abraxas

Well-Known Member

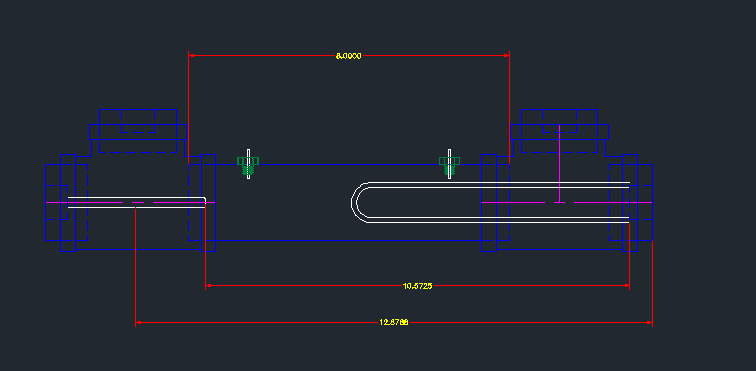

In putting together my RIMS system I have acquired a level sensor: http://ecatalog.gemssensors.com/ecatalog/warrick-controls/en/16HMJ1A0

I'd like to use it to shut off power to the heating element if it doesn't see continuity between two points in the RIMS tube. I've got it figured out from an electrical standpoint but I am not sure how to approach this from a physical standpoint.

I was thinking about drilling two holes in the rims tube and filling them in with JB WaterWeld with the two sensors centered in each hole so as to not make contact with the stainless steel tube. I'm a little bit leary about chemical leaching from the waterweld (I know its not much and shouldn't be a big deal) and I don't like the permanence of this idea in case one of the sensors becomes fouled.

I have also thought about drilling holes and threading them (it's sch40 pipe) to put some plastic plugs with the sensors imbedded. But I am not sure if I will run into problems with different materials and thermal expansion, etc.

Does anybody have a more practical suggestion? Maybe a combination of the two would be a best bet (tapped hole in pipe with Waterweld as a backup seal).

I'd like to use it to shut off power to the heating element if it doesn't see continuity between two points in the RIMS tube. I've got it figured out from an electrical standpoint but I am not sure how to approach this from a physical standpoint.

I was thinking about drilling two holes in the rims tube and filling them in with JB WaterWeld with the two sensors centered in each hole so as to not make contact with the stainless steel tube. I'm a little bit leary about chemical leaching from the waterweld (I know its not much and shouldn't be a big deal) and I don't like the permanence of this idea in case one of the sensors becomes fouled.

I have also thought about drilling holes and threading them (it's sch40 pipe) to put some plastic plugs with the sensors imbedded. But I am not sure if I will run into problems with different materials and thermal expansion, etc.

Does anybody have a more practical suggestion? Maybe a combination of the two would be a best bet (tapped hole in pipe with Waterweld as a backup seal).