LTownLiquorPig

Well-Known Member

Still an extract kit brewer (Cooper's, adding my own hop additions) but starting to seriously think I'd like to move into AG. Gotta say after lots of digging on here I'm not enamoured with the idea of propane outdoors. I don't have much time to brew in the summer, and winters here would be less than appealing to brew in as well. So electric seems to be the ticket. I can brew indoors, year round (evenings in the summer with no flies!)

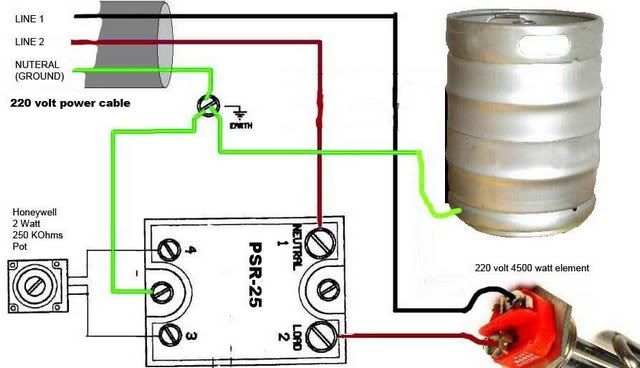

My plan is to create brew space in the basement, and start off with an e-kettle with some type of temp control, then mash in a cooler, then boil in the same kettle. What I have going for me is the area swmbo will allow me is beside the main panel, so adding a 240V outlet would be fairly cheap and easy. Same goes for a range hood.

Here's my question: how can I build a kettle that will give me flexibilty to do 10 gallon batches, with a fairly simple temp control to get to mash temps, then boil as well, on the lower end of the budget range. I have a buddy who's a welder and a buddy who's an electrician, but I'd rather not approach them until I solidly understand what I'm asking of them. I've been digging through posts for a couple weeks and can't find what I'm looking for.

For clarity, I'm not interested (at this point) in anything more than the single kettle and cooler set up. No pumps, just kettle.

Thanks for any help folks!

My plan is to create brew space in the basement, and start off with an e-kettle with some type of temp control, then mash in a cooler, then boil in the same kettle. What I have going for me is the area swmbo will allow me is beside the main panel, so adding a 240V outlet would be fairly cheap and easy. Same goes for a range hood.

Here's my question: how can I build a kettle that will give me flexibilty to do 10 gallon batches, with a fairly simple temp control to get to mash temps, then boil as well, on the lower end of the budget range. I have a buddy who's a welder and a buddy who's an electrician, but I'd rather not approach them until I solidly understand what I'm asking of them. I've been digging through posts for a couple weeks and can't find what I'm looking for.

For clarity, I'm not interested (at this point) in anything more than the single kettle and cooler set up. No pumps, just kettle.

Thanks for any help folks!