has been pressing against the 'false' top' in the grain tube. What is not so clear to me is whether the entire grain bed is also getting pressed against the false top during recirculation or not (just a small surface layer).

The pump pulls water from the port in the bottom of the kettle that is outside of the malt pipe. If forces water up through the port nearer the center of the kettle and up through the malt pipe, pushing the grain bed up. I found the hard way, by failing to answer the prompt after the last mash cycle at the mash-out stage. I removed the hold-down bar while apparently the unit was doing a pump rest and at about the time the pump came on and the whole grain bed began to rise and overflowed the malt pipe before I realized what was happening. Of course I quickly answered the prompt and the pump stopped.

The pump pulls water from the port in the bottom of the kettle that is outside of the malt pipe. If forces water up through the port nearer the center of the kettle and up through the malt pipe, pushing the grain bed up. I found the hard way, by failing to answer the prompt after the last mash cycle at the mash-out stage. I removed the hold-down bar while apparently the unit was doing a pump rest and at about the time the pump came on and the whole grain bed began to rise and overflowed the malt pipe before I realized what was happening. Of course I quickly answered the prompt and the pump stopped.

psehorne,

thanks for the description - so the entire grain bed appeared to be rising up, from the pump flow, not just a small surface layer of grain? I'm trying to get an understanding of whether the Braumeister mashes with the grain bed 'up' or 'down' . When you raise your maltpipe at the end of the mash, do you have any sense of whether you are lifting the entire grain bed from the false bottom up or whether you are just lifting the false bottom up easily until it comes into contact with the bottom of the grain bed where suddenly lifting becomes harder/heavier?

And when you empty your maltpipe, is the grain bed compressed into a compact patty or is it loose?

Thanks for the additional info - it is a mystery to me what happens to the grain bed in these malt tube systems once the pump starts pumping up into them so any observations and inputs from owners is very helpful...

-fafrd

goodgodilovebeer

Well-Known Member

goodgodilove beer. When I ordered mine from B3 CHS was out of stock as well. I got a message from CHS that they had them back in stock the same day that B3 shipped.

I too would have liked to keep my Cdn$ on this side of the border but for the 500 bills I couldn't see cancelling the US order. I have now done 2 brews with it and am really liking it .I know you will too.

Us Canucks should stay in touch. Are you a Yeast Wrangler?

I totally understand. Mine should be shipped from Ontario today and most likely arrive by Thursday according to CHBS. My buddy who's an electrician and works on wind turbines said he's talked to master electricians about the equipment and shouldn't have a problem helping me with the electrical next week. Judging by his conversation with the master electrician, the only concern would be the Hz difference, but that's not a deal breaker. How did your re-wiring of the BM go?

psehorne

Well-Known Member

When you raise your maltpipe at the end of the mash, do you have any sense of whether you are lifting the entire grain bed from the false bottom up or whether you are just lifting the false bottom up easily until it comes into contact with the bottom of the grain bed where suddenly lifting becomes harder/heavier?

And when you empty your maltpipe, is the grain bed compressed into a compact patty or is it loose?

-fafrd

The pump has stopped when you lift the malt pipe and all the grain has settled to the bottom. As you lift the malt pipe you are raising the grain with the false bottom. As you lift it, it is heavy (laden with soaked grain) and the water is falling out the bottom. At the point where the false bottom tries to leave the water there is addition suction causing the malt pipe to be harder to lift, but that is not because the false bottom has just reached the grain. The grain was setting on the false bottom all during your lifting.

You lift the pipe up just a little above the water level in order to hang it by the pegs. At this time the top screens are still in place and sitting on the compressed grain bed. I leave those screens in while I sparge and only remove then after lifting the malt pipe, grain, and screens totally out of the kettle and setting the lot in a picnic cooler (because a bit more water will drain out of the grain).

I totally understand. Mine should be shipped from Ontario today and most likely arrive by Thursday according to CHBS. My buddy who's an electrician and works on wind turbines said he's talked to master electricians about the equipment and shouldn't have a problem helping me with the electrical next week. Judging by his conversation with the master electrician, the only concern would be the Hz difference, but that's not a deal breaker. How did your re-wiring of the BM go?

I used a smaller 220 plug than the drier type plug. I thought the drier plug was wayyyy bigger than I wanted on that small wire coming out of the kettle.

The one I used is about the size of a std 110 v plug except the two bars on itre horizontal instead of vertical.

sort of like this

_ _

o

instead of this

l l

o

Your sparky freind will know what I mean. I suggest you get and ext cord made too unless you know exactly where you want it. The cord is only about 5' long.

dinnerstick

Well-Known Member

fafrd- just to add to what psehorne has said, the only way the malt will be compacted into a solid mass is if you waaaay overload the malt pipe (or maybe if you try a 100% rye mash). normally the pump won't compress the mash, just gently push it towards the top screen. as you suggested, the grain bed sets upside-down when the pump is running. you will start to circulate very clear wort, but the grain bed gets disrupted when you finish the mash, and it has to reset at the bottom of the malt pipe for 'lautering' and sparging. of course to get perfectly clear wort you would then want to recirculate all of the wort through the new grain bed, but that's not really possible without an external pump, and the turbidity of the wort in practice is pretty low, so it's really not necessary. i make a little whirlpool after cooling, let is sit for 30 minutes or so, and run off very clear wort. you asked if anyone has stopped the pump and opened the malt pipe during the mash; this is pretty common practice, and highly recommended if your malt pipe is on the full side. it seems to help circulation, prevent channeling, or something, and get you much better efficiency. with low gravity beers (<1.055ish?) the flow through the mash is much better and i don't think stirring is as important.

fafrd- just to add to what psehorne has said, the only way the malt will be compacted into a solid mass is if you waaaay overload the malt pipe (or maybe if you try a 100% rye mash). normally the pump won't compress the mash, just gently push it towards the top screen. as you suggested, the grain bed sets upside-down when the pump is running. you will start to circulate very clear wort, but the grain bed gets disrupted when you finish the mash, and it has to reset at the bottom of the malt pipe for 'lautering' and sparging. of course to get perfectly clear wort you would then want to recirculate all of the wort through the new grain bed, but that's not really possible without an external pump, and the turbidity of the wort in practice is pretty low, so it's really not necessary. i make a little whirlpool after cooling, let is sit for 30 minutes or so, and run off very clear wort. you asked if anyone has stopped the pump and opened the malt pipe during the mash; this is pretty common practice, and highly recommended if your malt pipe is on the full side. it seems to help circulation, prevent channeling, or something, and get you much better efficiency. with low gravity beers (<1.055ish?) the flow through the mash is much better and i don't think stirring is as important.

Thanks dinnerstick (and psehorn) - so it sounds like the pump is powerful to force some or all of the grain bed up towards the false top but when the pump stops pumping, the grain falls back down to the false bottom - does that sound about right? If/when you stop the pump and remove the false top to stir the grain bed, has the grain bed pretty much all fallen back down by then (so you never get to actually see the raised grain bed)?

Also, it sounds like the grain bed is staying loose through the mash, so the force of the pump is enough to counteract gravity and force the grains upward, but not strong enough to cause any compaction - does that sound correct?

-fafrd

dinnerstick

Well-Known Member

Thanks dinnerstick (and psehorn) - so it sounds like the pump is powerful to force some or all of the grain bed up towards the false top but when the pump stops pumping, the grain falls back down to the false bottom - does that sound about right? If/when you stop the pump and remove the false top to stir the grain bed, has the grain bed pretty much all fallen back down by then (so you never get to actually see the raised grain bed)?

Also, it sounds like the grain bed is staying loose through the mash, so the force of the pump is enough to counteract gravity and force the grains upward, but not strong enough to cause any compaction - does that sound correct?

-fafrd

yep that's about the long and short of it, as far as i can tell. how loose the mash stays depends of course on the crush and composition of the mash as well as how full the pipe is. so it is possible that you open the top and see a somewhat compacted grain surface, but often in my experience this means over-filled mash pipe = poor circulation = poor efficiency. you should be able to get a mash paddle (well, wooden spoon) through it and to the bottom of the pipe pretty easily. when you get the pipe just to its limit, for me that usually means making around a 1.074 og wort, there's no room for the grain to settle back down when the pump is off, and you will see the grain pressed (lightly) against the top screen when you open it

Ragtop232

Well-Known Member

And here's where I believe the Braumeister gets it's great efficiency. The pump rest, in my opinion, is for the grain bed agitation. This is why I don't put any type of seal around the metal top and bottom plates to the malt pipe as this would hinder them from freely moving when the system has a pump rest. Also another reason to not overfill the malt pipe. In my opinion, if you want to do a big beer, up the grain bill and split it in half and mash twice, but don't stuff your malt pipe full. I think the pump rest is equivalent to stirring as the top plate retracts and the grain settles to the bottom only to be agitated again when the pump starts.

Jim

Jim

Flyhard

Member

- Joined

- Jul 19, 2012

- Messages

- 5

- Reaction score

- 0

I am thinking about a setup to use the pump of the braumeister for a hot whirlpool. Basic idea is taking some copper tubing and a rubber plug and fabricate a tube that fits into the outlet from the pump (with the rubber plug as a seal) and the other end comes closed out of the wort as a handle. Somewhere in the tube I'd mount a T-fitting and a piece of copper tubing as the whirlpool outlet.

Anyone got some experience with that?

Anyone got some experience with that?

Alchemy

Well-Known Member

I am thinking about a setup to use the pump of the braumeister for a hot whirlpool. Basic idea is taking some copper tubing and a rubber plug and fabricate a tube that fits into the outlet from the pump (with the rubber plug as a seal) and the other end comes closed out of the wort as a handle. Somewhere in the tube I'd mount a T-fitting and a piece of copper tubing as the whirlpool outlet.

Anyone got some experience with that?

Sounds like a good idea, just be sure that handle is truly sealed or you have your very own fountain of wort

yep that's about the long and short of it, as far as i can tell. how loose the mash stays depends of course on the crush and composition of the mash as well as how full the pipe is. so it is possible that you open the top and see a somewhat compacted grain surface, but often in my experience this means over-filled mash pipe = poor circulation = poor efficiency. you should be able to get a mash paddle (well, wooden spoon) through it and to the bottom of the pipe pretty easily. when you get the pipe just to its limit, for me that usually means making around a 1.074 og wort, there's no room for the grain to settle back down when the pump is off, and you will see the grain pressed (lightly) against the top screen when you open it

Thanks dinnerstick - I think I have the answers I was looking for. From what several of you Braumeister owners have seen, the pump is powerful enough to counteract the force of gravity and raise the grain bed, but not powerful enough to compress it in any way (so the grain bed falls back down due to gravity when the pump stops pumping). And as long as the grain pipe was not too-full, there will not be any significant compression against the false top.

Thanks again,

-fafrd

goodgodilovebeer

Well-Known Member

My 20L showed up today! :rockin:

Minimal surface damage on the inside of the kettle from the malt pipe rattling around in transit, no biggie. Now, just need to work on the electric portion of it all. Did I see somewhere back in the thread, that someone had found a replacement cord that plugs directly into the BM with a North American 220v plug? No cutting/splicing required? All I can recall is that it was black

BTW, thanks to everyone for documenting your experiences with this piece of equipment. It's amazing to see such an international group of people sharing their combined knowledge! The epic detail in Yambor44's YouTube videos is what made me decide to end a 15G 3-vessel system build, opting for the Braumeister.

Again,

Cheers!

Minimal surface damage on the inside of the kettle from the malt pipe rattling around in transit, no biggie. Now, just need to work on the electric portion of it all. Did I see somewhere back in the thread, that someone had found a replacement cord that plugs directly into the BM with a North American 220v plug? No cutting/splicing required? All I can recall is that it was black

BTW, thanks to everyone for documenting your experiences with this piece of equipment. It's amazing to see such an international group of people sharing their combined knowledge! The epic detail in Yambor44's YouTube videos is what made me decide to end a 15G 3-vessel system build, opting for the Braumeister.

Again,

Cheers!

psehorne

Well-Known Member

Did I see somewhere back in the thread, that someone had found a replacement cord that plugs directly into the BM with a North American 220v plug? No cutting/splicing required?

For the 20L

5ft NEMA L6-20P to C13, 14/3 SJT (15A 250V)

AC Power Cord L6-20 Plug to IEC 60320 C13 Connector 15 Feet 15a/250v 14/3

Last edited by a moderator:

psehorne

Well-Known Member

Last edited by a moderator:

goodgodilovebeer

Well-Known Member

Thanks psehorne! Did you end up going this route?

psehorne

Well-Known Member

Thanks psehorne! Did you end up going this route?

Yes. I bought one of each length.

So close to pulling the trigger on this... even got a tentative OK from the wife for the 20L.

Some questions:

1. Is that cord all I need to get going? No assembly required? I just plug it into the 220v stove socket, right?

2. I don't want to spend all this money only to still need to mess around sparging. What kind of efficiency can I expect without sparging?

3. When doing a no-Sparge, roughly how much grain can the 20l reliably hold without issue?

4. Are morebeer and morebeer4u the only US distributors?

Thanks!

Some questions:

1. Is that cord all I need to get going? No assembly required? I just plug it into the 220v stove socket, right?

2. I don't want to spend all this money only to still need to mess around sparging. What kind of efficiency can I expect without sparging?

3. When doing a no-Sparge, roughly how much grain can the 20l reliably hold without issue?

4. Are morebeer and morebeer4u the only US distributors?

Thanks!

Alchemy

Well-Known Member

So close to pulling the trigger on this... even got a tentative OK from the wife for the 20L.

Some questions:

1. Is that cord all I need to get going? No assembly required? I just plug it into the 220v stove socket, right?

2. I don't want to spend all this money only to still need to mess around sparging. What kind of efficiency can I expect without sparging?

3. When doing a no-Sparge, roughly how much grain can the 20l reliably hold without issue?

4. Are morebeer and morebeer4u the only US distributors?

Thanks!

1. Yup! I made my own cord since the plug I had in my brewery is a 3 prong 240 but i plan on ordering one of those for when I brew outside in order to use my 220 dryer outlet. The c13 to 220 that you linked should work for you.

2. I have gotten about 75 to 80 on average

3. Around 13lbs is the max as far as I am concerned , others might have had a different experience but for me at 13lbs the mash is very tight packed and channeling becomes an issue with any more grain.

4. The only ones I have seen yes.

Alchemy

Well-Known Member

Edit: duplicate

psehorne

Well-Known Member

1. Is that cord all I need to get going? No assembly required? I just plug it into the 220v stove socket, right?

No. Sorry if I misled you. The male plug on the cord I linked you to is NOT a mate to an electric clothes dryer outlet. It requires a matching L20-6R receptacle available at most local hardware stores.

No. Sorry if I misled you. The male plug on the cord I linked you to is NOT a mate to an electric clothes dryer outlet. It requires a matching L20-6R receptacle available at most local hardware stores.

OK. So am I right in thinking I need the cord you linked to AND the l20-6R receptacle? I'm having trouble picturing this is my head.

Am I right in guessing the receptacle plugs into my stove outlet, then the cable you linked to plugs into the receptacle? I then just connect the Braumeister to the cable: http://www.stayonline.com/detail.aspx?id=8951

psehorne

Well-Known Member

OK. So am I right in thinking I need the cord you linked to AND the l20-6R receptacle? I'm having trouble picturing this is my head.

Am I right in guessing the receptacle plugs into my stove outlet, then the cable you linked to plugs into the receptacle? I then just connect the Braumeister to the cable: http://www.stayonline.com/detail.aspx?id=8951

No. Your clothes dryer plug would need to be replaced with the L20-6R... probably not something that you want to do. I installed a separate L20-6R receptacle at my brew station, not in my utility room where the clothes dryer resides.

I did not realize that you wanted to user your clothes dryer outlet. If you want to use your clothes dryer outlet then you need to make up a cord with the proper matching plug and a C13 plug on the other.

EDIT: Sorry, I had clothes dryer on my mind for some reason. I should have stated that the L20-6 is not the same as the receptacle for your stove (nor your clothes dryer).

I think I get it now, thanks! So basically there's no simple plugin adapter for US stove/drier 220v plug to German 220v plug then?

psehorne

Well-Known Member

I think I get it now, thanks! So basically there's no simple plugin adapter for US stove/drier 220v plug to German 220v plug then?

Probably not. The stove/dryer connections are probably 50 to 60 amp connections. It is highly unlikely that anyone makes a 15 amp C13 to connect to a 50 amp circuit.

Similar threads

- Replies

- 11

- Views

- 2K