What a killer idea! I like those larger milk crates. Thanks for the link!!

Cheers

Jay

Cheers

Jay

Well, I'm decidedly taking the hard route by using fittings and fully sweated copper risers. I'm about 8+ hours of labor into this thing. My unit is not even close to being the product of a "lazy homebrewer." Haha. But, I'm getting close to wrapping it up...just need to finish gluing up the CPVC.

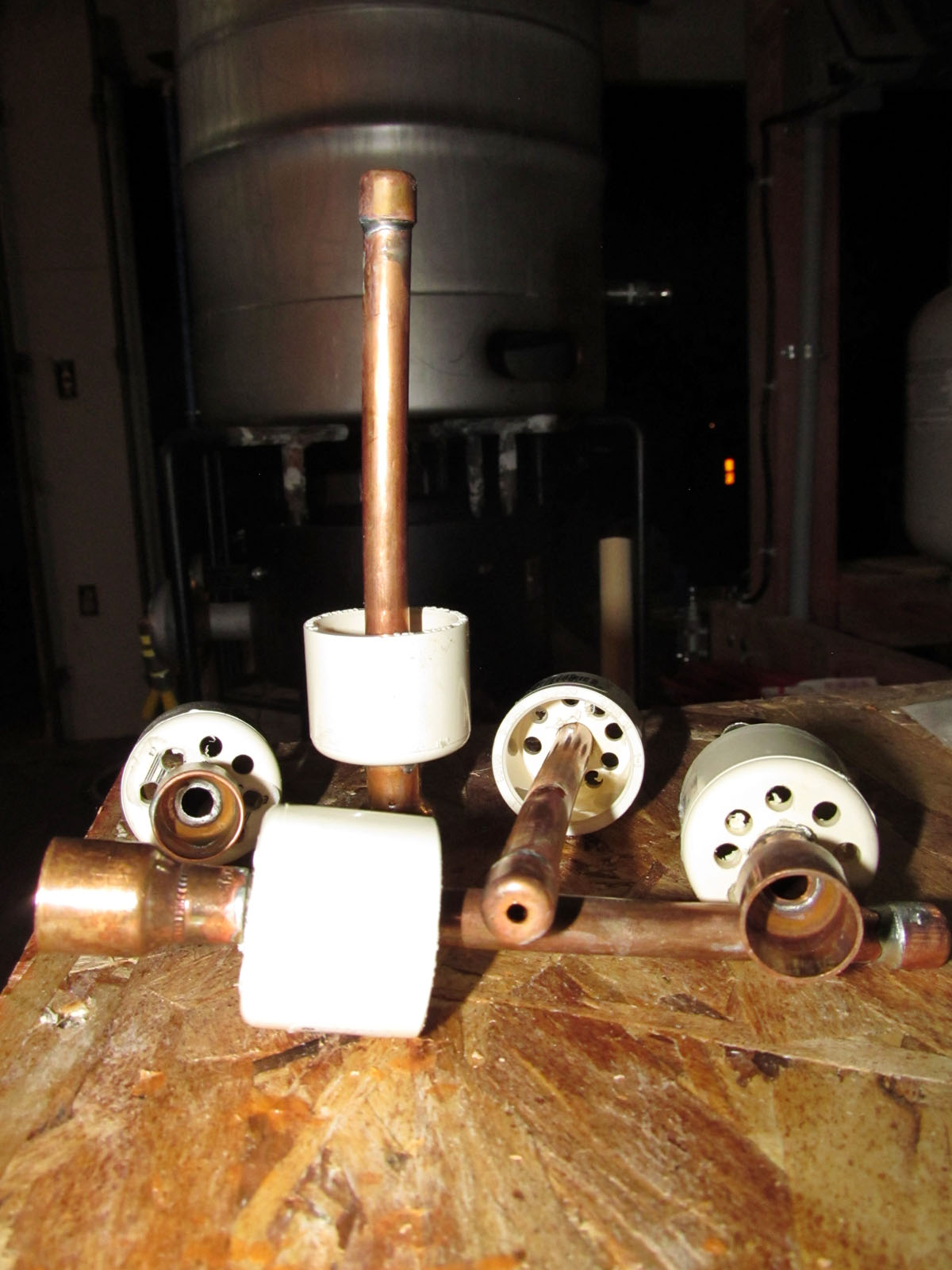

Thought I'd provide you an update, though. I finished the copper sweats tonight for all 24 risers, including my drilled caps. I'm happy to report that, with full restriction across all risers and using 1/8" holes in the caps, I'm getting upwards of 5-6' of water height from each riser. The stream has some pretty decent power, too, especially at 4-5" above where the base of the bottle will be . I'm going to hold off on drilling out the caps to 3/16" until I can get a better test.

My initial testing was somewhat precarious since I haven't glued it together yet. There's some serious water pressure going on & it's blowing the fittings! Unfortunately, it was too precarious to get any pics of it in operation before it fell completely apart on me. But so far, my short testing showed it's going to perform.

I'm not 100% settled on my bottle mounting mechanism, a 1" cap. I discovered when using the 1/2" to 1/4" reducer couplings, it will virtually plug up the entire mouth of the bottle and this will fully stop the spout from working at all. So, if you intend to use fittings, you have to figure out a way to get the bottle off the riser to allow it to properly drain. As you'll see, I drilled out a pattern in the 1" caps to address this issue. They're mostly sturdy, but I think I may seek another method. I'm still tossing around a few ideas.

I'll try to wrap things up tomorrow night, at least so I can show you what my design looks like overall, but for now, I'll leave you with this:

Think if you moved the rinsers closer together you could make an automatic nettipot?

Wow, that's stunningly cool! Are you getting sufficient drainage from the caps?

Holy guacamole! How is that happening? Is that the bigger pump and the smaller exit diameter?

nicely done, imma build one....may make a few more mods. I'd love to figure out how to add some filtration w/o reducing the flow rate. I'd also like to mod the tube tips to work more like sprinkler heads. nice project and what's better...no rush. me thinks it will be a six-banger and I will clean them as I use them.....don't want to store up 24 "dirty" bottles.....

and many thanks to you and Malfet for sharing.

I just made one based on your design. I used rubber grommets to connect from the cpvc to the copper. I also went with the pump recommended but the 1/3 hp one. Got it all together and works great! My one question is do you think there will be any leaching of chemicals from the rubber grommets? I do not think they are food grade however they came with limited information. The grommets have a "tire" smell out of the bag.

Great idea about the grommets! I have no idea about the food safety. If you could find pure silicon grommets, that would certainly be good, but we'd have to know more about the kind of rubber to really guess about food safety.

Funny, I had this same idea not too long ago because I have many cases of wine bottles that I need to wash. I however, want to wash both inside and out. I also want the ability to toss labeled bottles in and have the heat/water/cleaning solution de-label the bottles. I'm working on mine now and I'll post my results soon. Nice job!

evancold said:well I asked the seller I bought the grommets from and he said he would not use them for this application. Now the search continues to find the proper grommets. Dang! was hoping to use this thing today for the first time with bottles.

I'm really intrigued by the grommet idea.

I love all the various directions people have run, but I'm personally still very attached to the 30-bottles-in-a-milkcrate design. Being able to go seamlessly from storage to washing is key to my needs.

But, the one part I'm still unhappy with is the JB Weld. It works fine enough and I'm comfortable that its food safe, but it's just more futzy, fragile, and time consuming than I'd like. Some simple grommets would be incredibly convenient.

Please keep us posted if you find anything!

This is the closest I can find, says they are silicone. Do you think these will work?

http://www.drillspot.com/products/5...military_specification_rubber_grommet#reviews

The measurements look good, but man-oh-man, that ain't cheap. If we could figure out the type of rubber in the other stuff, I'd feel more confident.

Come on... help the "unskilled" brewers like me... post a parts-list!.

Did you check the section in the OP labeled Parts?

I just figured it out... I went from the home page and could not get to the parts list.

Went in DIY and there it was....

Edited my post so I did not look like a complete (xxxxx)!

Huh, weird. Glad it worked in the end!

This is the closest I can find, says they are silicone. Do you think these will work?

http://www.drillspot.com/products/5...military_specification_rubber_grommet#reviews

I think those will be just fine. At a melting point between 400-450 degrees, you'd be pumping aerosolized gas before you had any problems. I couldn't find any particular food safety info on the standards, but silicone is usually safe.

Enter your email address to join: