LeBreton

Well-Known Member

Been doing a lot of research recently on the history of cider, both foreign and domestic. Spending time combing through the Cornell University library catalogs and rare book depository, sifting through a lot of unhelpful text and occasionally uncovering some hidden gems.

Thought I'd share a few with you guys . . .

- In 1813, a popular war tune about how American Perry was better than British cider as often sung in US bars. A reference to a naval victory by Commodore Perry over British naval forces on lake Erie. Also a nod to the fact the the Brits halted all imports of US apples following the revolution. That is until 1838 when US politician Andrew Stevenson brought a bushel of Newtown Pippins as a gift for Queen Victoria and the ban was lifted.

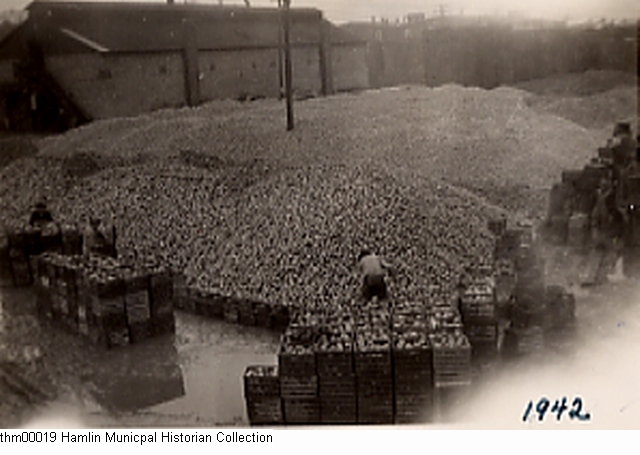

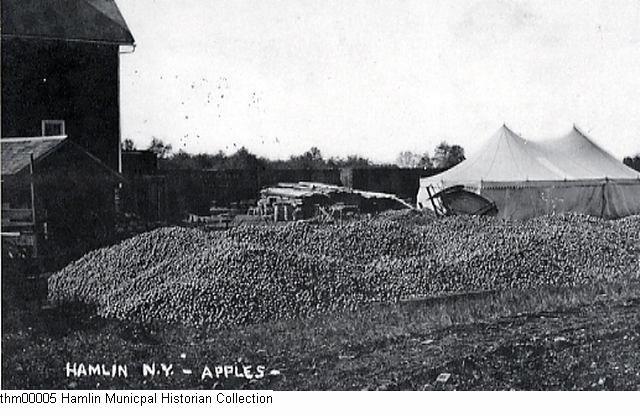

- From the 1840s until prohibition, one of the larger cider producers was the Genesee Fruit Company, now known as Mott's.

- Keeving cider seems to have been a common occurrence through the mid 1800's in this country, but by the turn of the century seems to be relatively unknown here while remaining typical in Europe. I'm thinking that innovation in grinding & pressing technologies may be responsible, which resulted in more efficient workflow and less time between grinding and pressing and thus less pectin in the juice.

- Think hopped cider is a new development? I sure did, until I came across a recipe from 1867.

More to come if people find these as interesting as I do.

Thought I'd share a few with you guys . . .

- In 1813, a popular war tune about how American Perry was better than British cider as often sung in US bars. A reference to a naval victory by Commodore Perry over British naval forces on lake Erie. Also a nod to the fact the the Brits halted all imports of US apples following the revolution. That is until 1838 when US politician Andrew Stevenson brought a bushel of Newtown Pippins as a gift for Queen Victoria and the ban was lifted.

- From the 1840s until prohibition, one of the larger cider producers was the Genesee Fruit Company, now known as Mott's.

- Keeving cider seems to have been a common occurrence through the mid 1800's in this country, but by the turn of the century seems to be relatively unknown here while remaining typical in Europe. I'm thinking that innovation in grinding & pressing technologies may be responsible, which resulted in more efficient workflow and less time between grinding and pressing and thus less pectin in the juice.

- Think hopped cider is a new development? I sure did, until I came across a recipe from 1867.

More to come if people find these as interesting as I do.