Huaco

Well-Known Member

NOt sure I follow.. I must be missing something simple.

Sorry... I was thinking of something else... See above. I edited my post.

NOt sure I follow.. I must be missing something simple.

Thanks!!

I will find out tonight. I am brewing a batch that has a grist of 12.8 lbs. My overall deadspace was about 1/2 gallon.

Tonight is a Rye based beer so I hope not to have a stuck sparge. My buddy bought the ingredients, so I hope my fabrication doesn't screw up his brew.

Sidenote, I had someone tell me that using aluminum was a bad idea based on ionization. Now as a chemist, I don't think that really applies to the false bottom. Also people use aluminum boil kettles all the time.

Next time around I will be getting a stainless steel plate and have a buddy with a drill press makes the holes, but until then...I hope this works!!!

Well, the rye beer was a total flop. I ended up with a horruble stuck sparge that was there no recovering from. I ended up using a kitchen collander and scooping ut the spend grains. It was a disaster. At first I thought it was the rye, but I am thinking something went wrong with the false bottom. There was a large grain stuck in the silicone tubing. So, grain got through. Oh well live and learn. Its not enough for me to give up on my cheap creation yet.

We did drain slowly, but I think you may be right abou the floating bottom. Gonna have to get a stainless steel one and have a buddy with a drill press drill it for me.

My brewing buddy thinks maybe the 1/8 inch holes are too big? Any thoughts on that?

We did drain slowly, but I think you may be right abou the floating bottom. Gonna have to get a stainless steel one and have a buddy with a drill press drill it for me.

My brewing buddy thinks maybe the 1/8 inch holes are too big? Any thoughts on that?

Be careful. I used aluminum and its lighter than SS, so it ended up floating when i added the water. Hence I ended up with stuck sparge due to grains getting under it. Although, this is only one of my many theories as to what screwed up that brew day. It was a BAD brew session.

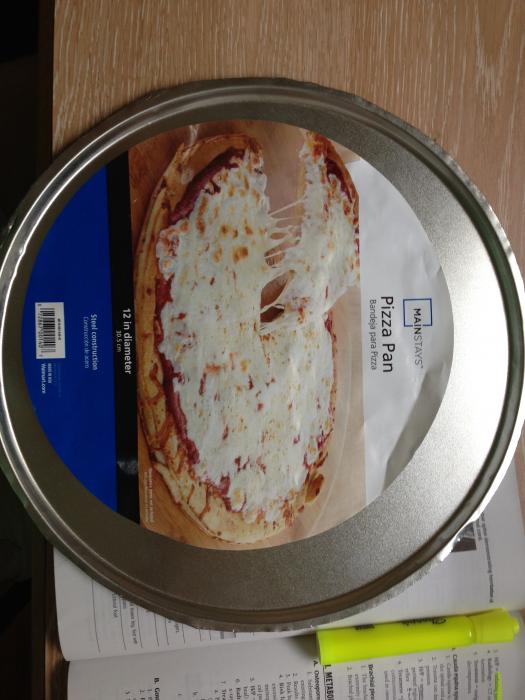

I loved this idea and I went with it. I found a pizza pan that says "steel" construction from Walmart. Any idea if this would be safe in a mash tun? I trimmed it down to size and it fits perfectly into the 10 gal rubbermaid. Here's a picture.

I loved this idea and I went with it. I found a pizza pan that says "steel" construction from Walmart. Any idea if this would be safe in a mash tun? I trimmed it down to size and it fits perfectly into the 10 gal rubbermaid. Here's a picture.

Dude this is great. I added the SS 12" to my wishlist on amazon yesterday and it was $14 bucks. Looked at it today and it dropped to $8.56 with free second day shipping cuz of my Prime membership. I had been debating getting the FB from Jaybird for my 10G rubbermaid but i think this just saved me a ton of money.

Also for the barb issue, try a dremel sanding tool, thats what im gonna use. It worked great for the sharp edges on my keggle cuts.

One question though... how does it hold up with large grain bills? Any issue with bending?

Awesome, well I'm gonna go for it because it was only $0.98 at Walmart. zzARzz how did you get the barbs off the bottom? I might just get pliers for the big ones and leave the little ones.

Instead of drilling I wonder if an awl could punch a hole that would work (providing it's thin enough stainless/aluminium). Use a piece of wood as a backer. Might go quicker...

Just finished up the holes earlier. Used my DeWalt drill and alternated two 1/8" bits with drill oil and after about an hour I got them all done. Gonna take the dremel to it tomorrow or Sunday when I get time and then head to Lowes to get the elbow and tubing. Can't wait to see how it turns out.

I loved this idea and I went with it. I found a pizza pan that says "steel" construction from Walmart. Any idea if this would be safe in a mash tun? I trimmed it down to size and it fits perfectly into the 10 gal rubbermaid. Here's a picture.

It's a pizza pan so it's food grade, give it a shot.

So glad I found this thread! I am for sure doing this. Going to pick up the following off of amazon:

http://www.amazon.com/Stainless-Steel-Pizza-Pan-Diameter/dp/B002UG7QVI/ref=sr_1_1?ie=UTF8&qid=1374276111&sr=8-1&keywords=stainless+steel+pizza+pan

Based on the reviews, I am loving the possibility of this being a great false bottom:

"...the lip is a good 1 1/2 inches and the graduation makes this a one use pan..."

...not for me it doesn't. Sounds awesome!

12 bucks for the SS Pizza Pan + another 5 bucks for other hardware to hook it all up = totally kick ass false bottom for under 20 bucks!

"Food grade" is not a good measure for this (ab)use. In the short run it may hold up, but since your mash is sour (pH of around 5.2) it will degrade (dissolve) the tin coating on the pan and then attack the steel. Aluminum won't fare any better.

Using a SS pan is the only way to keep it from becoming part of your beer.

The burrs can be removed by spinning a slightly larger drill bit in the burr-side of the holes. A very, very slow running drill can help if you don't want to do it by hand, just watch out it doesn't "catch" and make a bigger hole. Dremel tools are useful too.

Enter your email address to join: