ExHempKnight

Well-Known Member

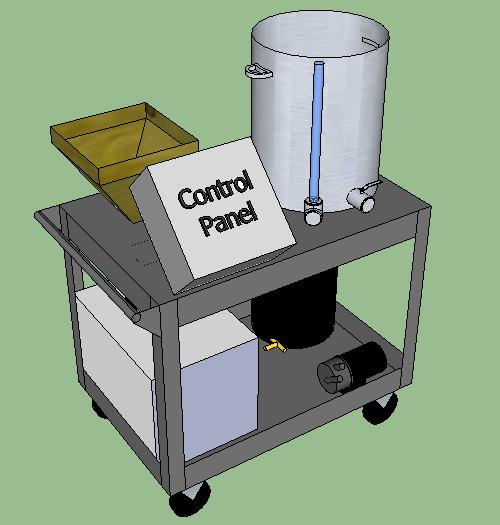

I guess I'm close enough to building this thing, that I can share. It's an amalgamation of several ideas I've gleaned from people, and combined into a do-it-all brewing rig.

I'll be building it on a cart for portability. It will consist of a motorized grain mill, a single-vessel BIABasket system (a la ScubaSteve), a Bobby_M style CFC, on board water filter, an on-board ventilation system, and a 20-gallon tank with a submersible pump (which will collect the CFC cooling water for later cleaning use).

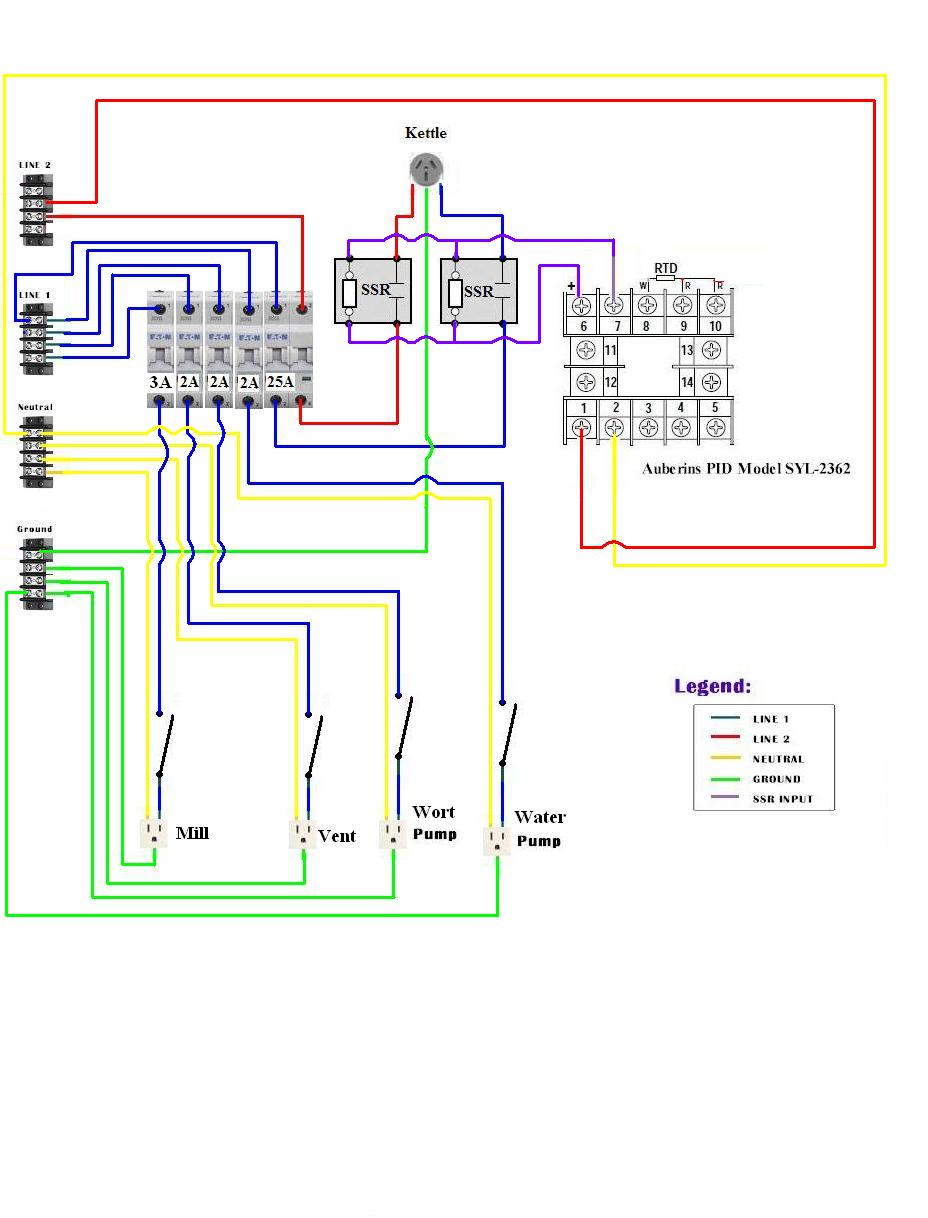

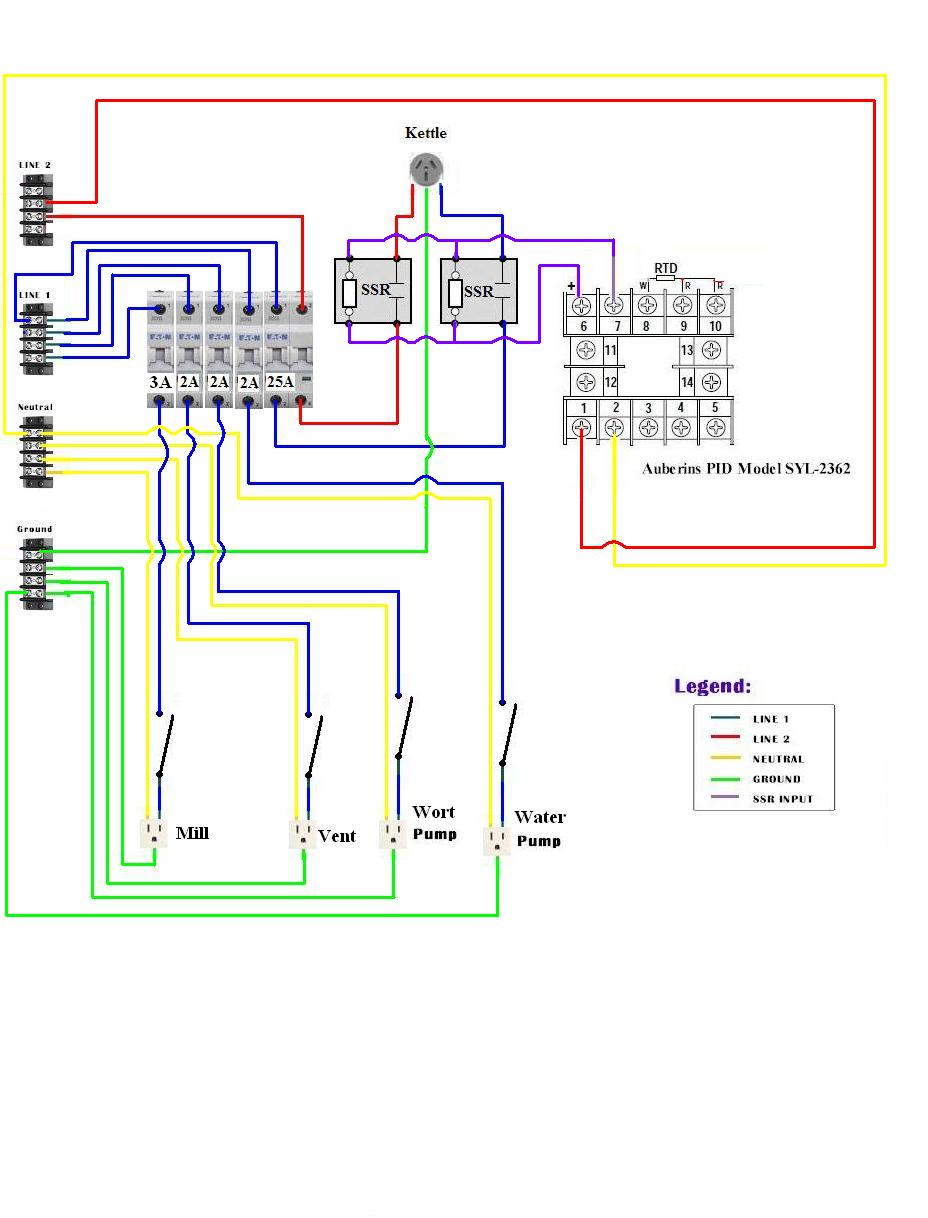

First, the Control Panel schematic (thanks again to P-J for being cool with me stealing and modifying this for my own purposes):

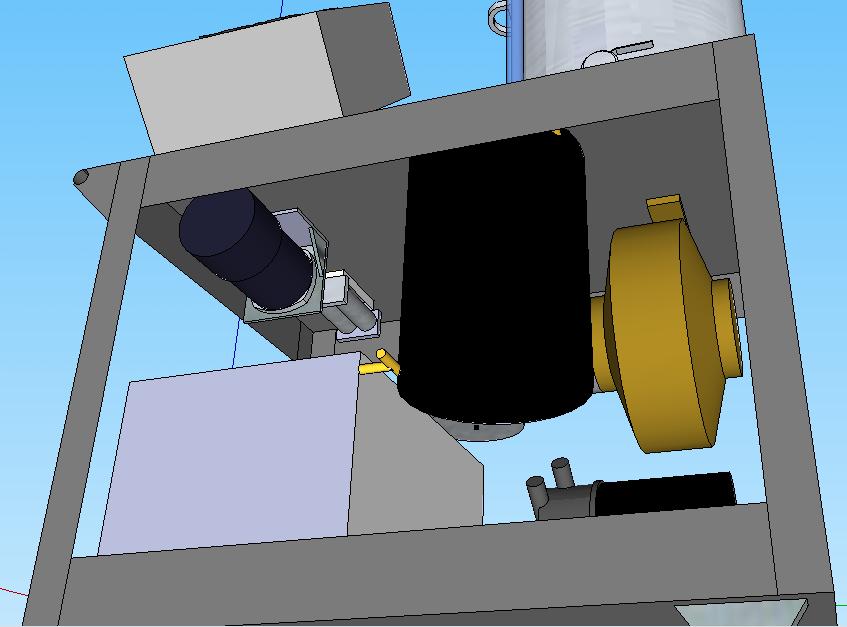

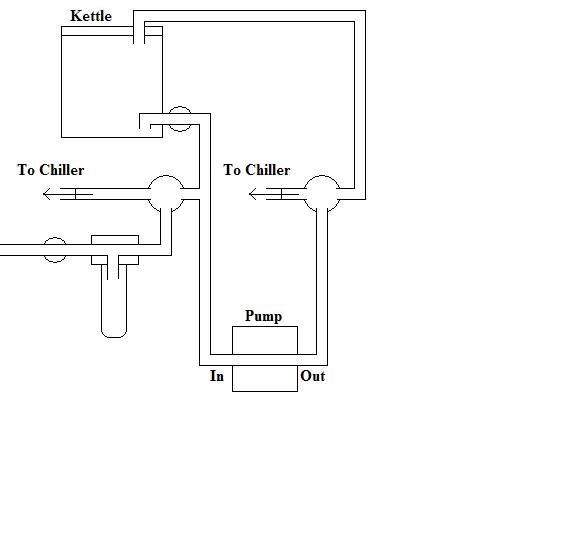

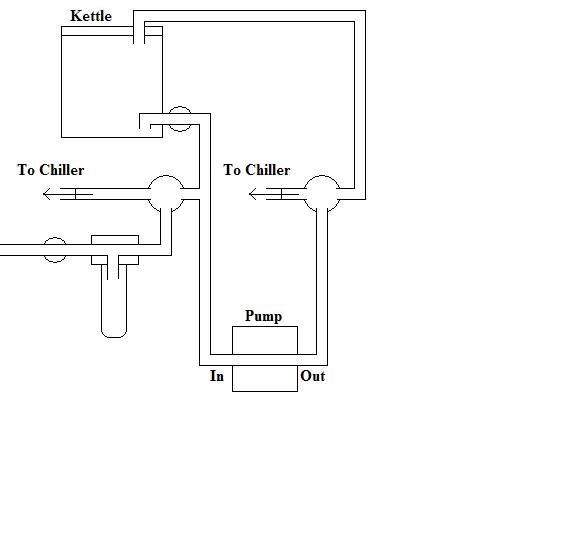

Next, the plumbing:

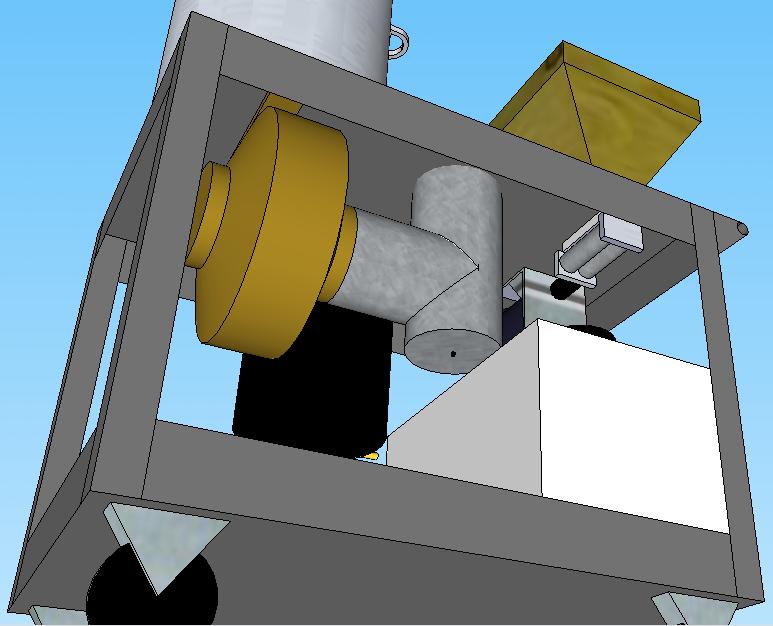

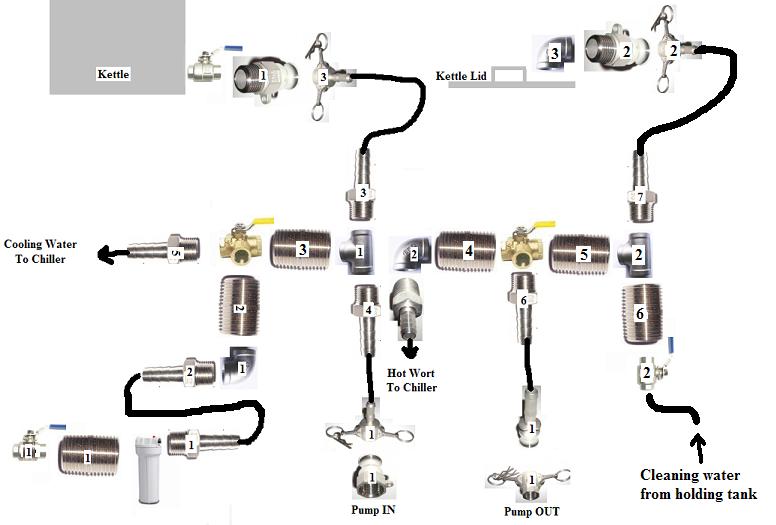

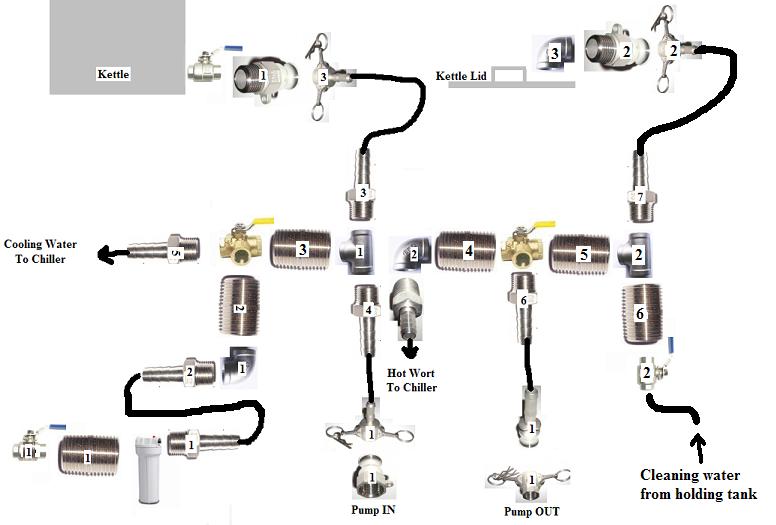

The plumbing again, this time as a parts diagram:

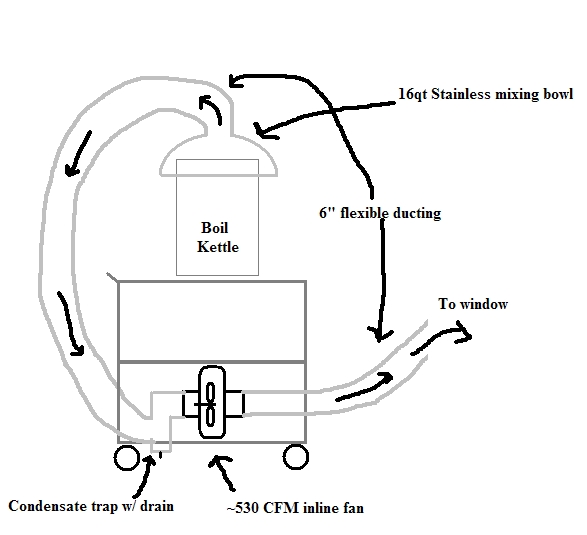

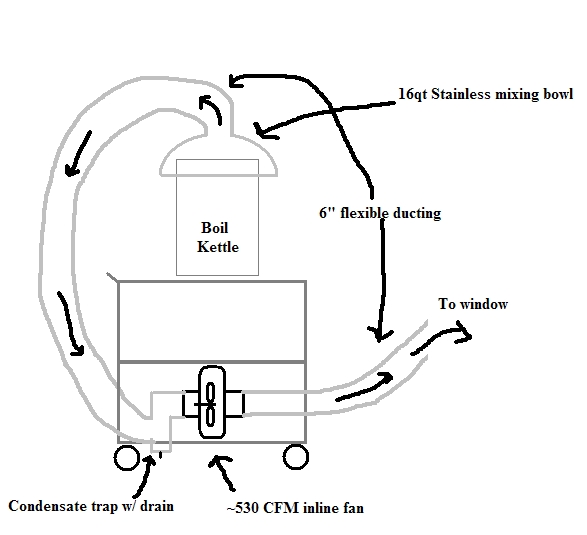

And finally, a crude concept drawing of the vent system:

Constructive criticism is most welcome. Thanks!

I'll be building it on a cart for portability. It will consist of a motorized grain mill, a single-vessel BIABasket system (a la ScubaSteve), a Bobby_M style CFC, on board water filter, an on-board ventilation system, and a 20-gallon tank with a submersible pump (which will collect the CFC cooling water for later cleaning use).

First, the Control Panel schematic (thanks again to P-J for being cool with me stealing and modifying this for my own purposes):

Next, the plumbing:

The plumbing again, this time as a parts diagram:

And finally, a crude concept drawing of the vent system:

Constructive criticism is most welcome. Thanks!