You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New 10 Gallon Herms! Pics!

- Thread starter The Pol

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Kauai_Kahuna

Well-Known Member

The Pol - Thanks, that is something I'm going to have to take a hard look into.

The Pol

Well-Known Member

- Joined

- Feb 12, 2007

- Messages

- 11,390

- Reaction score

- 117

NO problem, if you need any help, have any questions, I am not a professional, but I have learned alot through $$$$$ trial and error $$$$$, and I would be glad to help in order to save you time, money, agony, tears...!

The Pol

Well-Known Member

- Joined

- Feb 12, 2007

- Messages

- 11,390

- Reaction score

- 117

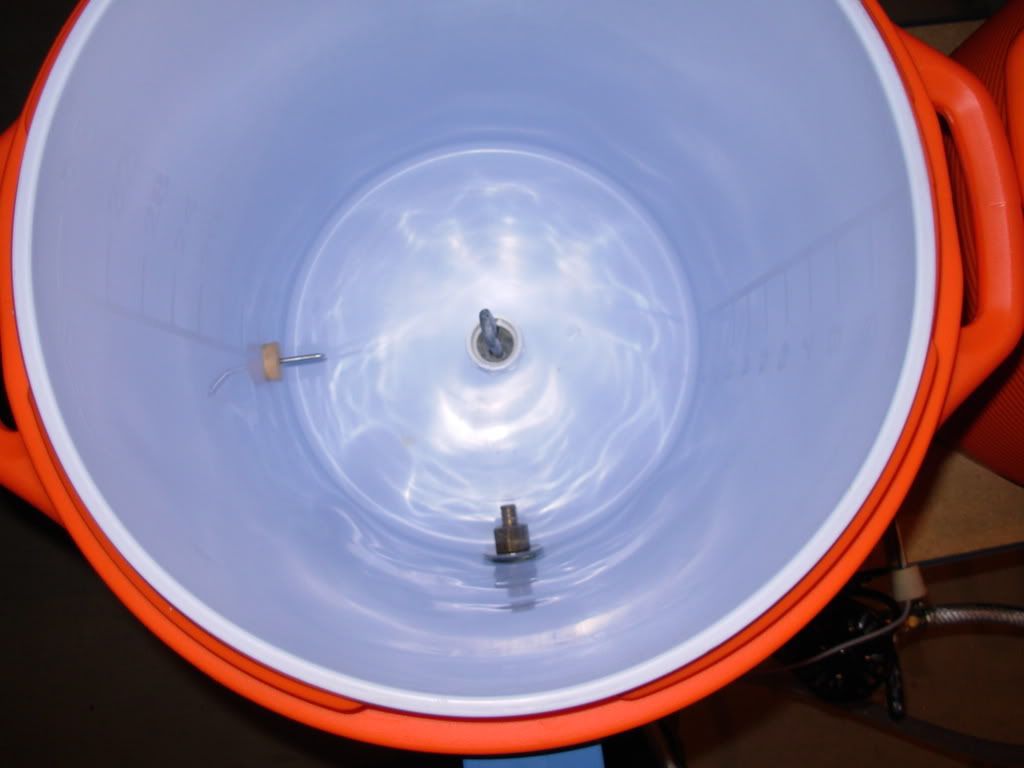

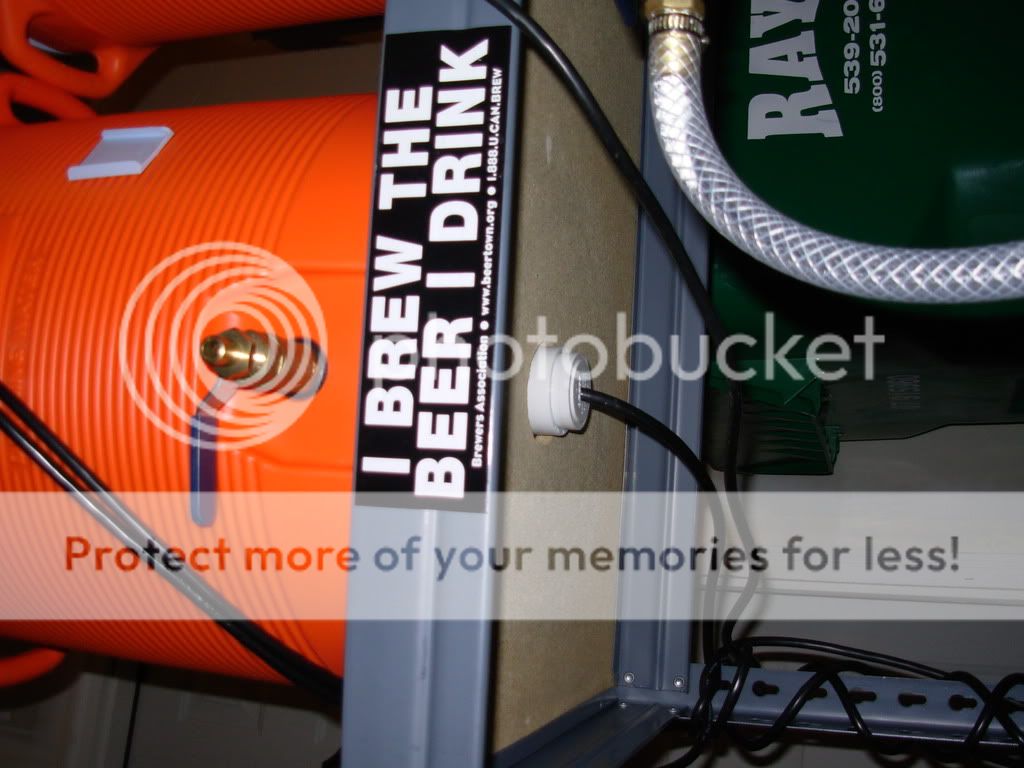

Here are my final pics! I have the water stirrer installed, perfect fit from McMaster Carr. Just kicked a keg today, so it is a good thing that I have this thing operational so that I can brew again! ENJOY!

THE BEAST

HLT secondary thermometer

MLT Mash thermometer

Sealed heating element compartment

THE BEAST

HLT secondary thermometer

MLT Mash thermometer

Sealed heating element compartment

Is it all wired into the laptop or is that just for recipe info?

DaleJ

Well-Known Member

Pol,

Can you provide a materials list at some point?

In particular, I'm interested in the coolant tubing you're using for the return flow in the mash tun.

Can you provide a materials list at some point?

In particular, I'm interested in the coolant tubing you're using for the return flow in the mash tun.

The Pol

Well-Known Member

- Joined

- Feb 12, 2007

- Messages

- 11,390

- Reaction score

- 117

Yeah, I am actually in the middle of my inaugural brew on this thing, so far, so great... no leaks, temps have only fluctuated by .5F in the mash... ramping up to mashout now! Id be happy to get a materials list up, most of this was trial and alot of error on my part, alot of headaches are paying off today! Pics to come later!

The Pol

Well-Known Member

- Joined

- Feb 12, 2007

- Messages

- 11,390

- Reaction score

- 117

The brew session turned out great, not a drop of lost wort or water... I am planning a Duvel Clone and I will be using this setup to perform a ramp mash that will continually heat from 99F to 168F over a 2 hour period, per the clone recipe. I will have a couple sets of batteries on hand to do this, as I know how much homebrewers like pics!

I can heat my HERMS water, without the recirculation process, at 2F per minute, while recirculating the mash, it is closer to .5F per minute as it heats the mash. This should allow for a nice gradual and even heating of the mash for the Duvel.

I can heat my HERMS water, without the recirculation process, at 2F per minute, while recirculating the mash, it is closer to .5F per minute as it heats the mash. This should allow for a nice gradual and even heating of the mash for the Duvel.

RockfordWhite

Well-Known Member

- Joined

- Dec 3, 2007

- Messages

- 473

- Reaction score

- 11

Did you add your thermometer to the mash tun the same way with a stopper? Do you ever notice any leaks?

The Pol

Well-Known Member

- Joined

- Feb 12, 2007

- Messages

- 11,390

- Reaction score

- 117

The mash tun thermometer is the same as the HLT secondary therm. It is a solid stopper with a probe thermometer shoved through it. There is not a single leak in my entire system. I took great care in using some good o-rings and using teflon tape on all the fittings, the probe thermometers are almost impossible to remove from the stoppers, therefore no leaks.

A couple questions for you...

You seem to be controlling your mash temp by measuring the HLT temp with your controller. Is that right? Do you find that setting that temp to your desired mash temp actually gives you the ultimate mash temp you want or do you need to go +1 or so?

Using a cooler based mashtun is usually enough to hold temp so what is your motivation for HERMS? It seems that running the pump, stirrer and element during the entire mash is fixing a problem that doesn't exist. Is suppose if you triggered the pump off a mash-based controller and probe, it would only kick on when necessary (probably once during the entire mash).

When you're done mashing and ready to start sparging, do you ramp up your HLT temp via the controller to 168 and continue the HERMS recirc to mash out? I would imagine this is where a slightly stronger element would help because it probably doesn't do 1F rise per minute when heating the sparge water and mash itself from 150-168.

What is that flex MLT return doohicky and where did you get it? I've seen that kind of thing on machining tools for coolant delivery but don't know what to search for to find it.

You seem to be controlling your mash temp by measuring the HLT temp with your controller. Is that right? Do you find that setting that temp to your desired mash temp actually gives you the ultimate mash temp you want or do you need to go +1 or so?

Using a cooler based mashtun is usually enough to hold temp so what is your motivation for HERMS? It seems that running the pump, stirrer and element during the entire mash is fixing a problem that doesn't exist. Is suppose if you triggered the pump off a mash-based controller and probe, it would only kick on when necessary (probably once during the entire mash).

When you're done mashing and ready to start sparging, do you ramp up your HLT temp via the controller to 168 and continue the HERMS recirc to mash out? I would imagine this is where a slightly stronger element would help because it probably doesn't do 1F rise per minute when heating the sparge water and mash itself from 150-168.

What is that flex MLT return doohicky and where did you get it? I've seen that kind of thing on machining tools for coolant delivery but don't know what to search for to find it.

The Pol

Well-Known Member

- Joined

- Feb 12, 2007

- Messages

- 11,390

- Reaction score

- 117

A couple questions for you...

You seem to be controlling your mash temp by measuring the HLT temp with your controller. Is that right? Do you find that setting that temp to your desired mash temp actually gives you the ultimate mash temp you want or do you need to go +1 or so?

Using a cooler based mashtun is usually enough to hold temp so what is your motivation for HERMS? It seems that running the pump, stirrer and element during the entire mash is fixing a problem that doesn't exist. Is suppose if you triggered the pump off a mash-based controller and probe, it would only kick on when necessary (probably once during the entire mash).

When you're done mashing and ready to start sparging, do you ramp up your HLT temp via the controller to 168 and continue the HERMS recirc to mash out? I would imagine this is where a slightly stronger element would help because it probably doesn't do 1F rise per minute when heating the sparge water and mash itself from 150-168.

What is that flex MLT return doohicky and where did you get it? I've seen that kind of thing on machining tools for coolant delivery but don't know what to search for to find it.

The differential between the HLT and the MLT temp on my first brew last week was 2-3F... that was it. There is a fair ammount of hose, the pump etc... 2-3F seemed to work really well over the course of the mash.

Using these coolers over the past several years I have lost from 3-5F over the course of an hour mash, along with hot and cold spots. This was not good enough for me. Also, if my strike water was a little off, there was no easy way of adjusting my mash temp. Also, there was really no mashout because the ammount of boiling water that I needed to add to my already cold mash was too large for the cooler in alot of cases. I also did not have clear wort. There was a problem as far as I was concerned with the straight cooler MLT. I see no real issue in recirculating the mash water during the entire mash, other than the $.05 that it costs me to do so. Adding another switch to control the March pump would just add more complexity when it is simply not needed IMHO. By constantly recirculating my mash water through the HERMS coil I maintain a precise temp, within 1F as measured during my last session, during the entire mash, and the water is constantly being filtered through the grain, so I do not get hot and cold spots.

I ramp up the HLT water to 173F when I mash out, I get about 1F/min rise in my MLT while doing so. Without any recirc. my HLT water will rise at 2F/min. So I simply ramp up my temp in my MLT to 173F, let it recirculate for 20 mins and then swap a hose and start my sparge.

The doohicky in the MLT I saw on another brew rig, it is a coolant hose from McMaster Carr... it works really well and holds whatever shape you bend it too, even with 175F water flowing through it.

Basically I wanted something that would allow me to efficiently hold a precise temp, make small temp adjustments when necessary, clear my wort and save propane. To make an electric HLT it seemed only logical to go ahead and drop a coil in there and build a HERMS since I already had the pump.

ScubaSteve

Well-Known Member

- Joined

- May 21, 2007

- Messages

- 3,673

- Reaction score

- 91

What's on the inside of the coolant hose? Is it copper or something? I think that'd be awesome hooked up to a qd and attached to the inner upper wall of the MT....or to a lid like you did in your build. You could even put one in the BK too if you're into recircing before chilling. Good find!

Ah, with a little digging... it's called Loc-Line

ScubaSteve

Well-Known Member

- Joined

- May 21, 2007

- Messages

- 3,673

- Reaction score

- 91

Ah, with a little digging... it's called Loc-Line

There's also some cool nozzles and spray attachments that may have potential.......

I have used the particle board for 3 years, it isnt the best, but I have yet to upgrade it. I would like to use a 1/2" plastic sheet instead of wood, that will be the next upgrade to the stand itself, but it is a lil pricey....

how about melamine? no, not the stuff in chinese milk! you can buy melamine covered particle board at any home depot. cheap and plastic-like.

explosivebeer

Well-Known Member

That's a cool setup Pol. What's the biggest batch you've done with it? Or do you just stick to 5g batches?

The Pol

Well-Known Member

- Joined

- Feb 12, 2007

- Messages

- 11,390

- Reaction score

- 117

I only do 5 gallon batches, fits the keg nicely. Also, this system has its limits... with a 120V 1500W element you cannot heat enough water fast enough for a 10 gallon batch. I heat 9.5 gallons to my strike temp, then pump over the ammount needed for strike to my MLT. Then I add 1.5 gallons of 70F water to the HLT which will stabilize my HERMS temp at about 159F (I have a spreadsheet and equation for those calculations) This way I can begin my recirc immediately. When the mash is complete, I ramp up the temp to 170F, then use the water in the HLT to sparge.

The Pol

Well-Known Member

- Joined

- Feb 12, 2007

- Messages

- 11,390

- Reaction score

- 117

Just an update... I have brewed 6 brews on this baby since I pieced it together and it has worked flawlessly. Nothing leaks, it holds my temp within .5F and allows me to mash out in a cooler without infusions!

The wort is crystal clear and brewing is finally predictable! I have been able to nail down my volumes so that I can simply start my sparge and let the HLT and MLT run dry. When they do, I have precisely the correct pre-boil volume in the kettle so that after my 90 minute boil, again, I have the exact ammount each time going to the fermentor. REPEATABILITY!

I generally document all of my brews on here, feel free to comment on them.

_________________________________________

Primary- Circle City Haus Ale

Secondary- Orange Cascade APA (dry hop)

Keg1- Centennial Blonde (On tap)

Keg2- Oktoberfest (On tap)

Keg3- Christmas Spice

Keg4- Fire In The Hole

Keg5- AIR

Keg6- AIR

Keg7- AIR

Keg8- AIR

The wort is crystal clear and brewing is finally predictable! I have been able to nail down my volumes so that I can simply start my sparge and let the HLT and MLT run dry. When they do, I have precisely the correct pre-boil volume in the kettle so that after my 90 minute boil, again, I have the exact ammount each time going to the fermentor. REPEATABILITY!

I generally document all of my brews on here, feel free to comment on them.

_________________________________________

Primary- Circle City Haus Ale

Secondary- Orange Cascade APA (dry hop)

Keg1- Centennial Blonde (On tap)

Keg2- Oktoberfest (On tap)

Keg3- Christmas Spice

Keg4- Fire In The Hole

Keg5- AIR

Keg6- AIR

Keg7- AIR

Keg8- AIR

e lo

Well-Known Member

Wow, ThePol, I love this idea. HERMS, but nice and simple. I've been having trouble hitting temps and volumes, especially now that I'm brewing in a cold garage in the Michigan fall/winter. I also really like the idea of being able to do step mashes and mashout in a cooler without infusions/decoctions. I think I might make building something like this a winter project. Can I talk you into posting a parts list, at least for the tubing and QDs?

The Pol

Well-Known Member

- Joined

- Feb 12, 2007

- Messages

- 11,390

- Reaction score

- 117

The tubing is simply the reinforced PVC from Lowes... it is 1/2" tubing to accomodate 1/2" fittings.

Here are the QD's from McMaster Carr:

#6739K59 High Flow Hose Coupling For Coolant, Plug, 1/2" Nptf Male, 3/8" Coupling Size

#6739K64 High Flow Hose Coupling For Coolant, Sleeve-lck Sckt X Barb, 3/8"cplg Sz,1/2"hose Id

Here are the QD's from McMaster Carr:

#6739K59 High Flow Hose Coupling For Coolant, Plug, 1/2" Nptf Male, 3/8" Coupling Size

#6739K64 High Flow Hose Coupling For Coolant, Sleeve-lck Sckt X Barb, 3/8"cplg Sz,1/2"hose Id

e lo

Well-Known Member

Excellent! Thank you, sir. Now to explain to SWMBO why all these packages will be showing up on our porch...

The Pol

Well-Known Member

- Joined

- Feb 12, 2007

- Messages

- 11,390

- Reaction score

- 117

Also, if you have not ordered from McMaster Carr, they ship like, next day to you and I with regular ground shipping. I love that place, they have everything under the sun! If you need anything else, let me know!

I got my HERMS coil from Morebeer!, it was very cheap compared to other stores, it is sold as a "prechiller" for wort cooling, 1/2" copper coil!

I got my HERMS coil from Morebeer!, it was very cheap compared to other stores, it is sold as a "prechiller" for wort cooling, 1/2" copper coil!

e lo

Well-Known Member

This will be my first order from McMaster, but I've heard nothing but good things about them.

I have an IC that I'll be converting to my HERMS coil, because I ordered 50 ft of tubing from coppertubingsales.com to make a super chiller/whirlpool setup. The HERMS was also my impetus to finally get off the fence and buy a pump.

Stupid expensive awesome hobbies. Just not well suited to a grad student budget.

Thanks again for your help & good info!

I have an IC that I'll be converting to my HERMS coil, because I ordered 50 ft of tubing from coppertubingsales.com to make a super chiller/whirlpool setup. The HERMS was also my impetus to finally get off the fence and buy a pump.

Stupid expensive awesome hobbies. Just not well suited to a grad student budget.

Thanks again for your help & good info!

The Pol

Well-Known Member

- Joined

- Feb 12, 2007

- Messages

- 11,390

- Reaction score

- 117

Here is the new diamond plating!

https://www.homebrewtalk.com/f11/new-diamond-plated-herms-hott-pics-88891/

https://www.homebrewtalk.com/f11/new-diamond-plated-herms-hott-pics-88891/

e lo

Well-Known Member

Nice... Diamond plating is sexy! Nice to meet another AA/Ypsi transplant.

Ran into a snag getting parts from the local HW stores today ... can't seem to find stainless washers that fit over the pipe nipples. Don't want to have to order them and pay shipping...

Ran into a snag getting parts from the local HW stores today ... can't seem to find stainless washers that fit over the pipe nipples. Don't want to have to order them and pay shipping...

e lo

Well-Known Member

Yeah, it's a PITA. I'll have to keep searching. On the upside, I did get the heating element and HERMS coil installed over the weekend, as well as wiring my new Ranco temp controller. Getting close! If I have a slow week at work this week, I might even get to try an inaugural brew with the new setup this weekend!

Couple questions for you. I read in one of your posts that you used a dip tube and stopper for your thermowell. How did you seal the end of the dip tube? Also, I have an immersion chiller that I would like to use as my heat exchanger. When I set it in my HLT the top of the coils comes to about the 6 gallon mark. Will this be a problem?

Similar threads

- Replies

- 0

- Views

- 292

- Replies

- 3

- Views

- 995

- Replies

- 2

- Views

- 341